The Custom Boxes Market is one of the leading packaging industries that offers high-quality and unique custom boxes at an affordable price. From food packaging to the packaging of cosmetic products our company covers all domains. Our packaging not only keeps your product safe but also helps you in promoting your brand.

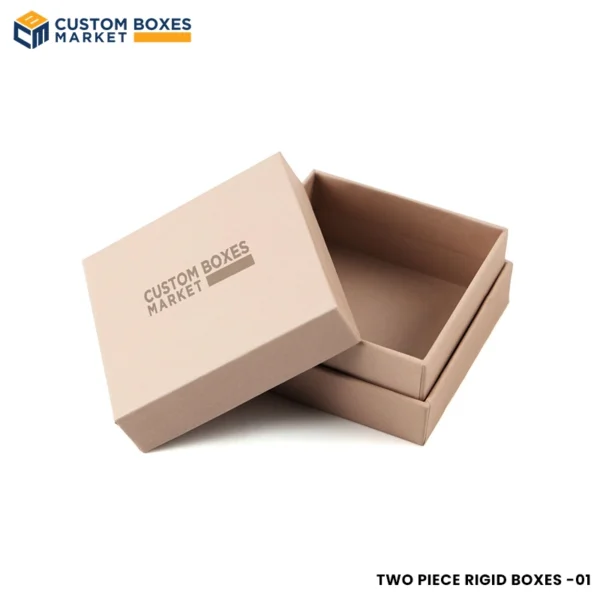

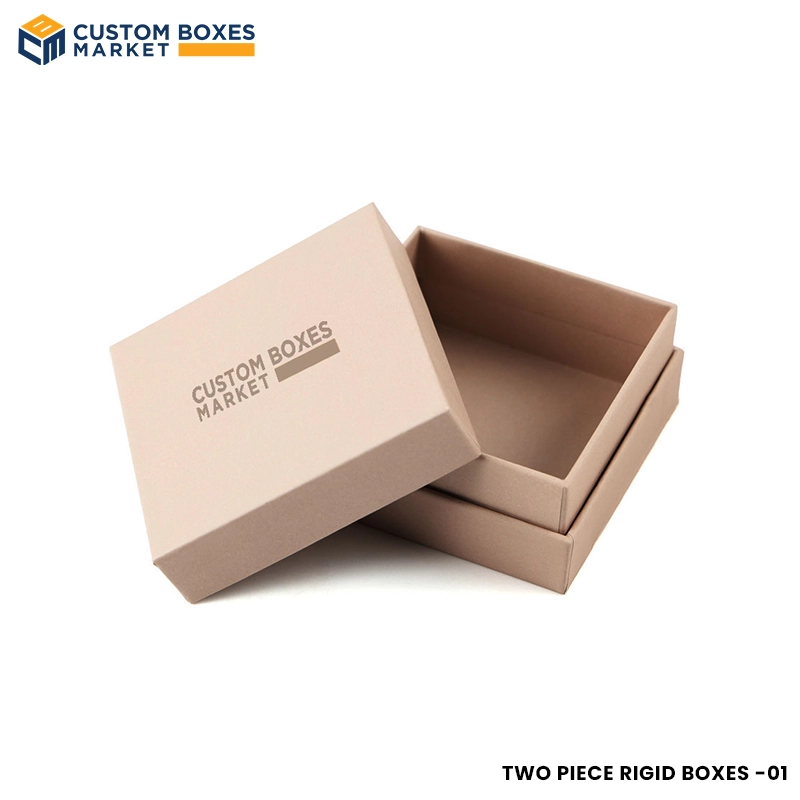

Custom Two Piece Rigid Boxes

Custom Two Piece Rigid Boxes

Get Custom Quote

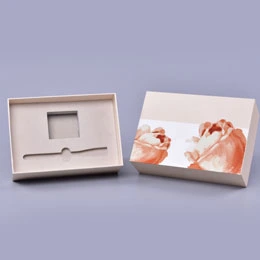

The luxury packaging dates back to the 19th century when high-end brands such as Tiffany & Co. and Cartier started presenting their products in elegant and custom-made rigid boxes. But nowadays, luxury packaging is used by almost all the brands dealing with high-end products. Two-piece rigid boxes are one of the frequently used luxury packaging options that help brands to enhance the market value of their products.

With the passage of time, luxury packaging boxes have evolved from just a storage container to a powerful promotional tool. We at Custom Boxes Market help you get the maximum benefits of the packaging that go far beyond product protection and brand promotion.

Aside from the appearance of custom two-piece rigid boxes, we ensure that you do not have to burden your resources, which is why we offer wholesale rates that keep your packaging costs in check. Let’s see what features these boxes have that make them a valuable addition.

Durable Material With Multiple GSM Options

A material is the core of your packaging. This very thing decides the overall look of your products and helps you give a luxurious appearance to it. We know that there is a huge variety of products out there and each product demands a unique packaging. Considering thai, we give use material with different GSMs for Rigid Boxes that help us to manufacture high-class packaging.

800–1000 GSM (Greyboard / Chipboard)

This material is an ideal option for 2 piece rigid boxes due to its heavy-duty nature and rigid structural core. This material gives rigidity and a stiff shape to the boxes. Greyboard ensures that your boxes are strong enough to withstand pressure and maintain structure.

Brands dealing with the following products can use this material:

- Electronics

- Perfume

- Watches

- Jewelry

- Mobile phones

120–200 GSM (Wrapping Paper – Art Paper / Coated Paper)

Paper with this GSM is used as a laminated layer that is glued onto the greyboard and gives a smooth, printable surface. This material gives a chic look to the main body of the boxes and enhances the overall appearance. This material allows high-end offset printing on rigid custom boxes and can be coated with premium coatings for a more elegant look.

If you are dealing with the below-mentioned products, then you must give the boxes a go:

- Gift sets

- Corporate kits

- Beauty products

100–120 GSM (Textured or Specialty Paper)

Sometimes brands need a little extra glam on their two-piece rigid packaging boxes, so we apply specialty paper. This paper will give a decorative inner or outer wrapping that will add a tactile feel and elevate the overall experience of the customers with your brand.

You can select this option for:

80–100 GSM (Tissue or Kraft Liner Paper)

Material with 80 to 100 GSM is used as an inner lining to give a more subtle and elegant look to the boxes. It also enhances the neatness of the boxes and adds a premium feel. This material is used when delicate or high-end products are packed.

Brands that deal with the following products can use this material:

- Luxury apparel boxes

- Confectionery boxes

- Subscription boxes

Printing For A Memorizing Look

Custom printed two-piece rigid boxes make it easy for brands to distinguish their products from rival brands. A printed design and logo will turn your packaging into a promotional tool. You can choose the printing options based on the complexity of your design and the number of boxes you are ordering at a time. This is because different printing options are suitable for different runs and designs, such as:

Offset Printing

This high-end printing is used when high-quality prints and full-color designs are required. This printing method gives photographic images with sharp details and smooth gradients. We prefer this option when we need premium aesthetic designs with a professional finish.

Screen Printing

When brands ask for bold designs and textured artwork on specialty paper, then screen printing is a go-to option. You can select these options when you need printing on specialty paper. Screen printing gives a thick layer of inks that leads to a tactile and vibrant color payoff. This also works well for minimalist design and short runs of dark color custom two-piece rigid boxes with a logo.

Digital Printing

Digital printing is an option that is used for low volumes and prototyping runs. This gives variable data easily, which is why it is used when highly customized or seasonal packaging is required. You can get quick turn-up and descent resolution for small batches of packaging at economical rates.

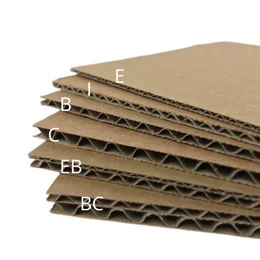

Flexographic Printing

Simple designs or corrugated style two-piece rigid boxes are usually printed with flexography printing. This option is ideal for large volumes, but it does not give as detailed designs as required. You can also opt for this printing method if you need mass production of rigid boxes with simple branding.

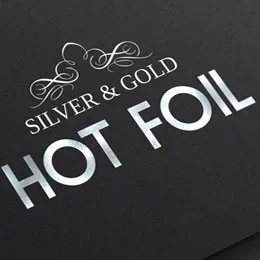

Foil Stamping (Hot or Cold Foiling)

This is a decorative add-on that is available in different colors, gold and silver are the common options. This enhances the overall look of the packaging and is a perfect option for two piece jewelry boxes. It adds a subtle shine to the specific areas of boxes and enhances your packaging sophistication.

Embossing & Debossing

Embossing and embossing are often categorized under printing options because their application style closely links to the printing process. You can use this option with traditional printing styles and complement the printed design with texture and depth. When a customer demands to enhance the sensory interaction of the design, then this is an ideal option.

UV Spot Printing

If you want to add a glossy finish to selected areas of the packaging, then choose spot UV. This printing option works well with matte lamination and provides a contrast that emphasises the design without adding additional color.

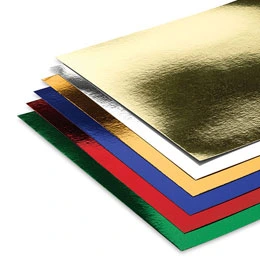

Coatings To Enhance Durability

Coatings are applied over the printed surface to enhance the surface properties of the boxes. There are several ways in which coating gives an alluring look to the packaging while protecting the material from moisture. You can select the coatings based on the nature of your product. For instance, if you want chocolate boxes, then you can choose a matte look that will enhance the sophistication of your product. Alternatively, if you’re looking for watch boxes, consider a combination of gloss and matte finishes. When you select coatings, you can influence how the color on the packaging appears and how the packaging will feel when you touch the surface.

- Gloss and matte lamination

- Gloss and matter varnishes

- Aqueous coatings

- Silkscreen coatings

- Holographic coatings

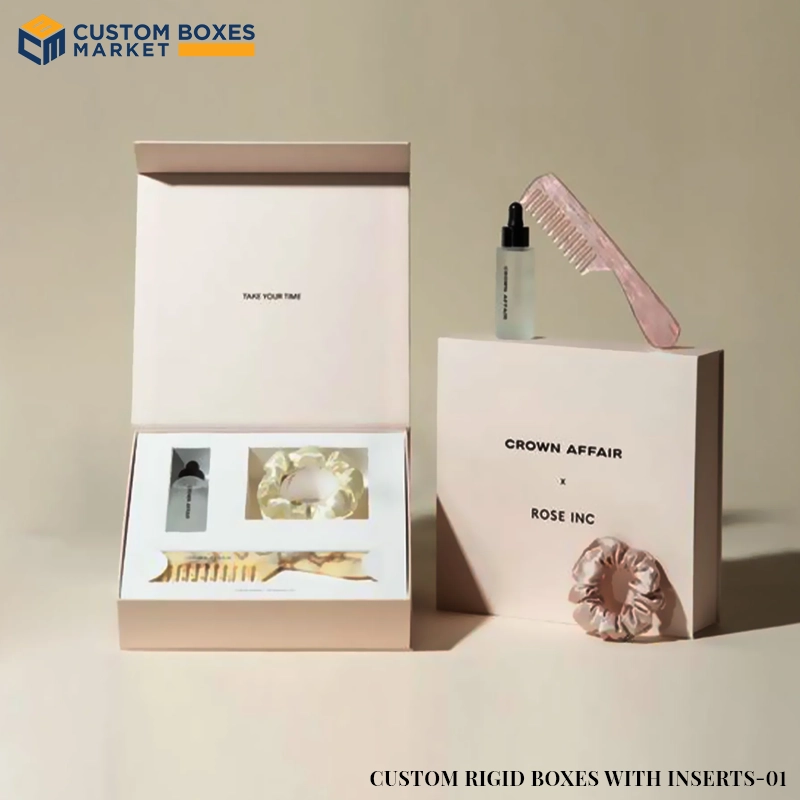

Add-Ons For Functionality And Decoration

Add-ons are decorative and functional elements on the packaging that are applied to rigid boxes. In our two-piece rigid boxes wholesale services, you will find multiple types of add-ons. These are extra embellishments that turn a basic packaging into a premium option. From tactile finishes to structural inserts, we have a plethora of options for all our customers. You can select the option that resonates with the design of your brand and make your packaging more memorable and impactful.

- Foil Stamping

- Embossing & Debossing

- Magnetic Closures

- Custom Inserts

- Spot UV Coating

- Ribbons & Pull Tabs

- Window Cut-Outs

Explore Our Premium Packaging Options

Get custom-printed two-piece rigid boxes to make sure your product looks different in the market and help you create a strong identity for your brand. At Custom Boxes Market, you will find a plethora of materials and design options that create impactful packaging. Get a quote now and let us know what type of boxes you need.

|

|

||

| Dimensions | All Custom Sizes & Shapes | ||

| Quantities | No Minimum Order Required | ||

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock | ||

| Printing | No Printing, CMYK, CMYK + 1 PMS color, CMYK + 2 PMS colors | ||

| Finishing | Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling | ||

| Included Options | Die Cutting, Gluing, Scored, Perforation | ||

| Additional Options | Eco-Friendly, Recycled Boxes, Biodegradable | ||

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) | ||

| Turnaround | 4 – 8 Business Days, RUSH | ||

| Shipping | FLAT |

Customer Review's

FAQ

Two piece boxes basically come in the tray with the attached lid. They are super convenient to use and assemble.

The process is very simple and takes no time. You just select the box style, request a free quote, then get your approval on a sample product and after 12 days receive your ordered boxes.

Yes rigid two piece boxes are perfectly acceptable for the delicate mobiles and digital devices to keep them preserved during shipping.

Yes, our company having extensive experience is certified and assured by the government. So you can completely rely on us.

We do not have any MOQ for rigid boxes. You can order any number before placing bulk orders. We also give free samples so you can see what quality we are serving.

To decide the size of the boxes, you can measure the length and width of the boxes along with the height. While placing the order, make sure that you are using the same units that you chose while measuring the boxes.

It took us 8 to 12 business days to deliver the boxes. For bulk orders, this duration may vary.

Our goal at CBM is to provide our customers with the highest quality custom boxes. Chat with us and let us know how we can help.

Do you have any queries about the customization of your boxes? Call us and get all your queries answered!

You may also like