The Custom Boxes Market is one of the leading packaging industries that offers high-quality and unique custom boxes at an affordable price. From food packaging to the packaging of cosmetic products our company covers all domains. Our packaging not only keeps your product safe but also helps you in promoting your brand.

Custom Freezer Paper

Custom Freezer Paper

Get Custom Quote

Cost Summary (USD)

Freezing foods sometimes becomes a tricky task because the freezing temperature can deteriorate the quality of the food either by increasing the moisture of the food or by declining the nutritional content of the food. In this case, freezer paper can be a useful option for freezing food as this paper sufficiently protects the foods and retains its natural texture as well as nutrition content,

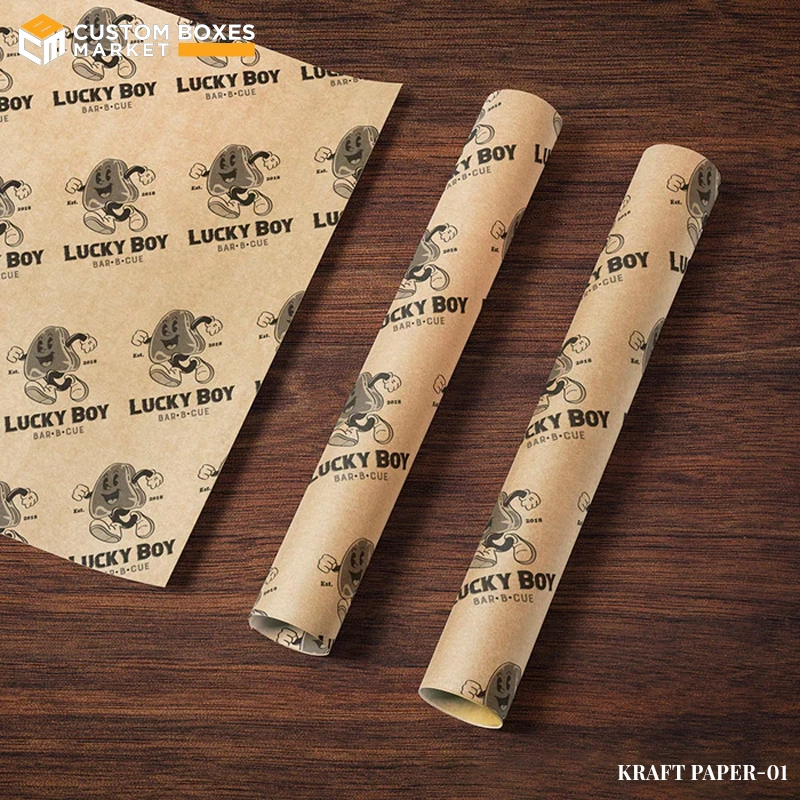

This paper is designed specifically to prevent oxygen and moisture from coming in direct contact with the food. The exceptional features of the paper prevent freezer burns and maintain the quality of food. Brands selling frozen food can use our freezer paper with a logo to promote themselves while giving a professional appearance to the packed items.

Heavy-Duty Paper To Wrap Food

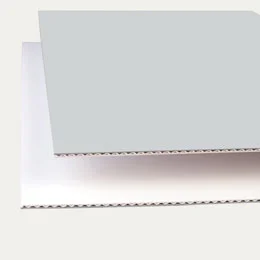

Paper to wrap food items in the freezer is heavy-duty not because of the thickness of the paper but also due to the application of coatings on one side of the paper. The thickness of the paper and the coatings protect the food from oxygen and moisture. This helps maintain the natural moisture content of the food and shields it from microbial, specifically fungal, contamination.

Manufacturing Process For Food-Safe Freezer Paper

In the production of freezer paper, chemical and mechanical processes are used. These processes are necessary to ensure the quality of freezer paper sheets. We know that the application of chemicals may render the paper unfit for direct contact with the food, that is why we thoroughly wash the chemicals after the processing and give you custom food paper that is 100 percent safe for food packaging.

Chemical Process

In this process, we extract cellulose fibers from wood chips or recycled materials. For this, we have to treat the raw material with sodium hydroxide and sulfite that break down the lignin into cellulose fibres that are then cleaned and refined. Whether you need custom wax paper or you are looking for custom parchment paper, this step is crucial for a premium quality paper.

Application Of Coating

After the pulping process, we apply food-safe coatings on the resulting kraft sheets, such as polyethylene coatings, that make the kraft paper moisture-resistant. The coatings also give strength to the paper and make it tear-resistant, protecting the food from freezer burns.

Bleaching And Refining

Bleaching agents are used to remove the natural brown color of the kraft paper. Although the natural, rustic color of the paper gives a unique appearance, when the brands have to select the paper with promotional elements and in different colors, then bleaching is done. After bleaching, the paper is further refined to make it smooth and enhance its strength so that it can be used for long-term storage.

Mechanical Process

Mechanical processes are done to prepare the pulp. In this process, paper is mixed with water to make a slurry. This slurry is then transformed into freezer paper rolls or sheets. The slurry is pressed between rollers so that the excessive water can be removed and a continuous sheet can be obtained.

Calendaring

Calendaring is a process in which the custom paper is passed through a series of rollers. These rollers smoothen the paper surface by compressing it under heat. This gives a uniform texture to the paper and makes it durable enough so that it can withstand handling during the wrapping process.

Lamination

Lamination also comes under the mechanical process in which a second layer of PE is coated over the paper, which adds to the strength and durability. This is a common option in commercially used custom freezer paper.

Types of Coatings Applied on Freezer Paper

The main purpose of personally designed freezer paper is to provide protection from moisture and oxygen, as they both contribute to freezer burns. To make sure that the paper can be used for the intended purpose, we apply different types of coatings, such as:

| Coating Type | Material | Moisture Barrier | Durability | Best Use |

| Polyethylene (PE) | Plastic | Yes | High | Freezer storage |

| Wax Coating | Paraffin/Beeswax | Yes | Medium | Meats, perishables |

| Foil Lamination | Aluminum | Yes | Very High | Long-term storage |

| Polypropylene | Plastic | Yes | High | Oxygen barrier |

Printing Methods Suitable for Freezer Paper

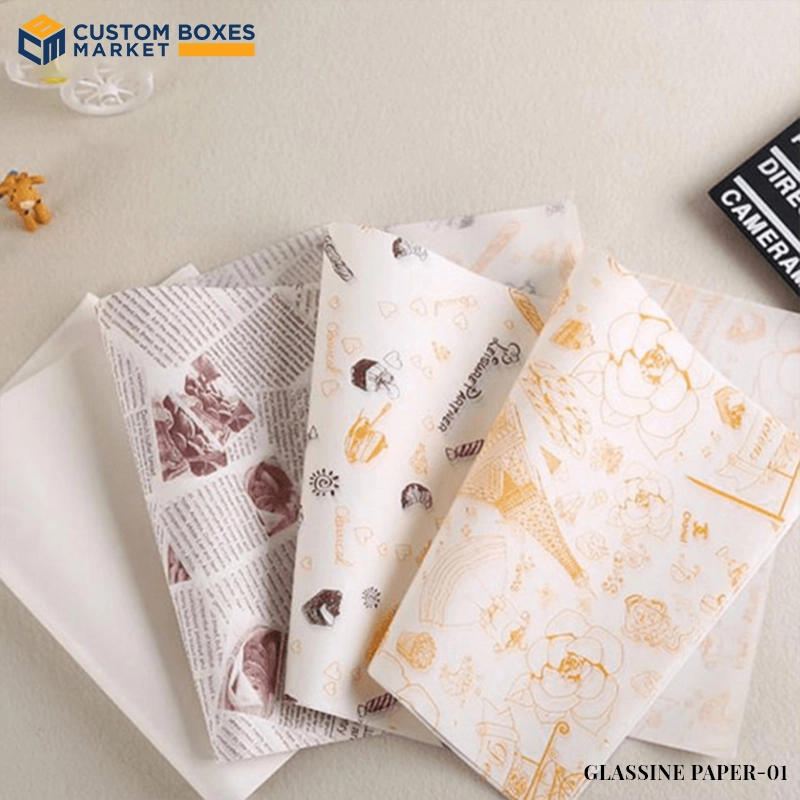

For custom printed freezer paper, we have plenty of options. You can select any of the printing methods considering the design and the branding requirements of your company. We have to use paper to wrap food items, which is why all the printing inks that we use are safe for direct contact with the food. So, in case the site in the freezer can leach any of the elements from the printed design, the quality and the safety of your food will not be compromised. Some of the suitable and un-suitable printing processes are:

| Printing Method | Type | Quality | Volume | Suitability |

| Offset Printing | High-quality | Crisp images | Large | Suitable |

| Flexographic Printing | Food packaging | Vibrant colors | Large | Suitable |

| Screen Printing | Cost-effective | Bold designs | Medium | Suitable |

| Digital Printing | Custom orders | Unique designs | Small | Suitable |

| Inkjet Printing | Not suitable | Smudges | Any | Unsuitable |

| Laser Printing | Not suitable | Melting risk | Any | Unsuitable |

| Gravure Printing | Expensive | Inefficient | Short runs | Unsuitable |

Applications Of Freezer Paper

The application of printed freezer paper is multiple and diverse in the non-food and food serving sectors. Whether you are running a deli store, your own butchery, or selling frozen food, these papers are used for easy and hygienic packaging. Some of the common applications of the paper are as follows:

Food Applications

- Meat Packaging

- Fish Packaging

- Poultry Storage

- Deli Meat

Non-Food Applications

- Crafts and DIY Projects

- Labeling and Shipping

Temperature And Moisture Resistance

Freezer paper wholesale is manufactured to withstand the extreme conditions of freezers, such as moisture and low temperatures. As the paper is designed for low temperatures, that is why you cannot use them under high temperatures such as:

- Ovens: PE Coating can melt or ignite.

- Freezer: Excellent for freezer use

- Microwave: Not microwave safe due to coating

Trustworthy Quality

At our company, we understand the importance of quality and food safety, and that is why whatever custom food wrapping paper we manufacture, we keep in mind the sustainability and food aspects of the paper. For instance, if you have to use butcher freezer paper to wrap freshly cut meat, then the chances of leaching elements to the meat increase due to high moisture. Obviously, you cannot compromise safety just for the sake of attractiveness, so for quality assurance, we only use the raw materials that are allowed by the regulatory authorities, such as:

- FDA

- FSC

- ISO 22000

- Compostability Certifications (e.g., EN 13432, ASTM D6400)

Call Us Now!

If you are looking for food-safe and FSC-approved custom freezer paper with high quality and premium appearance, then Custom Boxes Market has the solution for you. With our holistic packaging facilities, you can get the best of all custom food wraps that will help you protect and present the product like no one can, so get a quote now!

|

|

||

| Dimensions | All Custom Sizes & Shapes | ||

| Quantities | No Minimum Order Required | ||

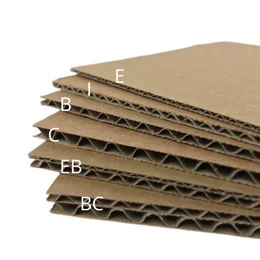

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock | ||

| Printing | No Printing, CMYK, CMYK + 1 PMS color, CMYK + 2 PMS colors | ||

| Finishing | Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling | ||

| Included Options | Die Cutting, Gluing, Scored, Perforation | ||

| Additional Options | Eco-Friendly, Recycled Boxes, Biodegradable | ||

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) | ||

| Turnaround | 4 – 8 Business Days, RUSH | ||

| Shipping | FLAT |

Customer Review's

Our goal at CBM is to provide our customers with the highest quality custom boxes. Chat with us and let us know how we can help.

Do you have any queries about the customization of your boxes? Call us and get all your queries answered!

You may also like