The Custom Boxes Market is one of the leading packaging industries that offers high-quality and unique custom boxes at an affordable price. From food packaging to the packaging of cosmetic products our company covers all domains. Our packaging not only keeps your product safe but also helps you in promoting your brand.

Custom Parchment Paper

Custom Parchment Paper

Get Custom Quote

Cost Summary (USD)

Bakeries and restaurants need custom parchment paper for baking food and promoting their brand. This paper is manufactured in such a way that makes it highly resistant to heat and enhances its non-stick nature. At commercial levels, brands select the paper to promote their brand and get the maximum sales. The quality of papers directly influences the:

- Product performance

- Brand reputation

- Compliance

As a parchment paper wholesale provider, we know what the challenges brands are facing. From high-end silicon coating to the application of promotional elements, our company does everything in perfect alignment. With our diverse range of customization and premium raw materials, you can get the perfect packaging paper for your brand.

What Is Parchment Paper?

It is a custom food wrapping paper that is manufactured with kraft material coated with silicone. Parchment is used as a pan liner for baking and serving piping hot meals. The paper undergoes hydrolysis that partially gelatinizes the cellulose microfibrils. This gelatinization gives a dense network of grease-resistant pulp. At our company, we make sure that this process is controlled to give a constant porosity and high tensile strength. This process gives paper that prevents the following issues:

- Oil-bleed failures

- Inconsistent non-stick behavior

- Weak heat resistance

- Paper tearing under stress

- Silicone migration concerns

- Certification gaps for food-contact safety

The quality control of this process is necessary to prevent issues at the molecular level. Hydrogen bonding between fibers gives a cross-linked structure during the parchmentization process. The application of silicone coating on parchment paper further makes the paper’s structure complex and influences the temperature curing and uniformity, along with release consistency. By getting printed parchment paper for baking and packaging, you can get the following benefits:

- Reduce product returns

- Maintain regulatory trust

- Deliver predictable customer experiences at an industrial scale

- Reduce the carbon footprint of your brand

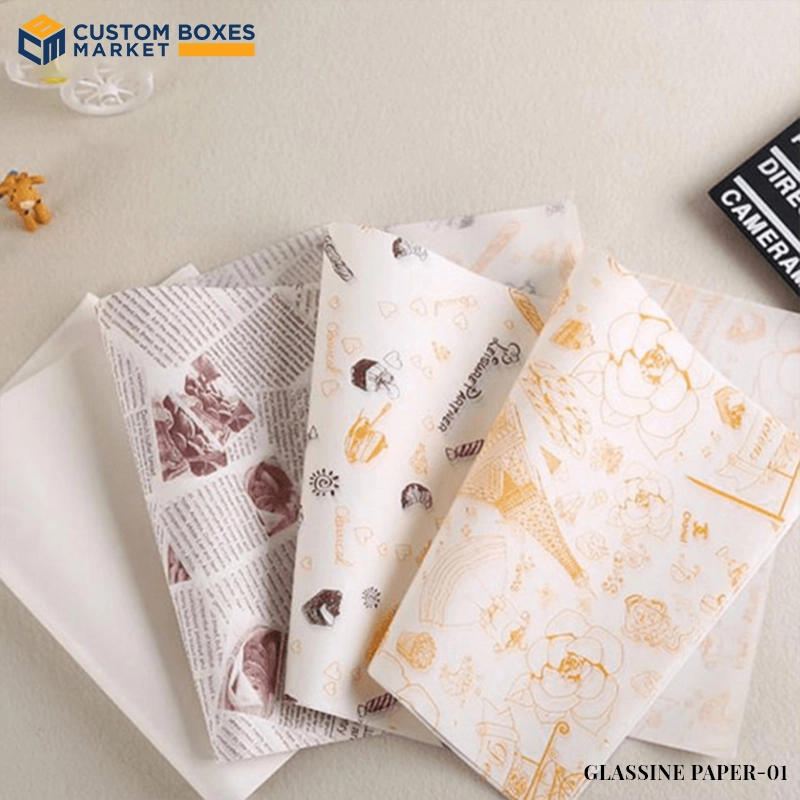

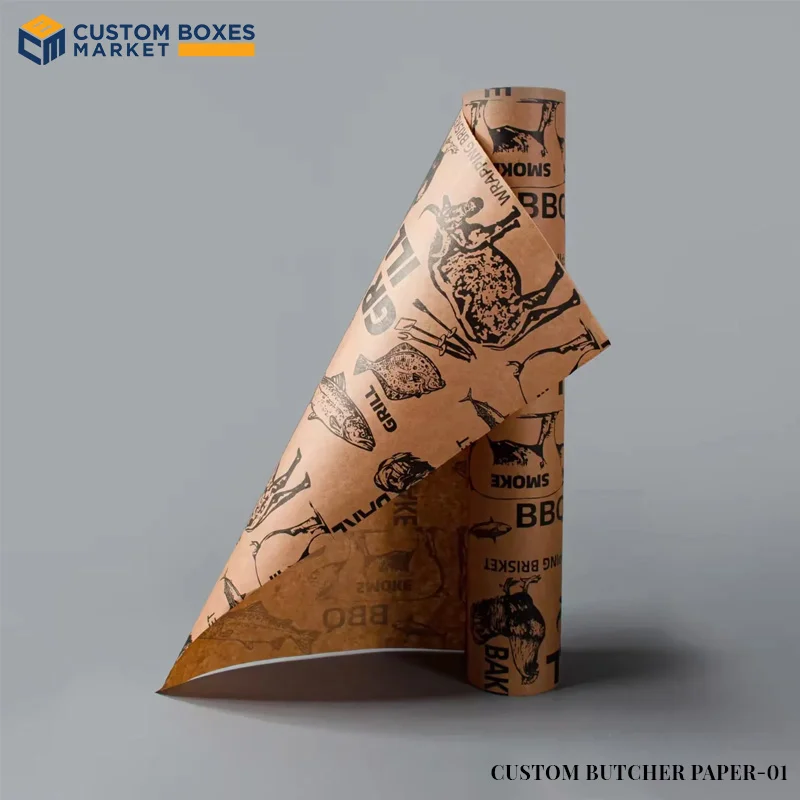

This paper differs from the rest of the custom papers due to the following reasons:

| Paper Type | Core Use | Surface Trait | Heat Behavior | Oil Resistance |

| Parchment Paper | baking liners | silicone coated | high temperature | moderate barrier |

| Wax Paper | cold wraps | wax coated | low tolerance | strong barrier |

| Burger Paper | food wrapping | breathable surface | medium tolerance | light barrier |

| Grease Paper | oil absorption | smooth fiber | low tolerance | absorbent structure |

| Kraft Paper | packaging wraps | uncoated fibers | ambient safe | minimal barrier |

| Butcher Paper | meat wrapping | porous strength | smoke friendly | controlled breathability |

| Deli Paper | serving liners | moisture resistant | low temperature | light barrier |

Material For Parchment Sheets

The base material for parchment is a highly pure pulp of cellulose that is obtained from bleached and unbleached kraft pulp. One of the major issues that brands have to face with the paper is that it often contains residues. These residues reduce the quality of pulp and the resulting paper. Our company has advanced manufacturing facilities that give paper that is free from

- Uneven hydrolysis during parchmentization

- Weaker hydrogen bonding in the fiber matrix

- Color variation and yellowing at high temperatures

- Reduced grease resistance

- Variable stiffness and drape behavior

β-1,4-linked D-glucose chains form the microfibrils in cellulose that form the smooth structure. The process of hydrolysis weakens the amorphous regions that swell in the fibrils. After these fibrils refuse and recrystallize to give an even more refined paper. We make sure that there are no impurities in the paper that can interfere with the fusion and lead to patchy paper with micro-pososity. Our advanced manufacturing process for custom printed parchment paper production controls the following specifications of the material:

- Cellulose purity ≥ 92–95%

- Low residual lignin index

- Controlled fiber length distribution

- Moisture 4–6% that stabilizes hydrogen bonds

- Basis weight tolerance ± 2–3 g/m²

Application Of Silicone Coatings

Most modern parchment papers use silicone release coatings to enhance the non-stick nature of the paper. The silicone coating consists of a polydimethylsiloxane network that reduces the surface energy and makes it easy to release the paper from the utensil or baking pan. The average structure of the paper goes through the following at the time of curing:

- Silanol groups cross-link, forming a Si-O-Si lattice

- The lattice partially anchors into cellulose hydroxyl groups

- A low-surface-energy film forms

- This prevents protein and sugar adhesion

- Low surface energy also prevents the adhesion of oils

With the high-end service of our company, we evenly coat the paper to prevent inconsistent release of the paper. Unlike greasepaper, this coating prevents peel failure as the anchorage of the coating is high. The specifications of your silicone coatings are as follows:

- Coat weight is0.5–1.2 g/m²

- Uniformity across the web profile

- Platinum-catalyzed or thermal curing at controlled temperatures

- Cross-link density validation

- FDA and EFSA food-contact compliance records

Our company gives analytical validation and eliminates an inconsistent user experience with your brand.

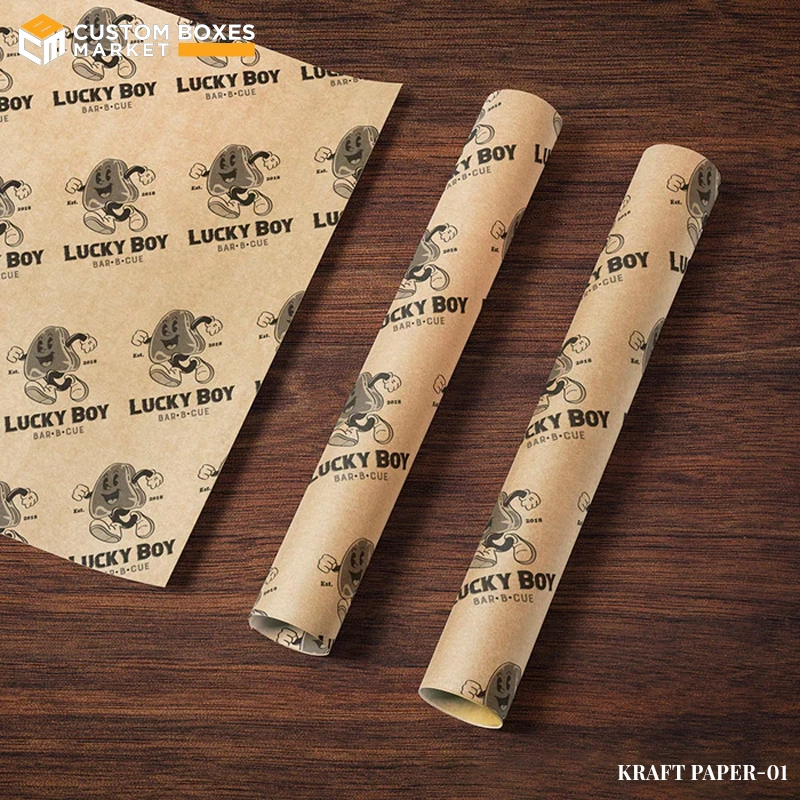

Printing Processes Without Damage Release Properties

Printed parchment paper for food is used for branding and presentation purposes. Oven use instructions and batch identification properties are also added to the paper. Nonetheless, the use of printing comes with certain risks. The inks can interact with silicone and interfere with the release properties. Aside from this, ink increases the surface properties that impact the sticking properties of the paper. Our company makes sure to prevent all these issues and uses the following ink methods:

- Flexographic printing

- Gravure printing for high-volume precision

- UV-curable inks designed for low-energy surfaces

- Water-based inks with silicone-compatible binders

Applications Of Customized Parchment Paper Sheets

Food is the major sector in which custom-printed parchment paper is manufactured. The heat-resistant and non-stick nature of parchment makes it a perfect option for baking and wrapping hot food items. Some of the common applications are as follows:

- Baking liners

- Food wrapping and hot-hold packaging

- Industrial release liners (rubber, resin, composites)

- Confectionery and dairy processing

- Air-fryer and oven-ready packaging

Typical Brand Risk Zones

- High-fat bakery products lead to an oil penetration risk

- High-sugar items can cause caramel adhesion

- Frozen-to-oven cycles can lead to thermal shock and tearing

Our company has excellent knowledge of material science and is perfectly aware of material sourcing. For us, price is not the only procurement process. We also consider quality without breaking the bank.

Book Your Order Now!

Book your order of custom parchment paper at Custom Boxes Market and avoid the technical errors your brand is facing. We give paper with perfect molecular chemistry and high-end promotional potential so you can get the maximum benefit without breaking the bank.

|

|

||

| Dimensions | All Custom Sizes & Shapes | ||

| Quantities | No Minimum Order Required | ||

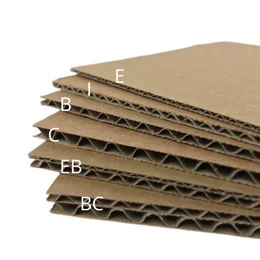

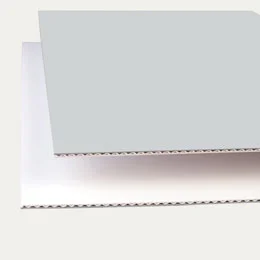

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock | ||

| Printing | No Printing, CMYK, CMYK + 1 PMS color, CMYK + 2 PMS colors | ||

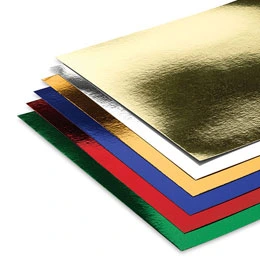

| Finishing | Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling | ||

| Included Options | Die Cutting, Gluing, Scored, Perforation | ||

| Additional Options | Eco-Friendly, Recycled Boxes, Biodegradable | ||

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) | ||

| Turnaround | 4 – 8 Business Days, RUSH | ||

| Shipping | FLAT |

Customer Review's

FAQ

You can book a minimum order of 30 rolls at a time.

Yes! We have the option of two to full color printing.

Yes! You can get any design of your brand printed on the paper, including the logo.

Yes! We give free online consultations. You can fill in the questionnaire, and our customer care representatives will contact you.

Yes! Upfront is necessary before the production of bulk orders.

Our goal at CBM is to provide our customers with the highest quality custom boxes. Chat with us and let us know how we can help.

Do you have any queries about the customization of your boxes? Call us and get all your queries answered!

You may also like