The Custom Boxes Market is one of the leading packaging industries that offers high-quality and unique custom boxes at an affordable price. From food packaging to the packaging of cosmetic products our company covers all domains. Our packaging not only keeps your product safe but also helps you in promoting your brand.

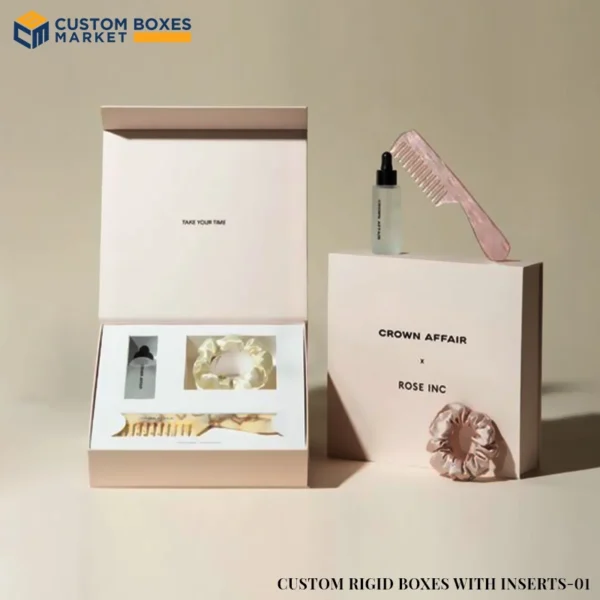

Custom Rigid Boxes with Inserts

Custom Rigid Boxes with Inserts

Get Custom Quote

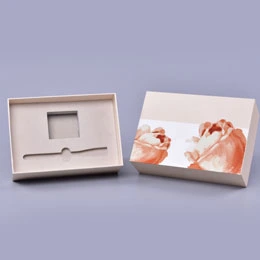

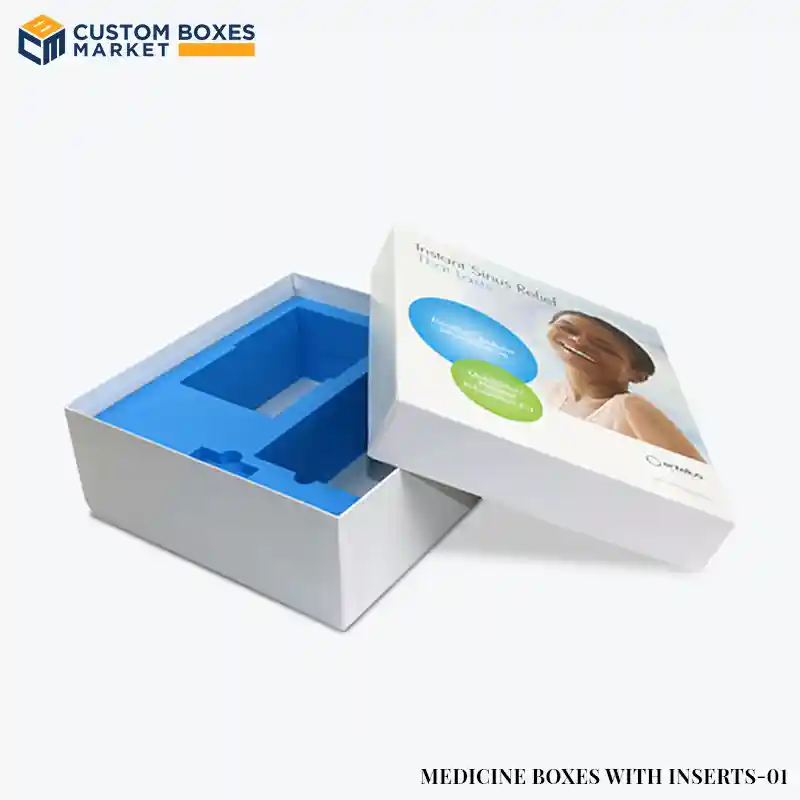

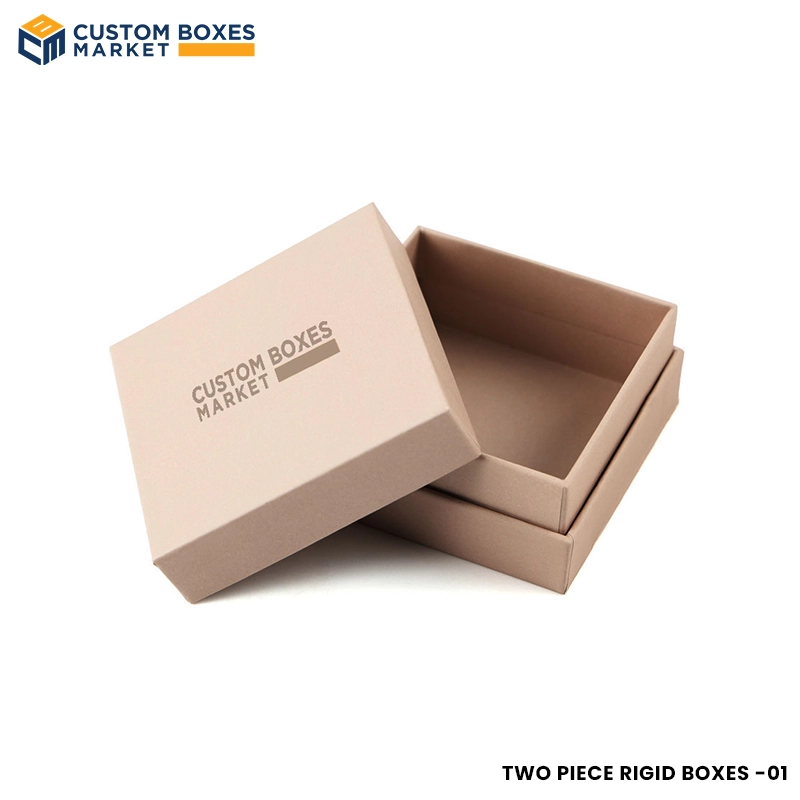

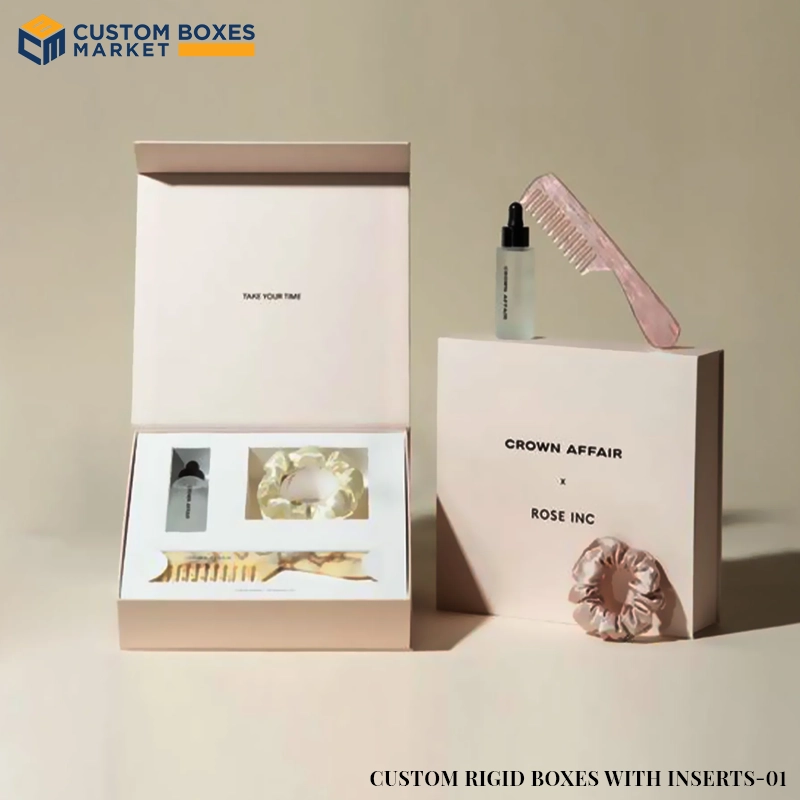

Luxury brands require packaging that is easy to use for customers and made from high-end materials. Custom Rigid Boxes with Inserts provide the same features that also protect the content during transportation. These boxes are customizable and can be crafted into any shape, size, printing, coatings, and laminations.

The use of these boxes ranges from cosmetics, watches, and high-end clothing to perfume and valuables gifts. Moreover, these boxes can be recycled as CustomBoxesMarket uses natural materials for protection. Rigid insert boxes provide an all-in-one solution for brands who want to reflect sophistication and premium from their packaging.

Raw Materials Of Custom Rigid Boxes With Inserts

Different rigid materials are available in the market but you should choose after analyzing the product type and the quality of packaging you desire. Rigid is 100% eco-friendly material extracted from natural wood and then processed with other materials. Below you can read which materials are used in the composition of rigid Personalized Rigid Boxes with Inserts for you:

- Wood pulp: Wood pulp is used to make paper-based raw material. Pulp is extracted from hardwood and softwood trees which provides a smoother finish to the material.

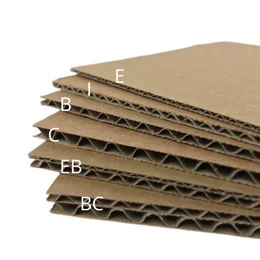

- Recycled paper fiber: Some producers use recyclable materials like chipboard or corrugated fiberboard to make rigid materials that help in reducing environmental footprint.

- Adhesives and coatings: Adhesives and coatings are used for adhering wrapping paper and to make the paper more strong and protective.

Printing Techniques For Brand Consistency

Selecting a high-end material for packaging but neglecting the printing process is an unwise choice. We offer high-quality and updated printing techniques so you can select according to the quantity and quality required. Also, Printed Rigid Boxes with Inserts with decorative branding elements enhance the fascinating look of the product. Different printing techniques are given below:

Offset Printing

Offset is the most commonly used for printing high-end packaging like rigid boxes. This printing technique is known for producing sharp details and intricate designs on the material’s surface. Inks are transferred to a rubber blanket and then onto the paper in offset printing.

Digital Printing

Digital printing is ideal when you want a small number of boxes to be printed. This printing method enables brands maximum customization and you can even change the design at any time without any hassle. So if you want flexible and short-run printing then digital printing is the right choice.

Flexographic Printing

Unlike digital, flexography is ideal for large-run printing. If you want a large quantity of boxes to be printed then this method is a cost-effective option for you. Flexo printing uses special plates for printing attractive designs on rigid material.

Screen Printing

Screen printing uses a special screen often called mesh to produce simple to complex designs. This printing method is usually used for speciality applications where raised and textured designs are required. Screen printing is a cost-effective technique for large-run prints.

Pre And Post-Print Coatings For Rigid Boxes With Inserts

Coatings are used to enhance the durability and visual apparel of packaging. They help in safe and sound delivery and prevent scratches, smudges, and fingerprints. There are two main categories of coatings. One is preprint which is applied before the printing process and the other is post-print which is, as the name suggests, applied after printing. Here is how coatings end up with luxury rigid boxes:

Preprint Coatings

The main purpose of pre-print coating is to provide an additional layer of protection before printing. They also help with a smooth and polished printing process. Preprint coating helps prevent moisture and grease that may occur during delivery in bad weather conditions. Here are the two main pre-print coatings we provide:

- Primers

- Barrier coatings

Postprint Coatings

Postprint coatings are used to achieve the desired appearance of the packaging. Whether you want a gloss or a non-reflective appearance, we can make it happen for you. Moreover, some coatings can be applied to only some spots of the box to highlight the main elements. The list of post-print coatings that we provide is as follows:

- UV coating

- Matte coating

- Gloss coating

- Soft touch coating

Add On Elements For A Luxurious Appearance

Add-on not only enhances the visual appeal but also offers functionality. So if you want both aesthetic and practical benefits then spending some dollars on additional elements would be worth it. From magnetic closure rigid boxes to personalized lids, the following are the options we provide our valuable clients:

- Embossing/debossing

- Foil stamping

- Holographic effect

- Die cut windows

- Magnetic closure

- Ribbons and handles

Types Of Inserts For Rigid Boxes

Whether you are opting for rigid gift boxes or for the packaging of your high-end retail items, our versatile insert types will entice your recipients. We offer simple to premium inserts so you can choose according to your budget and product type. Here are different inset options you can choose from:

- Foam inserts: Provides cushioning affection with efficient display.

- Cardboard inserts: Protect products during delivery and enhance the unboxing experience.

- Paper inserts: Cost-effective manner of productive promotion with printed paper inserts.

- Molded pulp inserts: Made from natural materials, ideal for brands that give priority to sustainability.

Collaborate With Us For High-End Packaging

CustomBoxesMarket is the most experienced Rigid Boxes with Inserts Wholesale provider in the whole of the United States. We offer luxury rigid packaging for under $20 without compromising on quality. We offer customers a fair deal to elevate their brand with the following flexible services:

- Free delivery

- Free design assistance

- Fastest turnaround

- Free quotation mark

- Minimal costs

- Free 3D samples

- Special 50% off on bulk orders

- No hidden charges

- Eco-friendly manufacturing system

Submit A Quote Now!

Just search for rigid boxes with inserts nearby and our website will pop up first on the list. Submit a free quote or call our customer service to confirm your order.

|

|

||

| Dimensions | All Custom Sizes & Shapes | ||

| Quantities | No Minimum Order Required | ||

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock | ||

| Printing | No Printing, CMYK, CMYK + 1 PMS color, CMYK + 2 PMS colors | ||

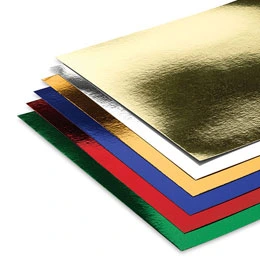

| Finishing | Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling | ||

| Included Options | Die Cutting, Gluing, Scored, Perforation | ||

| Additional Options | Eco-Friendly, Recycled Boxes, Biodegradable | ||

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) | ||

| Turnaround | 4 – 8 Business Days, RUSH | ||

| Shipping | FLAT |

Customer Review's

FAQ

Yes, you can always come up with your own design. However, we offer free-of-cost design assistance from expert designers hired at our place.

We accept 100 custom boxes at a minimum and above you can order as many as you desire.

Yes, we offer matte and gloss lamination techniques that add protection and visual appeal to your packaging.

We use sustainable and long-lasting printing inks that will keep your printing bright for a longer period. The following are inks we use:

- Water-based inks

- Soy-based inks

- Vegetable-based inks

- Petroleum-based inks

Our goal at CBM is to provide our customers with the highest quality custom boxes. Chat with us and let us know how we can help.

Do you have any queries about the customization of your boxes? Call us and get all your queries answered!

You may also like