The Custom Boxes Market is one of the leading packaging industries that offers high-quality and unique custom boxes at an affordable price. From food packaging to the packaging of cosmetic products our company covers all domains. Our packaging not only keeps your product safe but also helps you in promoting your brand.

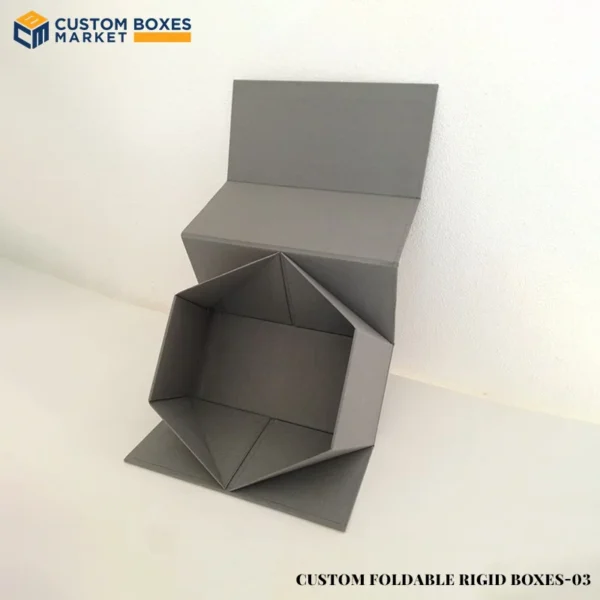

Custom Foldable Rigid Boxes

Custom Foldable Rigid Boxes

Get Custom Quote

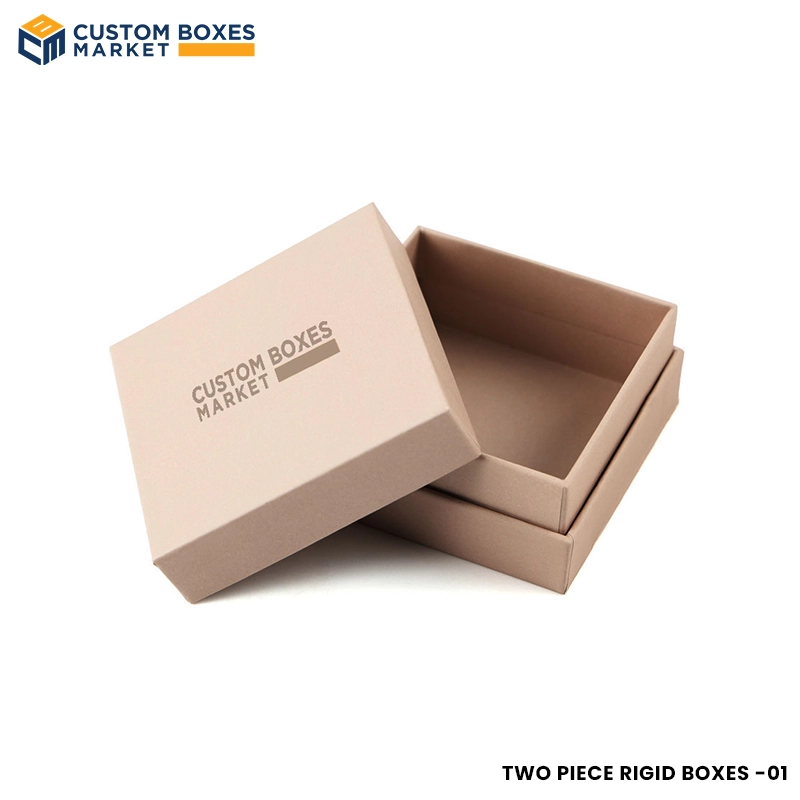

If you are looking for a premium packaging solution that can help you drive sales and increase product protection then Custom Foldable boxes are the perfect solution for your packaging needs. These packaging boxes offer convenience and easy assembly. They are designed to house various high-end, e-commerce and retail products.

CustomBoxesMarket is a one-stop packaging solution with diverse customization options. We offer custom sizes and designs to meet your product needs. Plus, all our services are sustainable and highly affordable. So, avail the best of our options and stand out in the marketplaces.

Why Use Rigid Foldable Packaging Boxes?

Customized Foldable Rigid Boxes are also called collapsable boxes. They serve excellently in various industries. They are safer to use and keep the products in pristine condition. They do not mold or collapse and prevent any external damage. The following are the reasons that make foldable rigid packaging a necessity for brands.

| Flexibility | They can accommodate a variety of products from heavier to fragile ones. We also design them with handles or locking mechanisms for easy carrying. |

| Safety | Protect products during transit and sturdy walls of boxes create a strong environment. |

| Ease of use | A foldable rigid box can make packing and unboxing. They are user-friendly. |

| Brand Promotion | They can be customized with your logos and brand themes. |

| Sustainable | All the services maintain sustainability and safety for the earth. |

Unique Design Of Rigid Foldable Packaging Box

Rigid Foldable Boxes are designed to store or ship compactly. This feature makes them a popular choice for manufacturers and various other businesses. They are easily assembled by folding the pre-creased lines and locking the panels into place. Hence creating a rigid and sturdy structure. The distinct structure of these collapsible boxes is discussed:

- Box body: this is known as the frame, also called the body of the box.

- Base and lid flaps: These are connected to the box body.

- Dust Flaps: They prevent the external elements from entering the box and keep the lid from breaking.

- Tuck-in flap: This flap closes the top of the box.

- Panels: The box consists of six panels.

Manufacturing Process Of Foldable Rigid Boxes

Foldable rigid packaging boxes play a crucial role in premium packaging specifically for luxury products, electronics, cosmetics, and other high-end retail products. Rigid materials enhance the structural integrity and aesthetic appeal of products. They ensure the product’s safety, add elegance, and communicate brand quality. The manufacturing process of Rigid materials for foldable boxes includes the following steps:

Pulping Process

During this process, wood chips are processed in the large pulping machine and transfer the material into to pulp. Chemical or mechanical methods are used according to the requirements.

Forming & Processing

The pulp is transformed into sheets. The sheets are pressed to remove excess water and can vary in thickness due to the product requirement. The process involves calendaring where the paperboard is run through rollers to achieve the desired smoothness of the paper.

Layering

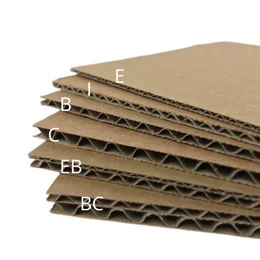

For corrugated paperboard, the process involves layering of different sheets together. A fluted sheet of paper present between to linerboards offers extra cushioning to products. These layers are joined together with the use of adhesives.

Cutting and Scoring

After the formation of smooth sheets, they are cut and scored into the desired shapes and sizes according to the requirements of the custom box. This process involves die cutting machines that can create complex shapes and cuts in rigid material. However, scoring is done to create fold lines so that the material can be easily folded into the box.

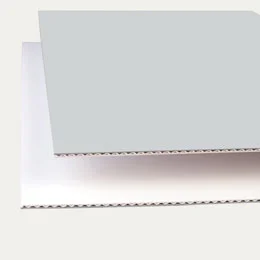

Pre Printing Coatings For Rigid Packaging

Preprinting coatings are done to improve the quality of the material and make it smooth enough for various printing processes. They also protect the printing inks from damage. They offer sharper images and increase the durability of packaging boxes. Given are the pre-printing coatings for product packaging boxes:

- Primers: We utilize primers to ensure that the ink adheres properly to the surface. This is particularly important for materials like SBS which consist of extremely smooth surfaces for ink to bond effectively.

- Barrier Coatings: These barriers prevent moisture from damaging the materials during production. They are commonly applied for food packaging or other fragile items that are exposed to moisture during transit.

Printings For Custom Foldable Rigid Packaging

Different printings are used to give a sleek look to the foldable rigid packaging boxes. Our manufacturing team uses innovative printings that give smooth and precise results. We produce high-quality images, texts, logos, and color themes to make your packaging dominant on the market shelves. Plus, we use eco-friendly inks that are safe and recyclable. They include water-based, soy-based, algae-based, and petroleum-based. We give the following mechanisms for custom printed boxes:

- Offset Printing

- Digital Printing

- Screen Printing

- Flexography

- Gravure Printings

Trendy Printing Colors

Color plays an important role in bringing life to the packaging boxes. So, we use advanced color processing modules that are popular in the industry and give eye-catching combinations that grab the attention of customers.

- PMS ( Pantone matching system)

- CMYK ( cyan, magenta, yellow, key)

- RGB ( red, green, blue)

Post Printing Coatings

We apply these coatings to enhance the visual appeal of the custom rigid boxes. These coatings give a unique look to the product and make it stand out. Our coatings offer durability and longevity. Following are the coatings that you can opt for:

- UV Coating

- Matte Coating

- Soft Touch Coating

- Anti Scratch Coating

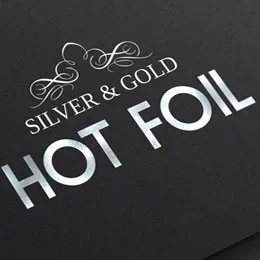

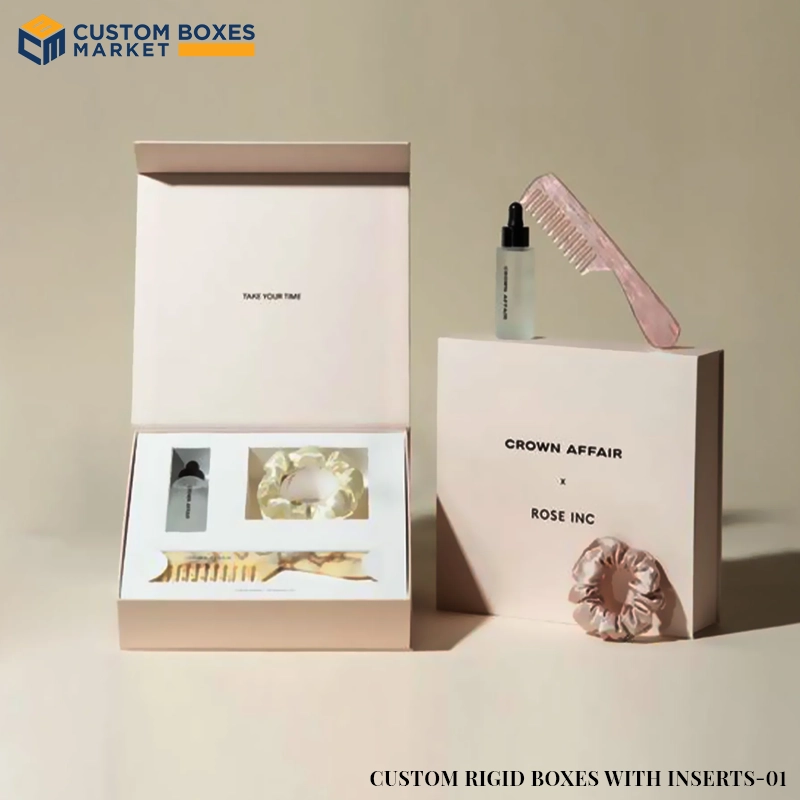

Additional Embellishments

We offer a variety of decorative elements for personalized rigid gift boxes to enhance the functionality and aesthetic appeal of the packaging boxes. They give an attention-grabbing appeal to the boxes and persuade customers to make immediate buying decisions. We offer the following additions:

- Embossing

- Debossing

- Foil Stamping

- Spot UV

- Die cut windows

- Magnetic Closures

- Ribbons & Handles

Put Your Faith In Us!

Increase your brand perception and product sales with custom foldable rigid boxes bulk and stand out in the markets of the US. CustomBoxesMarket provides unlimited customization options to our customers without compromising quality. Plus, we provide the following perks:

- High product presentation

- Eco-friendly packaging

- Free deliver

- Free design support

- High turnaround times

- 3D Prototypes

- No Plate Or Die Charges

- Wholesale options

- Informative Packaging

So, why delay more? Ping us now and make your brand the first preference for every customer!

|

|

||

| Dimensions | All Custom Sizes & Shapes | ||

| Quantities | No Minimum Order Required | ||

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock | ||

| Printing | No Printing, CMYK, CMYK + 1 PMS color, CMYK + 2 PMS colors | ||

| Finishing | Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling | ||

| Included Options | Die Cutting, Gluing, Scored, Perforation | ||

| Additional Options | Eco-Friendly, Recycled Boxes, Biodegradable | ||

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) | ||

| Turnaround | 4 – 8 Business Days, RUSH | ||

| Shipping | FLAT |

Customer Review's

FAQ

We offer no less than 100 boxes.

All our materials are nature-friendly. They are obtained from pure wood pulp that is recyclable.

Yes, you can request a sample but we provide free samples for the order of $4000 but for a generic box, we charge $9. However, the prices vary for additional unique features.

We deliver your order in 6 to 8 working days. We also deliver urgent orders with additional charges.

Our goal at CBM is to provide our customers with the highest quality custom boxes. Chat with us and let us know how we can help.

Do you have any queries about the customization of your boxes? Call us and get all your queries answered!

You may also like