Trusted by

Discover Our Popular Custom Rigid Boxes

Description

When it comes to luxuriously presenting the products, the first thing that comes to mind is the use of rigid boxes. Custom Boxes Market manufactures these boxes with premium quality material that retains the delicate product quality and your unique status in the market.

Unlike folding cartons that can be kept flat and folded for storage, boxes made with rigid material come in pre-assembled form and do not collapse. These boxes are one of the sturdiest additions to your brand and are quite thick, durable, and highly customizable. That is why most of the brands use these boxes whenever it comes to selling luxury products such as watches or jewelry.

Custom rigid packaging is manufactured with a chipboard that ensures that the product inside the box remains secure. By getting these boxes from our company, you can get the Chinese to avail boxes made with different subtypes of chipboard based on the specific requirements of your brand.

Types Of Custom Rigid Boxes

The packaging industry has advanced a lot, and now there are several modes to incorporate innovation in the boxes. This is because customers have a lot of tendency toward attractively presented products. Using the different types of boxes, you can make your product distinct from others and increase your sales dramatically. As a custom rigid packaging wholesale manufacturer, we give the following types of boxes made with rigid material:

| Box Type | Opening Style | Protection Level | Common Uses | Closure Type | Visual Appeal |

| Setup Boxes | Lift Lid | High Protection | Luxury Watches | Separate Lid | Premium Look |

| Magnetic Boxes | Magnetic Flap | Secure Closure | Electronic Gadgets | Hidden Magnets | Elegant Finish |

| Drawer Boxes | Slide Open | Moderate Protection | Beauty Products | Pull Ribbon | Modern Style |

| Sleeve Boxes | Slide Sleeve | Added Layer | Perfume Packaging | Friction Hold | Versatile Design |

| Slipcase Boxes | Tray Insert | Dual Protection | Book Collections | Sleeve Cover | Classic Touch |

| Flip Boxes | Hinged Lid | Firm Protection | Retail Packaging | Magnetic Assist | Sleek Appearance |

Durable Material Used For Rigid Packaging

The strength and the quality of the boxes depend only on the quality of the raw material used to manufacture them. As the main material used in the manufacturing of custom rigid packaging bulk is chipboard, it must be of high quality. This material is available in various sub-types that vary in their thicknesses and durability. Whether you need custom sleeve & tray rigid boxes or a flip-top one, we have the best option at your disposal.

| Chipboard Type | Box Application | Strength Level | Visual Finish | Brand Positioning | Use Category |

| Single Ply | Rigid Apparel | Medium Strength | Smooth Surface | Retail Branding | Daily Packaging |

| Multi Ply | Luxury Rigid | Maximum Protection | Premium Finish | High End | Gift Packaging |

| Gray Board | Rigid Kraft | High Strength | Natural Texture | Sustainable Luxury | Eco Packaging |

| White Board | Rigid Setup | Firm Structure | Clean Coating | Professional Branding | Retail Display |

| Multi Ply | Magnetic Rigid | Secure Build | Seamless Look | Luxury Presentation | Premium Electronics |

| White Board | Invitation Rigid | Stable Form | Elegant Surface | Event Branding | Formal Packaging |

| Gray Board | Book Style | Durable Build | Matte Texture | Classic Branding | Collection Storage |

| Multi Ply | Rigid Candle | Heat Resistance | Refined Finish | Boutique Branding | Home Fragrance |

| Single Ply | Foldable Rigid | Light Structure | Plain Finish | Cost Efficient | Promotional Boxes |

| Multi Ply | Collapsible Rigid | Strong Panels | Luxury Feel | Premium Shipping | Space Saving |

| White Board | Rigid Lids | Solid Base | Polished Look | Corporate Identity | Business Packaging |

| Gray Board | Setup Rigid | Tough Build | Raw Finish | Minimal Branding | Reusable Boxes |

Printing And Coating Options For Custom Rigid Boxes

The design of custom printed rigid packaging elevates the overall appearance of the boxes and helps you grab the attention of the customer easily. You can get any of the printing options from our company and elevate the sales of your company. We give the following options for printing:

- For precision and detailed graphics, we refer our customers to select offset printing.

- If you need a small run with inkjet or laser technology, then digital printing is suitable. This is because there will be no need to invest in a printing setup.

- For thick consistency and vibrant colors, we give the option of screen printing

CMYK and PMS in Rigid Boxes and Their Design Impact

CMYK is the printing process that is suitable for photographic images and complex artwork. This is the best option for a smooth color transition and is cost-effective for large runs. If you are looking for full color apparel boxes and rigid setup boxes, then CMYK must be your go-to choice.

On the other hand, PMS is an ideal option for accurate brand colors. If you want consistency across all the batches, then PMS is the best. It gives exact colors to logos and other branding designs. The selection between the two impacts the visual sharpness and consistency of colors, which affects the perceived value of the brand.

The Use Of Coatings On Rigid Boxes and What They Indicate

The applications of coating are the last thing that we do to enhance the protective ability of the boxes. There are so many coatings, and the selection must be done based on the type of look you need for your product. Some of the coatings enhance the durability of boxes, while others increase appearance. You can select coatings by considering the following options for simple to custom two piece boxes or lid & tray rigid boxes:

- Matte coating indicates sophistication and reduced glare

- Gloss coating represents vibrancy and shine

- Soft touch coating conveys a premium tactile experience for high-end branding

- Aqueous coating signals eco awareness

- UV coating highlights specific design elements like logos

- Lamination coatings indicate moisture resistance and structural reinforcement

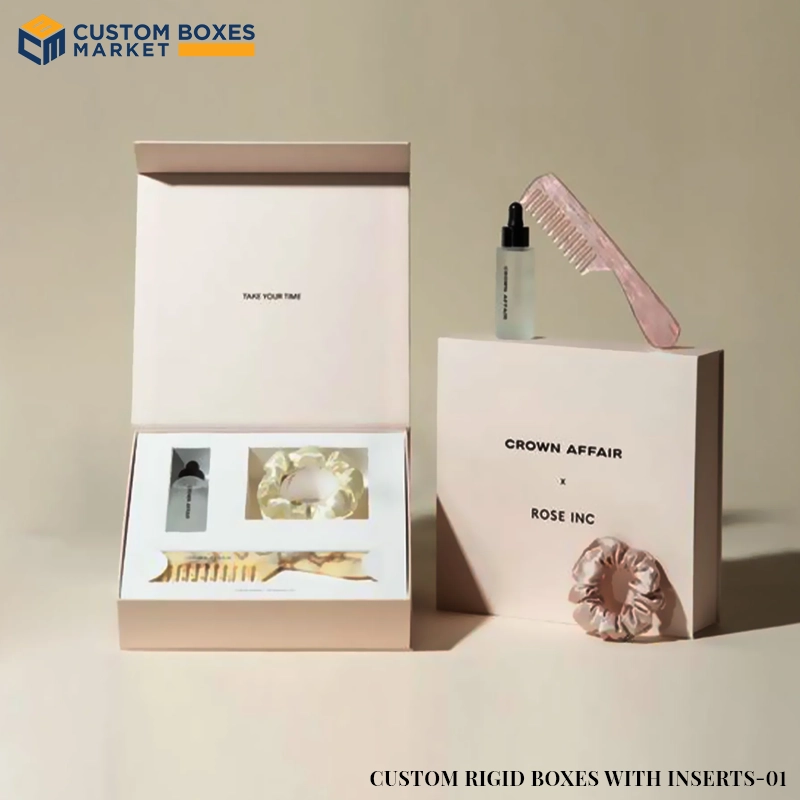

Taping and Types of Tapes Used for Rigid Boxes

Taping is essential to assemble rigid packaging boxes. We use double-sided tape as it gives clean assembly of edges without any visible adhesives. You can select the hot-melt tape option if you want to provide a strong assembly to heavy, custom unique shaped rigid boxes. Paper tape is chosen for eco-friendliness, and rigid boxes are used to retain the sustainable aspect of the packaging. Packing inserts are also attached to the boxes with tape to enhance the protective ability of custom rigid boxes with inserts. Your tape selection is a huge contributor to the overall strength and finish of the box.

Add-Ons

To give a premium look to the boxes, we have multiple add-on options. These options will dramatically increase the charm of your product and help you enhance the sales of your company. Custom magnetic boxes with handle or magnetic closures are one such example of this. You can get the following options of add-ons from us:

- Embossing and Debossing

- Foil Stamping

- Spot UV Coating

- Aqueous Coating

- Varnish and Lamination

- Magnetic closures

- Ribbons

Explore Our Range!

Put your hands on rigid packaging and present your product in the most premium manner. CustomBoxesMarket is giving the most affordable rates for all types of rigid boxes, so you can elevate the appearance of your product without a hitch. Call us now and grab the opportunity to explore our range.

Get Custom Quote

Frequently Asked Questions

You can invest in rigid boxes if you want to increase your sales by giving an elegant look to the products. These boxes help in increasing the perceived value of your products and make them more valuable.

We use thick paper to manufacture the boxes. This paper is cut and scored into the proper size and has a gsm of 800 usually. Chipboard is the main material used in these boxes. This material is compressed and layered into the required thickness to give a sturdy rigid material.

Corrugated boxes contain an inner fluted layer that increases the shock absorption properties of the boxes. In addition to this, these boxes are folded flat and can be easily reassembled. Rigid materials on the other hand are stiff, have a wood-like consistency and do not collapse.

Yes, you can get your boxes customized to the specific needs of your brand and give a personalized touch to your products.

Yes, you can use the boxes for various purposes because they do not get damaged easily.

At our company, we manufacture boxes with chipboard, a paper-based recycled material which is recyclable. However, the recyclability of the paper can be influenced by the applied coating and add-ons.

We send rigid boxes in a collapsible form to ensure a smooth shipping without any damage to the box shape. We have added adhesive strips or magnetic flaps to the boxes so that you can assemble them when required.

Yes! We give these smart features to give you packaging that is temperature-proof. Your customers will trust the authenticity of your product while accessing the product.

Yes! You can select soy and water-based inks to get sustainable options for your rigid boxes.

The standard time at our company is just 8 to 12 days, but you can consult our team to better understand the overall time based on your order.

To book a design consultation, contact us on the given email or phone number.

Related Categories

There is one just right for you!

BEAT MY QUOTE