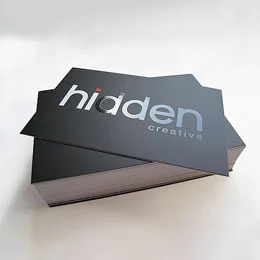

The Custom Boxes Market is one of the leading packaging industries that offers high-quality and unique custom boxes at an affordable price. From food packaging to the packaging of cosmetic products our company covers all domains. Our packaging not only keeps your product safe but also helps you in promoting your brand.

Tuck End Cover

Tuck End Cover

Get Custom Quote

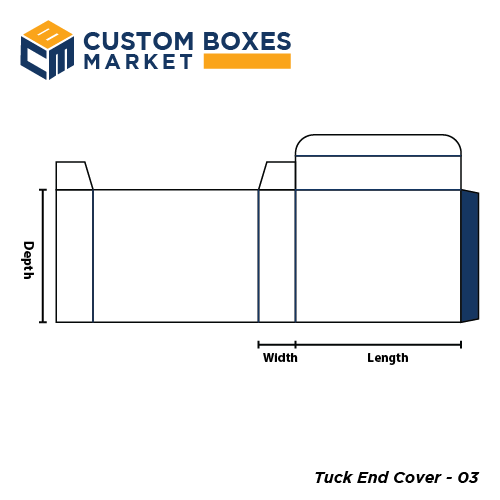

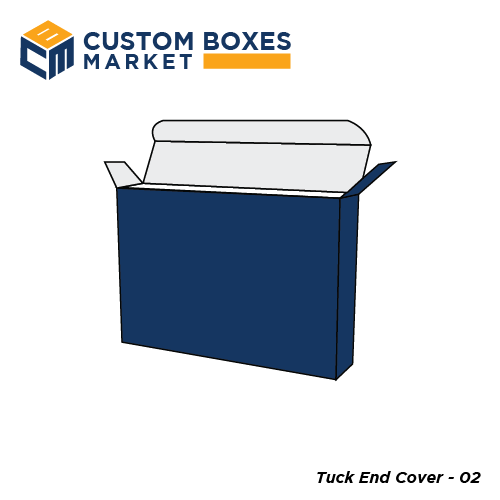

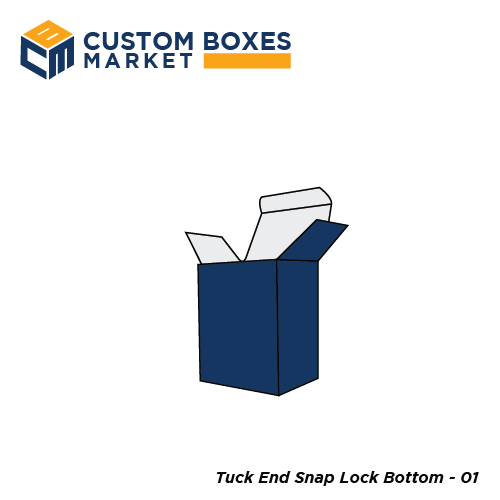

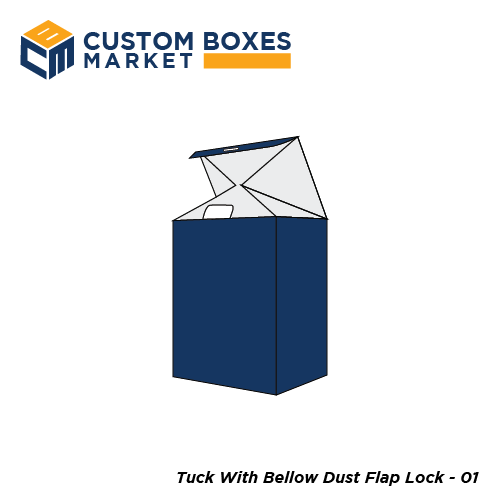

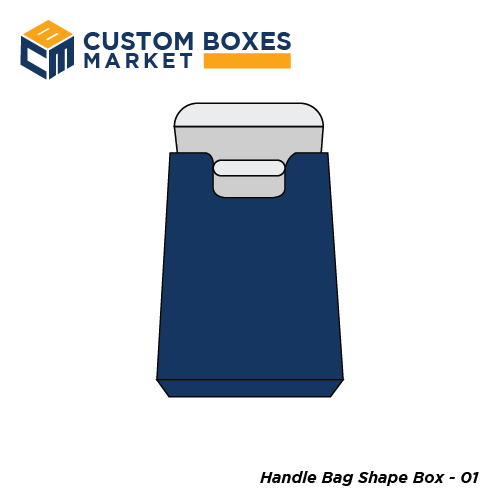

The Tuck End Cover is a practical packaging solution designed for durability and versatility. This box design is widely used for the packaging of various industries including food, electronics, retail, and cosmetics. This design has a tuck-in flap which slides or folds easily and provides the products with the needed protection.

Moreover, this style allows maximum flexibility and is particularly suitable for brands who seek to make their goods attractive and easy to use for clients. At CustomBoxesMarket, we provide all-in-one customization options as you can select from size, sustainable materials, high-quality printing, and finishings.

Tuck-In Flap System For Secure Closure

The top closure of the box features tuck-in flaps that provide ultimate security to the enclosed product. The flaps are designed on a button top and closure to securely close the packaging. These are some features of the top and bottom closure of the box:

Top Closure

The top closure consists of a tuck flap, dust flaps, and a locking mechanism which is customizable according to brand needs. These three components offer functionality and give a sleek appearance to your packaging style. Here are some main components of top closure:

Tuck Flap: The tuck flap is a single elongated flap hinged to the top edge of the front panel of the box. It is intended to close the inner part tightly and lock nicely in the body of the box.

Dust Flaps: These two flaps are extended at the top ends of the side panels. They are folded again to encapsulate the tuck flap, making it an added layer of cover.

Locking mechanism: The locking mechanisms in the design of the box include a slit or notch part of the sideways, which perfectly blends with the tuck flaps.

Types Of Tuck End Cover

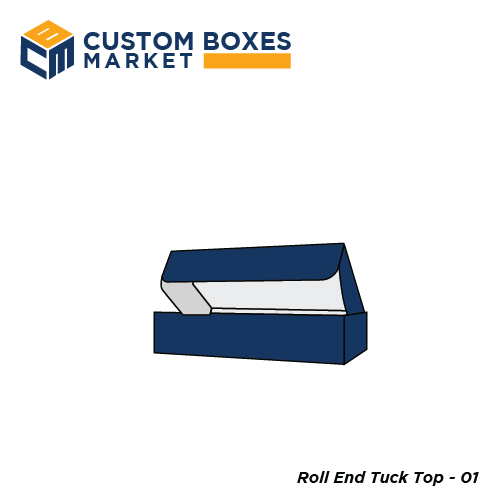

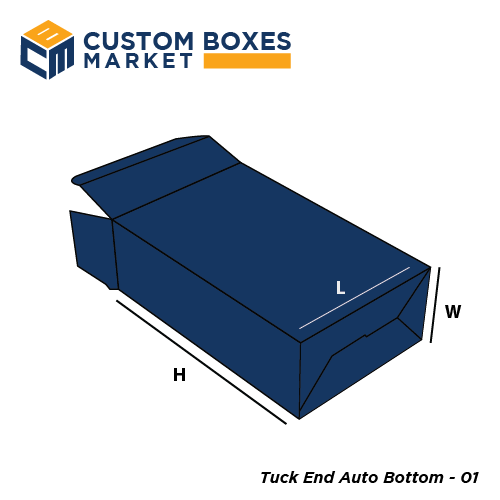

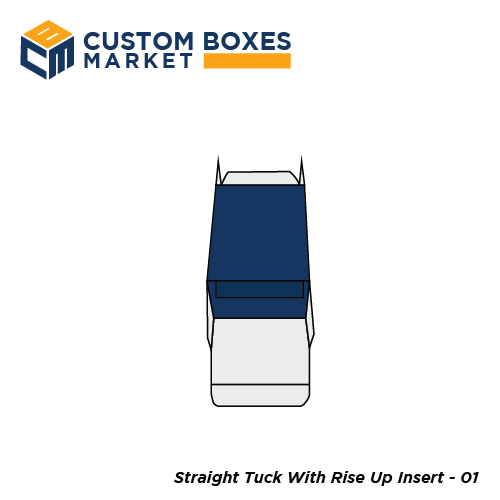

Tuck end covers come in many forms, creating different packaging options that cater to the packaging requirement without compromising on flexibility and security. Below are the main types of tuck-end covers:

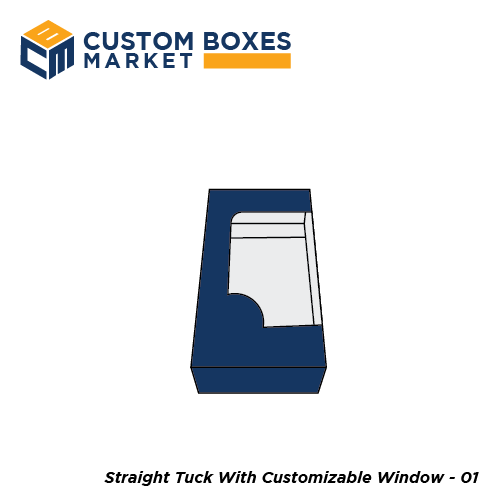

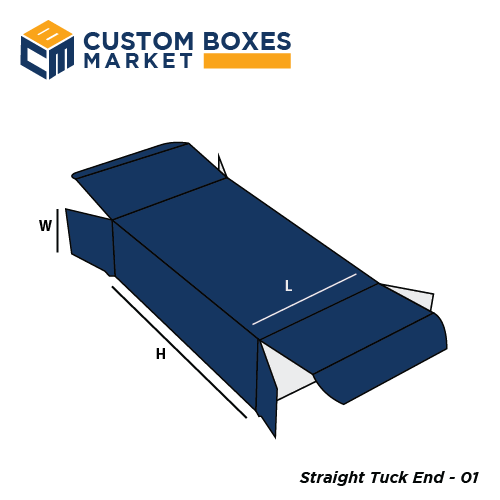

Straight Tuck End

The straight tuck end box has the top and the bottom flap folding in the same way and the same direction. Here the tuck flaps are fitted to the front panel to produce a clean and neat look. Some advantages of this box style are listed below:

- Sleek, professional appearance

- Efficient use of material

- Easy to assemble

- Customizable

- Space saving

- Tamper evident

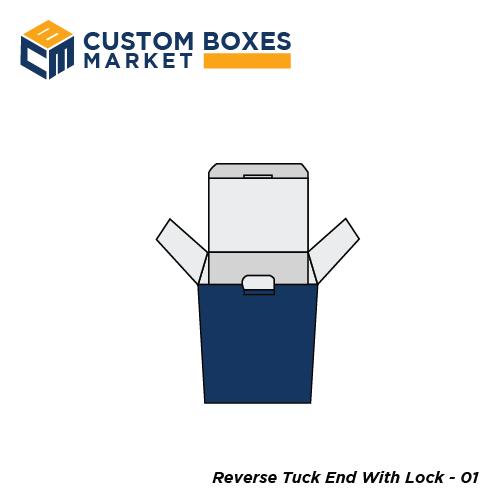

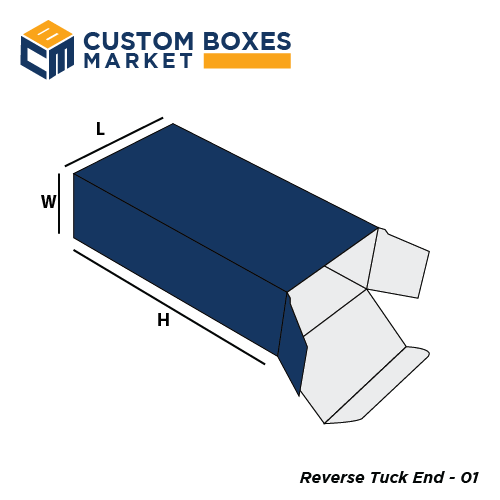

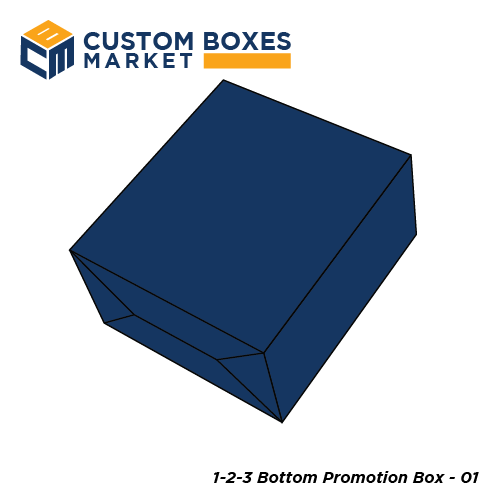

Reverse Tuck End

Here, one flap consists of the upper portion available to open or close in one particular direction and the other with the lower flap in the opposite direction. Here are some benefits of reverse tuck end boxes:

- Cost-effective manufacturing

- Easy assemble

- Secure closure

- Versatile design

- Improved structural strength

- Tamper evident

Eco-Friendly Manufacturing System

In our company, we follow eco-friendly practices in our manufacturing process intending to reduce environmental effects. Our target is not only to provide high-quality packaging but at the same time utilize efficient energy and minimize waste to the environment. For this, we have:

- Eco-Friendly Materials: Kraft, cardboard, corrugation

- Eco-friendly printings: soy and waters based inks

- Eco-friendly coatings: non-toxic and low in VOCs

Why CustomBoxesMarket Is The Right Choice

Our service offers bespoke packaging solutions that fit the needs of your product perfectly. If your product has its unique size, shape, or design, we give you the best solution to meet your needs. Here are some other benefits of choosing us for exceptional custom boxes:

- Fast turnaround time

- Competitive Pricing

- Innovative designs

- Customer-centric approach

- 100 MOQs

- Free delivery

- Free design help

|

|

||

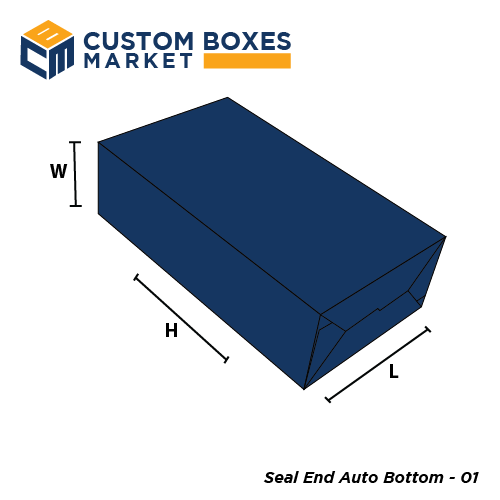

| Dimensions | All Custom Sizes & Shapes | ||

| Quantities | No Minimum Order Required | ||

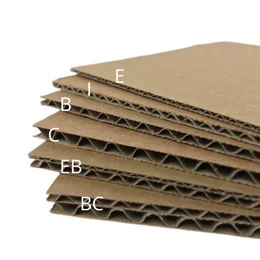

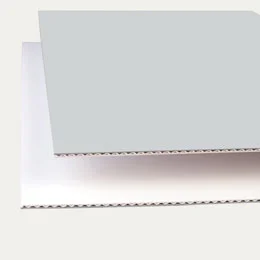

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock | ||

| Printing | No Printing, CMYK, CMYK + 1 PMS color, CMYK + 2 PMS colors | ||

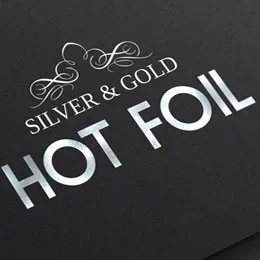

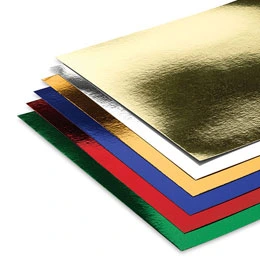

| Finishing | Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling | ||

| Included Options | Die Cutting, Gluing, Scored, Perforation | ||

| Additional Options | Eco-Friendly, Recycled Boxes, Biodegradable | ||

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) | ||

| Turnaround | 4 – 8 Business Days, RUSH | ||

| Shipping | FLAT |

Customer Review's

Our goal at CBM is to provide our customers with the highest quality custom boxes. Chat with us and let us know how we can help.

Do you have any queries about the customization of your boxes? Call us and get all your queries answered!

You may also like