A Complete Guideline Of Collate Printing | CBM

December 22, 2023 Packaging Stats

When it comes to printing there are many technicalities and technical terms that we have to encounter on a daily basis. Whether you are dealing with book printing or you are running a custom boxes company you have to deal with one term on a daily basis which is the term “collate”.

Although today the whole printing process is highly automated and there is little to no need for any manual intervention in the whole process nonetheless it is always better to get a basic understanding so that you can select the best thing for you. So let’s learn what collating is and what its impacts on the whole printing process.

What Does It Mean To Collate?

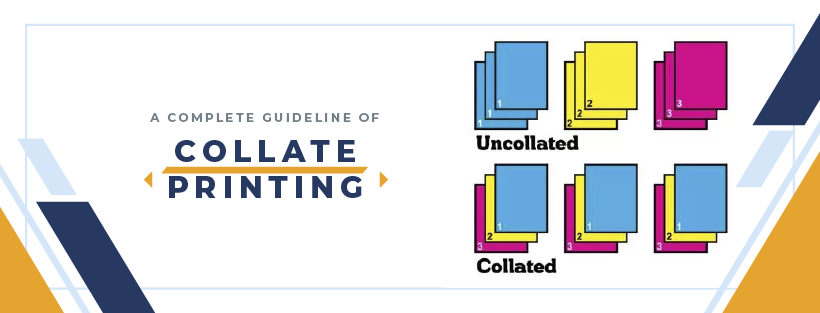

Simply put this term into words collate is a process in which multiple copies of a document are produced in a predefined order. Collation is derived from the term collection which means assembly. So in the collated printing process, an assembly of documents is printed in a specific order to get the fastest results.

Previously it took a lot of time to print documents as one has to set the printed substrate manually into the desired order. Apart from increasing the time of the printing process, the manual setting of the substrate leads to multiple errors. However, with the collation technique, these errors are eliminated to a significant extent.

When Does Collating Printing Help?

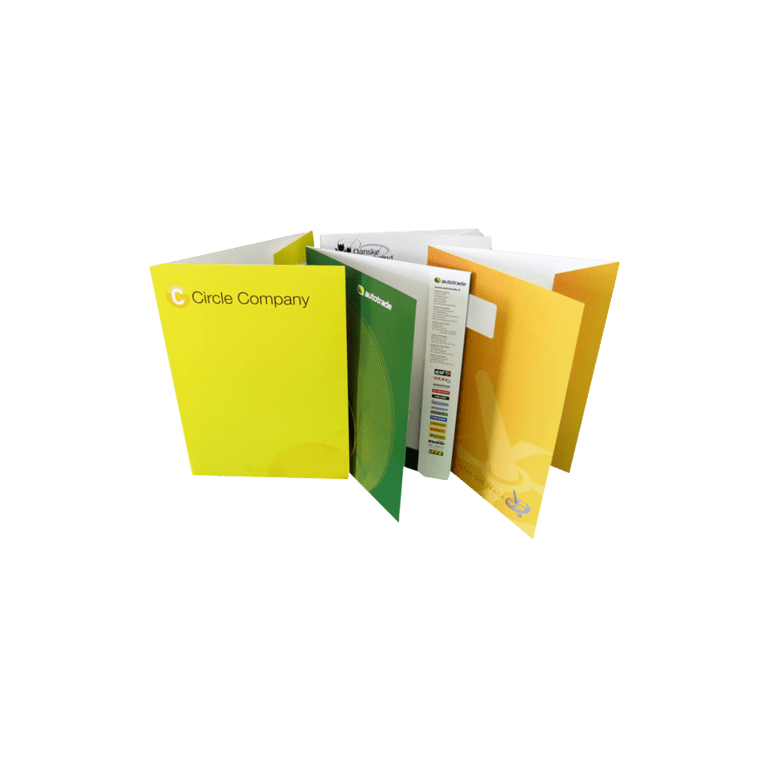

If you are dealing with printing books, magazines, custom boxes, or any paper substrate then you should use collate printing. You can easily and efficiently print all the documents, brochures, boxes, etc in bulk instantly.

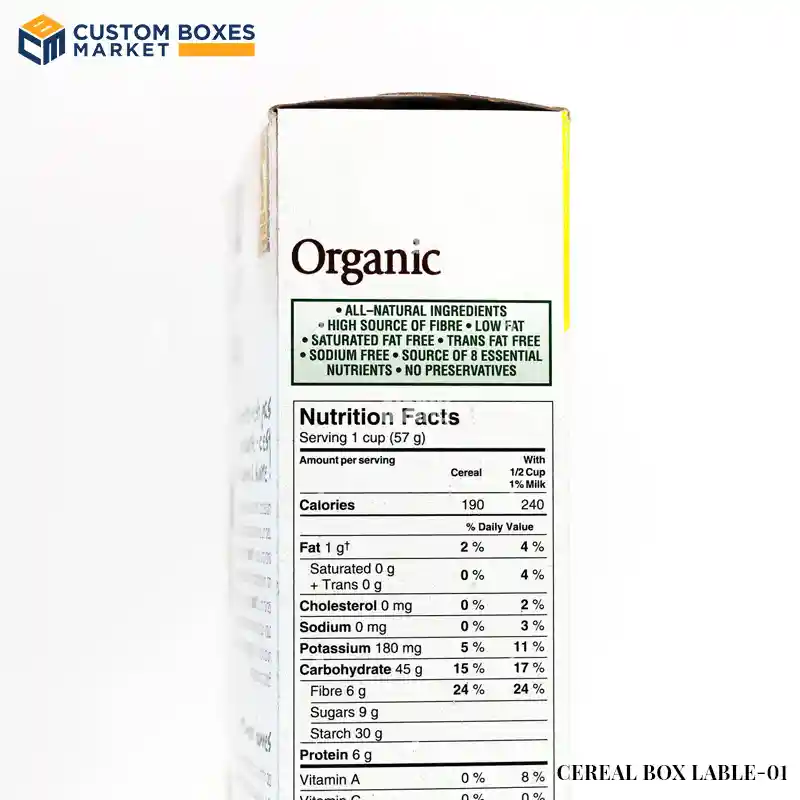

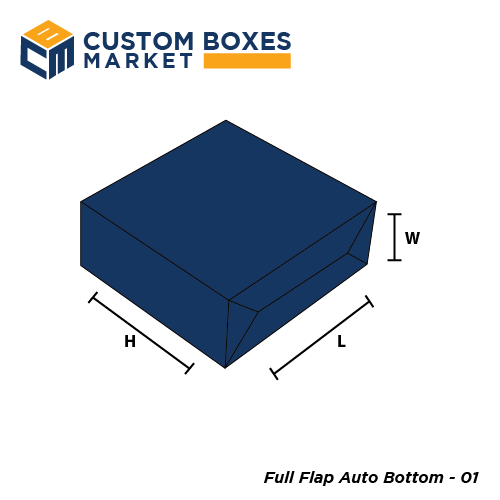

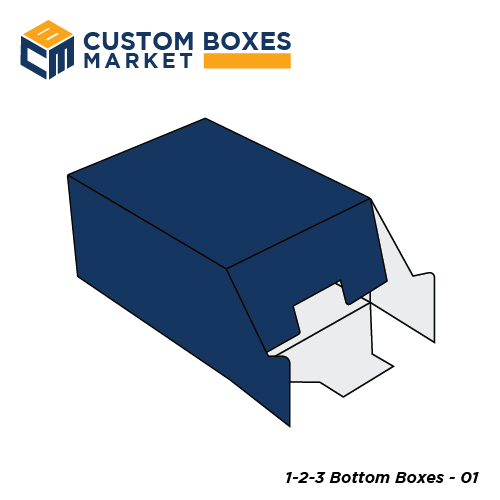

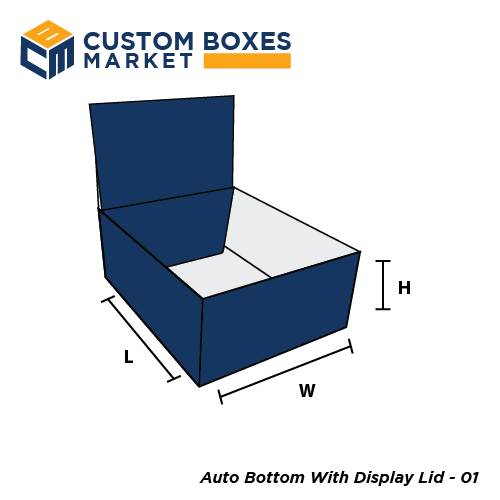

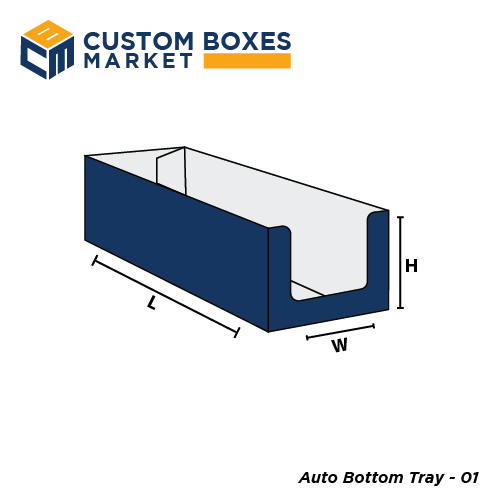

In the manufacturing of custom boxes like food packaging, display boxes, etc the utilization of collation gives multiple copies of the printed same or different stock at the same time. The multiple copies of a multipage document will be attained easily and without the investment of a lot of money and time.

In the past when this collation process was not invented printers had to take a lot of time to print copies of a multi-page document. This not only requires a lot of time but also increases the cost of printed items making it difficult for small businesses to choose a multi page and multi-design document. However, with collate printing innovation in designs has become extensively accessible to all.

How Does Collation Work?

In the clients’ operating system, there is software for collation. You can go to the print setting and open the dialogue box to find the option of collate printing and start your printing.

In collation, the substrate, such as paper, is loaded and the collation process arranges the pages, assembles them into a desired order as commanded, and prints the multipage document simultaneously.

The absence of this process requires mass printing of documents page by page. Today everyone wants convenience so the preference for processes that take the least time and minimum investment is desired by everyone.

Say a publisher needs a novel and wants to get the edition in minimum duration with precision. This is because the reader has to flip the pages and read the rest of the story in chronological order. In this case, the use of collate printing becomes crucial to avoid any error in the printing of pages.

Types of collate printing

To facilitate the users the process of collation is available in two forms namely manual and automated collation. Both processes are almost alike except for one thing which is that specialized stock is required to be filled differently. Below are its two different types:

-

Manual Collation

In manual collate printing manual filling of stock is required to be filled for different stocks. Although this process gives the same results as that of automated collation, notwithstanding here a little more effort and time is required.

-

Automatic Collation

In automatic coalition printing, front-end software is present. This software commands the system to pull the required printed substrate from different stock. Automatic collation is a rapid process as compared to manual one and has little to no chances of human error.

What Is The Difference Between Collated And Uncollated Prints

In the collate printing process there is no need to manually adjust the separate run for different stocks you just have to command the system to print the copies in a predetermined order. When the first round of copies or the first printed documents is complete, the second copy automatically starts to print till the number of commanded copies is produced.

On the other hand, in an uncollated printing process, you can only print a stack of the same type of documents. This means that you cannot print the paper in sequential order. Each stack of printed paper will be the same. This process makes it difficult when different stocks at the same time in a desired sequence is needed.

Advantages Of Collate Printing

The collation process has made it easy for publishers, custom box manufacturers, and any business that involves the printing process to get multiple copies of a printed substrate in a minimum duration. Some of the advantages of collate printing are as follows:

Inexpensive

The whole process is inexpensive so even small companies can get the benefit of this advanced technique. The cost effectiveness of this method is because fewer steps are involved which requires less tooling and little manual labor.

Improved Quality

Collation gives accurate results and high quality. As there is the least requirement for human intervention there are fewer chances of any error. Highly accurate and premium quality in the exact required order can be produced instantly.

Fast

Collate printing is a fast process. Again the absence of human intervention is the main reason for this. Furthermore, automated collation significantly enhances the processing speed and hence the hassle of changing stock every single time.

Common Uses Of Collate Printing

Collation is a common process that can be used in diverse setups and industries such as:

Report Printing: In report printings collect order of printing is required which is why collate printing is used.

Presentation Making: Collation is used in the printing of slides where the intended order is printed simultaneously in multiple copies.

Manual Or Guideline: In manual guidelines, it is necessary to print the documents in chronological order to give logical understanding to the readers.

Billing Books: Billing books are printed with collation due keep the customer information correct.

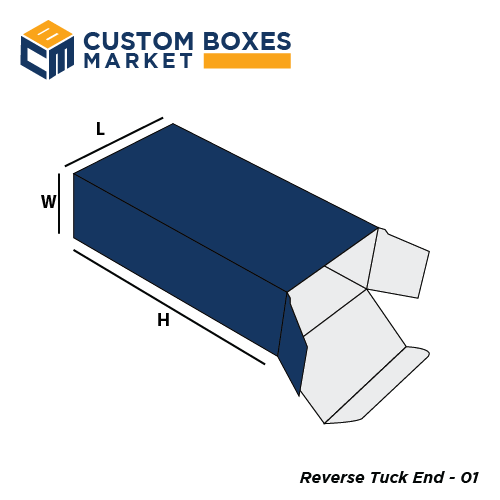

Custom Boxes: In custom boxes, like cardboard boxes, retail boxes, etc the process of collate printing is used as here multiple copies of a desired box are printed simultaneously.

FAQ’s

- Are there any benefits to using automatic collation?

Yes, automatic collation reduces the time, effort, and error in the printing process.

- Can we use collation with any type of printing job?

It is required when a specific stock in a specific order is required to print.

- What does collate mean when printing something?

Collate means printing a collection of stock in a specified order.

- What does collate mean when printing double-sided?

The term will remain the same even if it is done on double sides.

- What happens if I don’t collate?

Collate printing is not a default process and you have to give the command to your printer to include this process, so if you don’t want it you can skip this process. Nonetheless, the elimination of collation will make your printing process slightly complicated, and long, and will demand some extra cost.

- Can we use collation for single and double-sided printing?

Yes, it can be done both ways.

Categories

Recent Posts

4 / March , 2026 Packaging Design

19 / February , 2026 Box Customization

16 / February , 2026 Box Material

3 / February , 2026 Gift Boxes

26 / January , 2026 Gift Boxes

6 / January , 2026 Sustainable Packaging

3 / December , 2025 Packaging Stats

17 / November , 2025 Custom Packaging

14 / November , 2025 Product By Industry

4 / November , 2025 Shipping Protection

28 / October , 2025 Custom Packaging

9 / October , 2025 Custom Packaging

7 / October , 2025 Shipping Protection

Get Free Quote

Related Products