What is Die Cutting? What Does Die Cut Mean in the Die Cutting Process

June 6, 2024 Box Customization

When it comes to cutting any material, whether it is paper, plastic, or any metallic substance the process of die cutting is used. This process is quite crucial for the precise cutting of the material and to minimize waste generation.

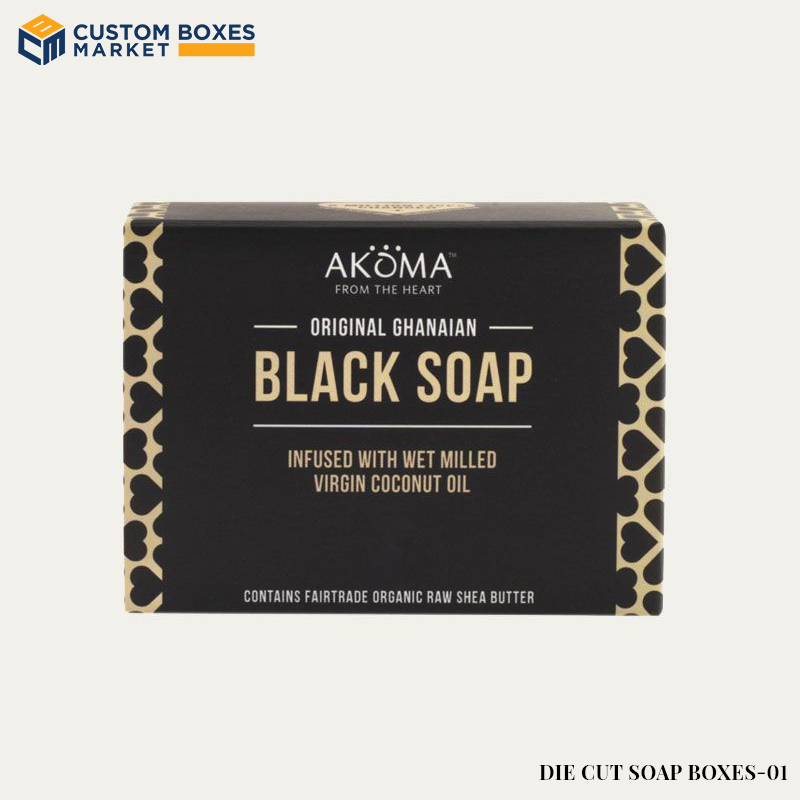

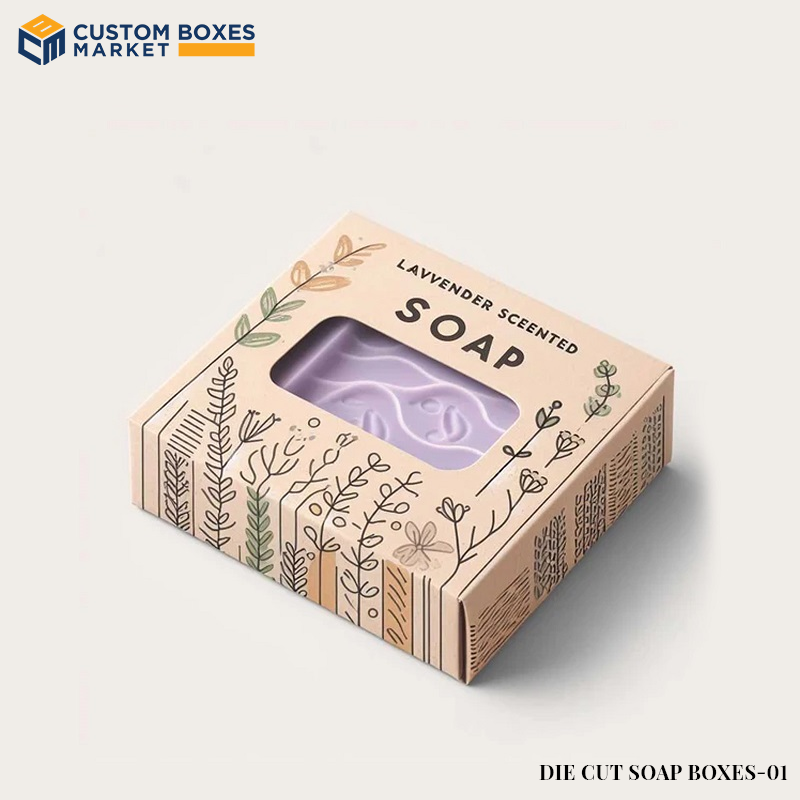

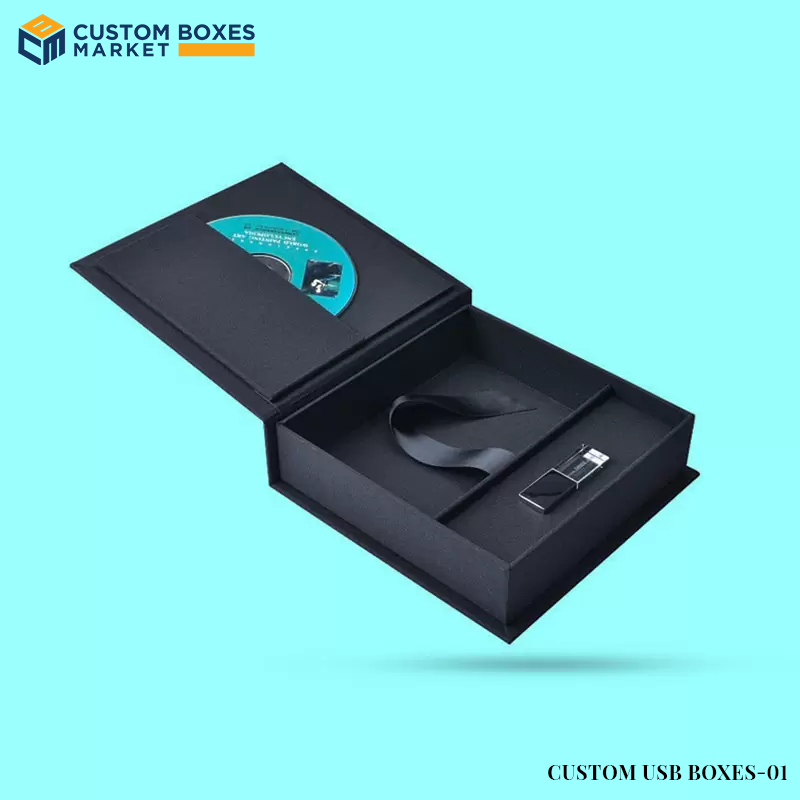

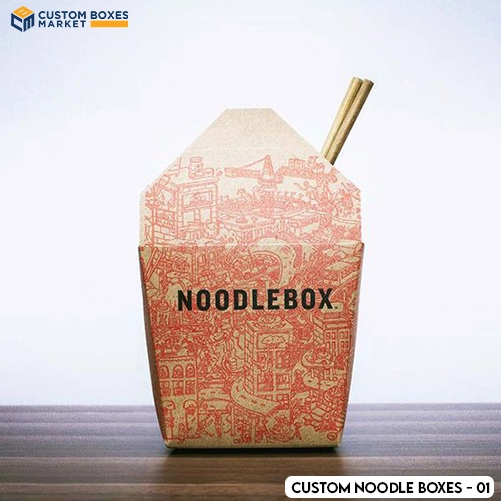

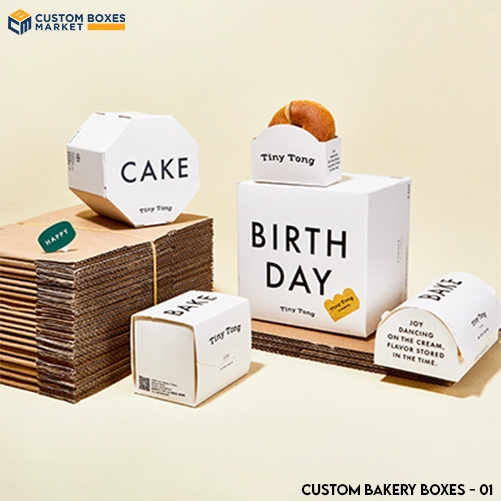

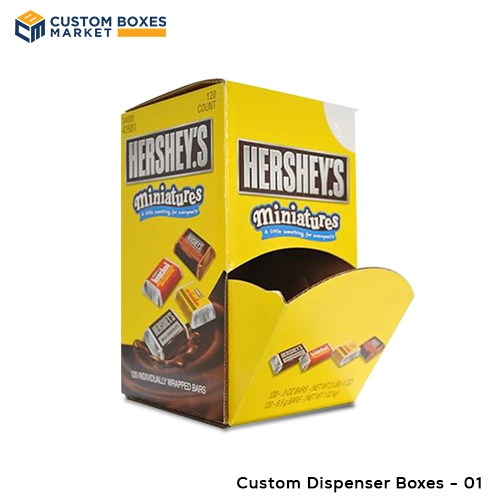

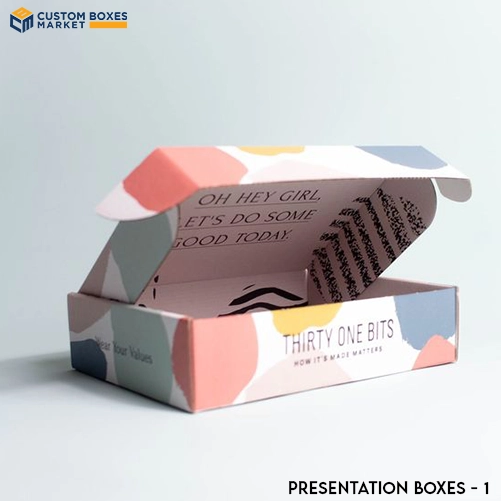

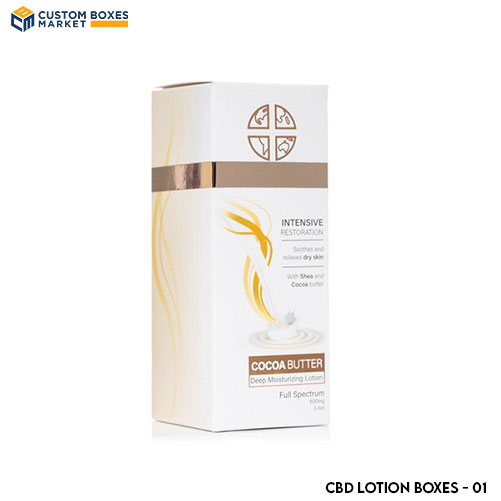

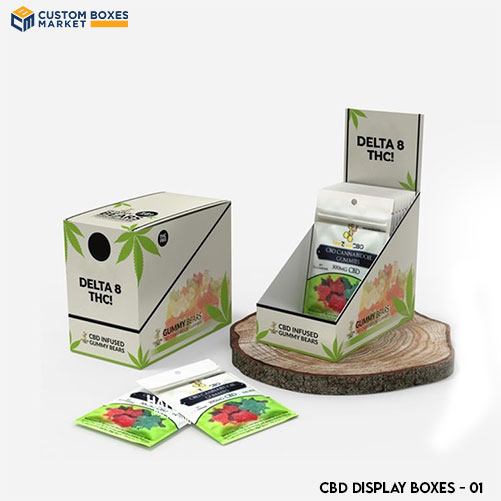

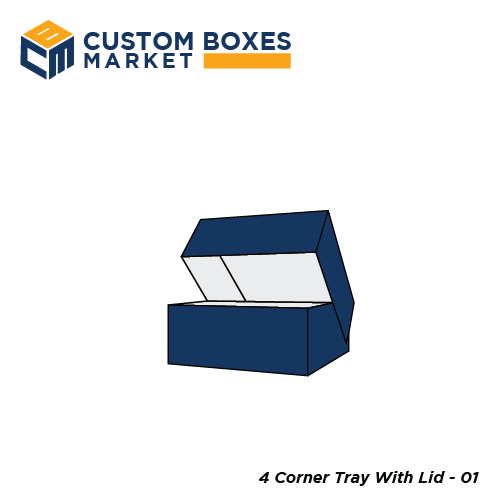

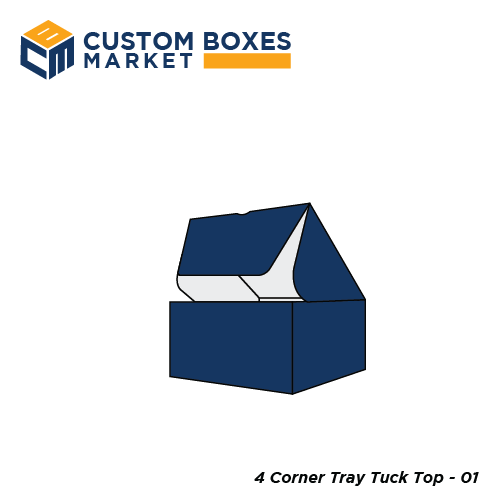

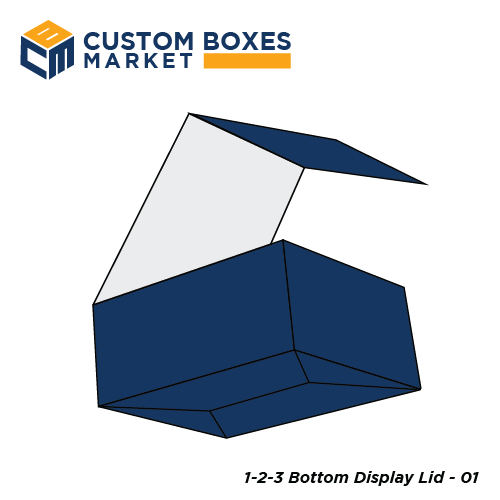

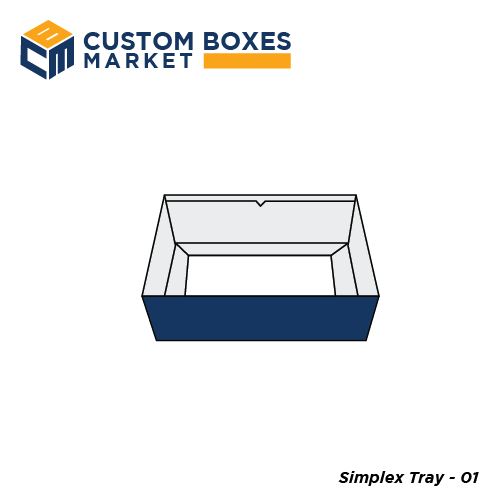

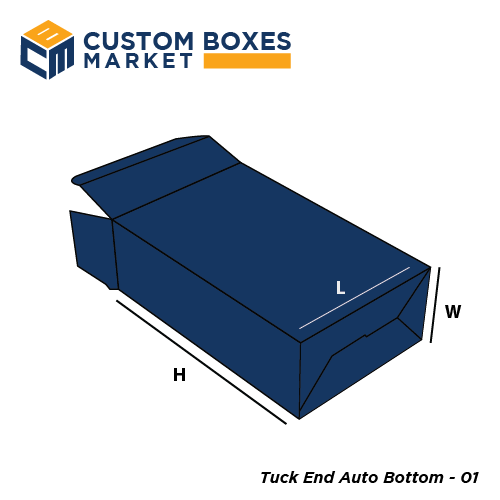

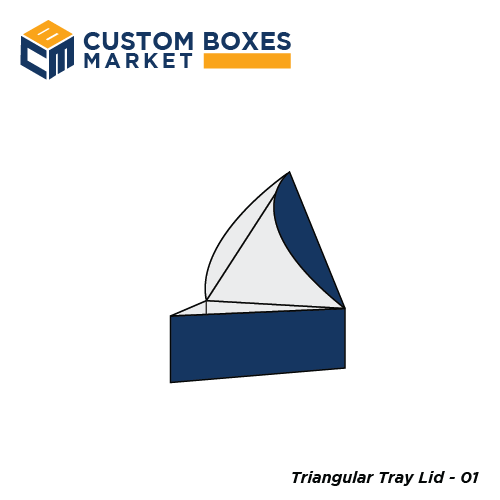

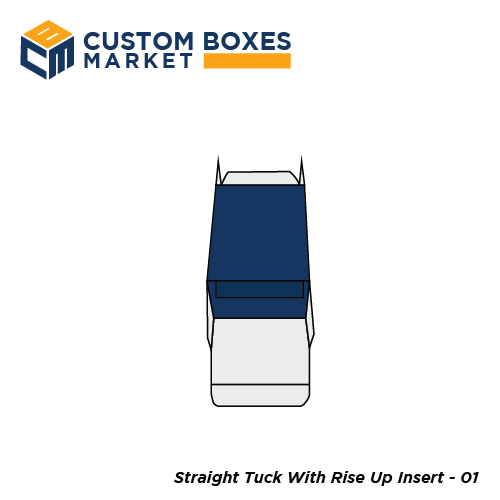

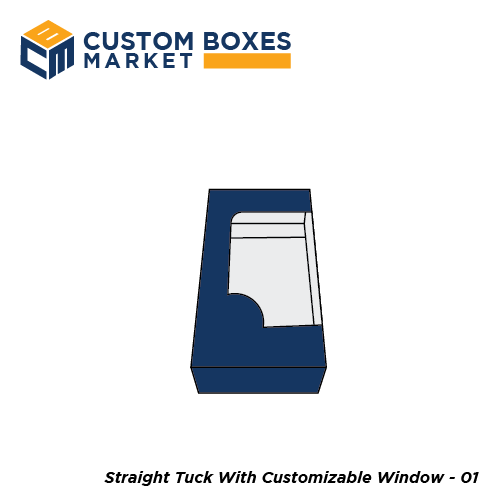

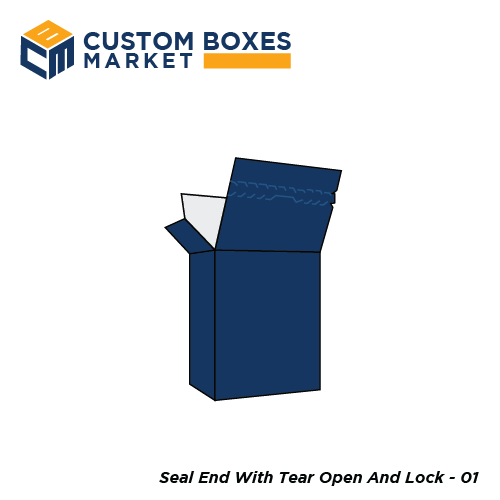

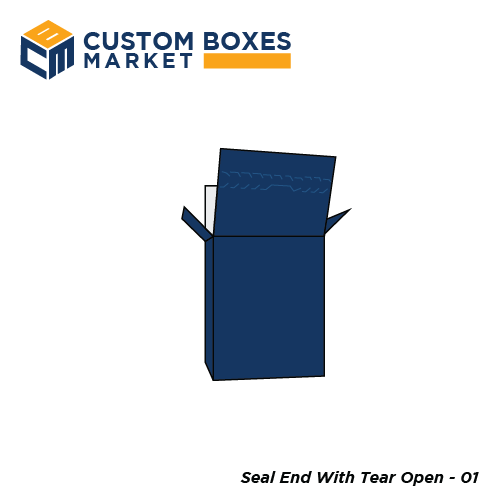

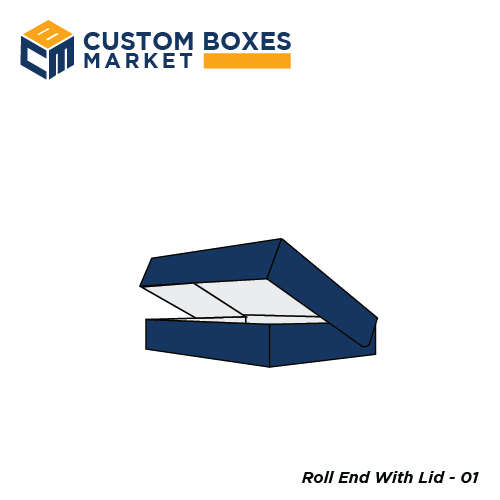

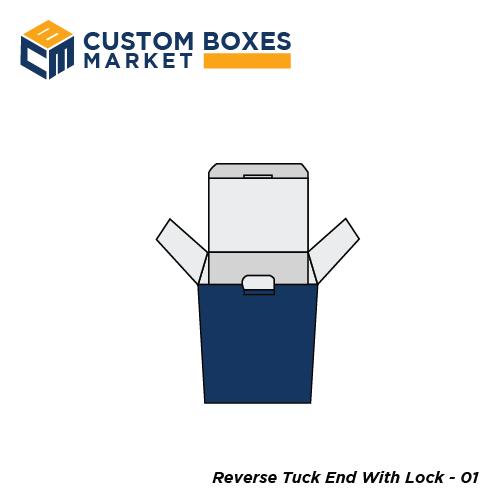

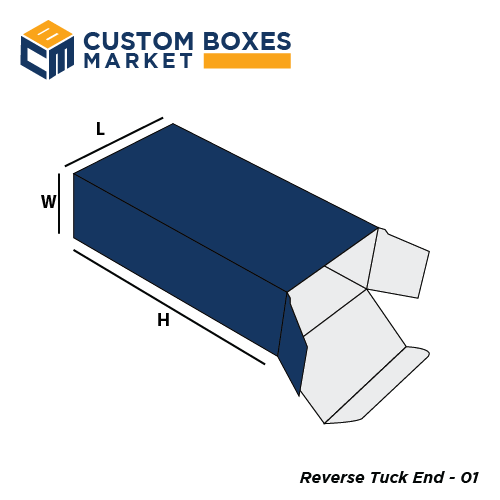

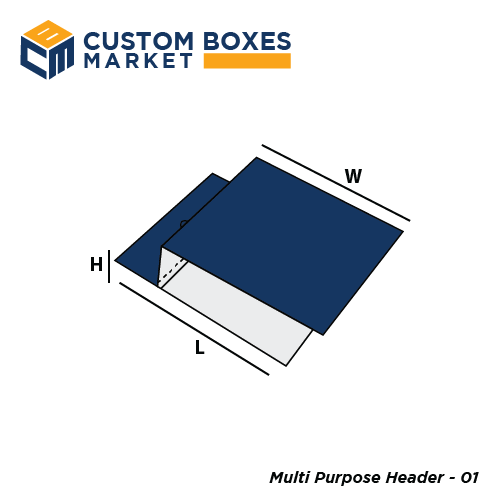

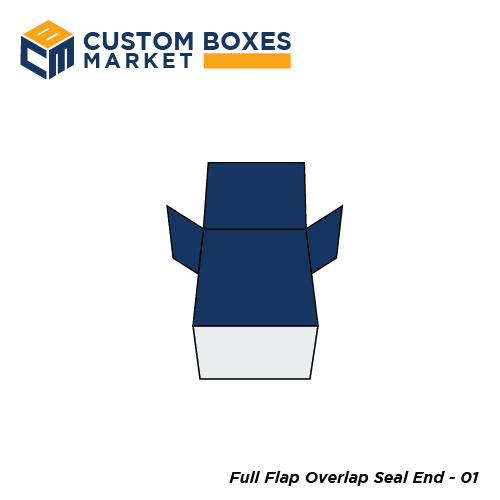

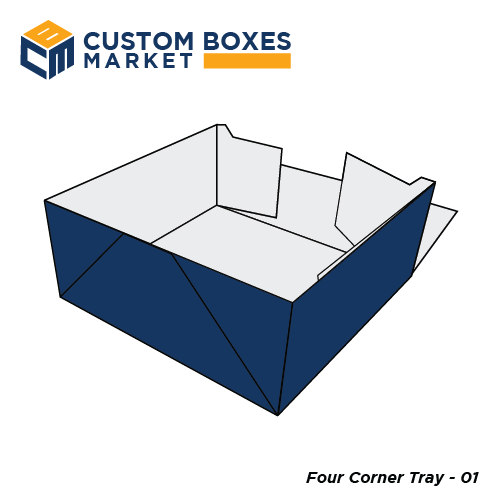

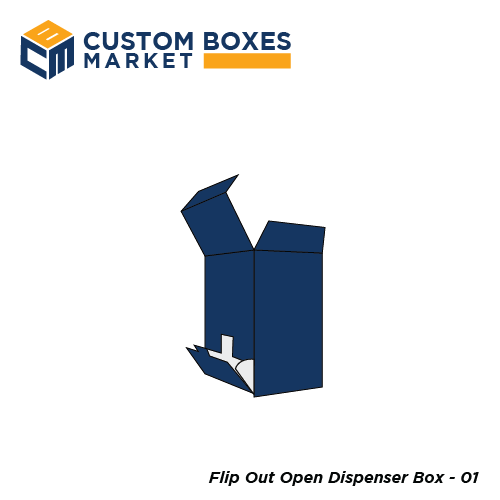

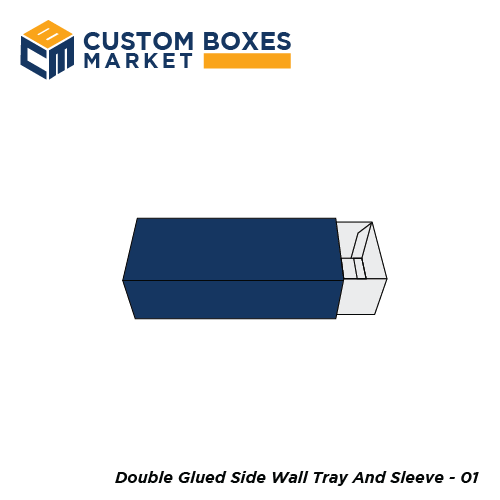

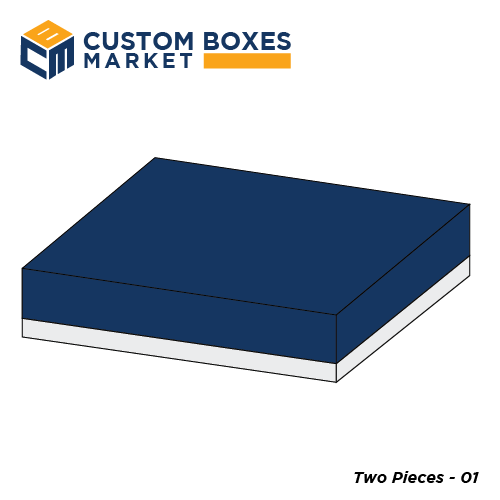

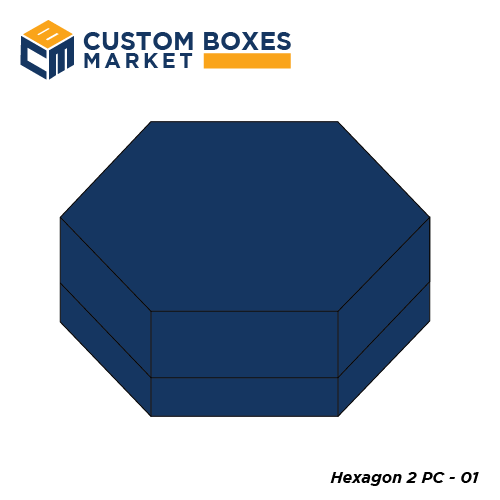

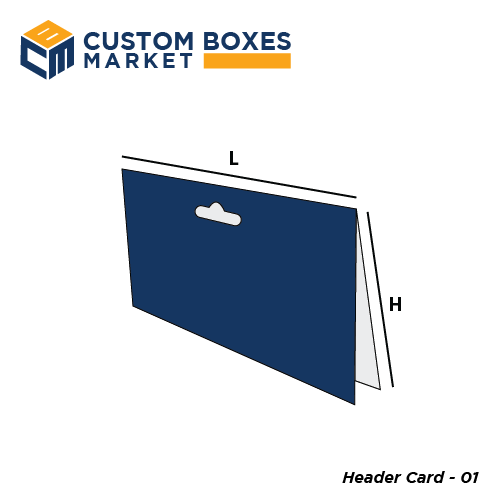

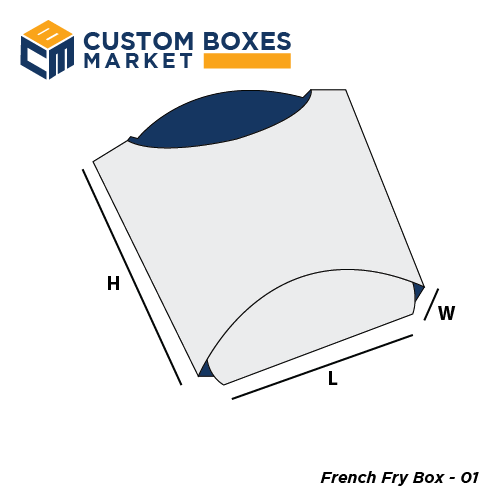

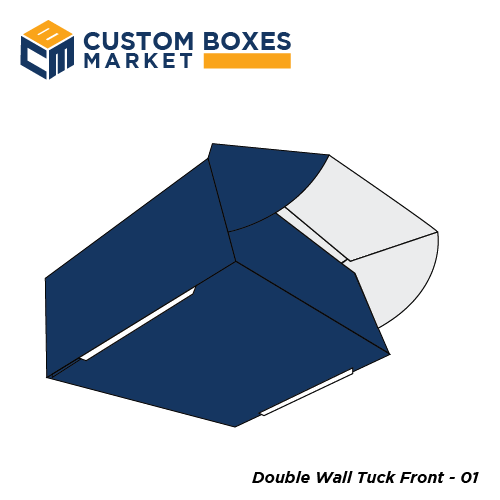

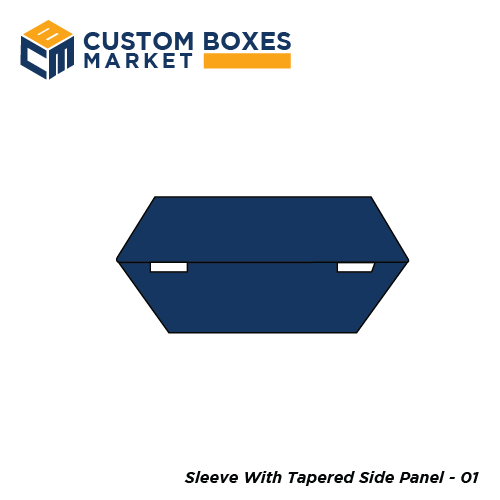

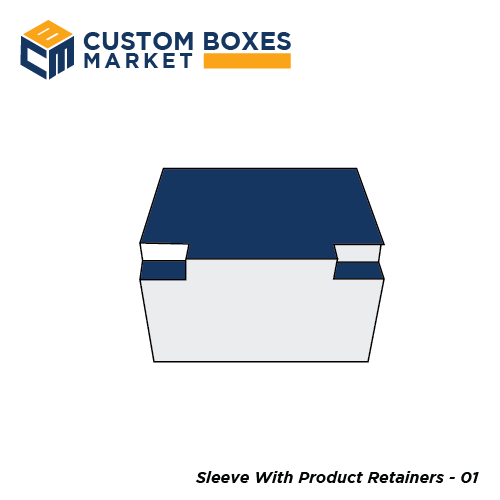

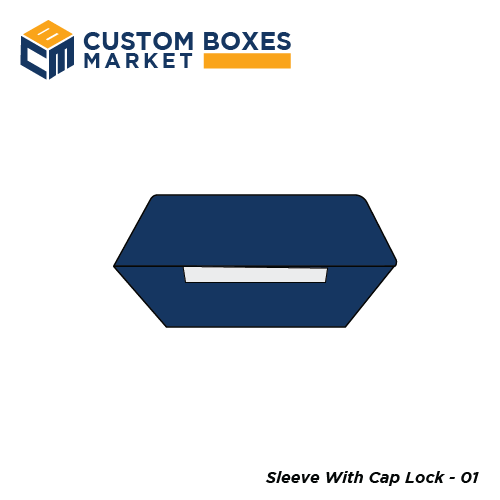

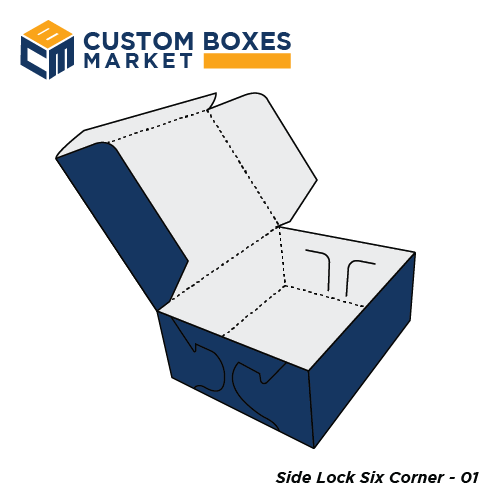

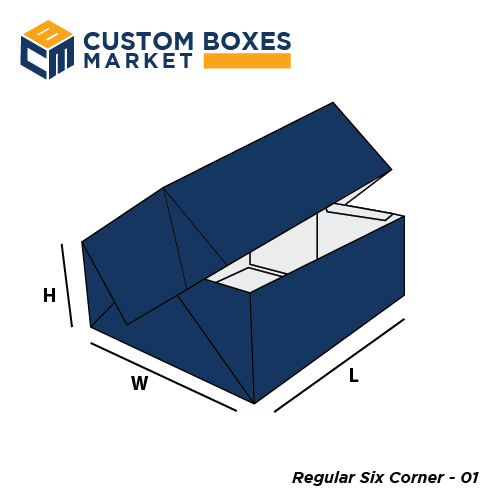

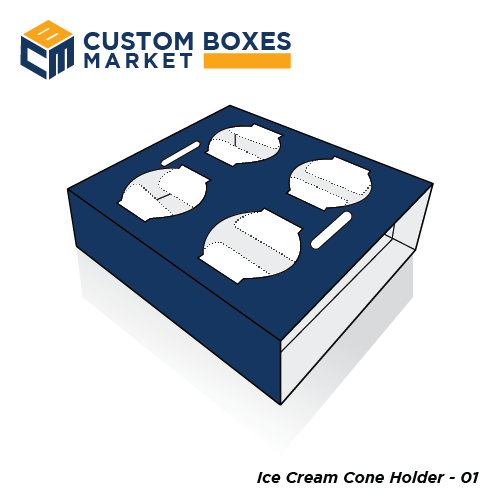

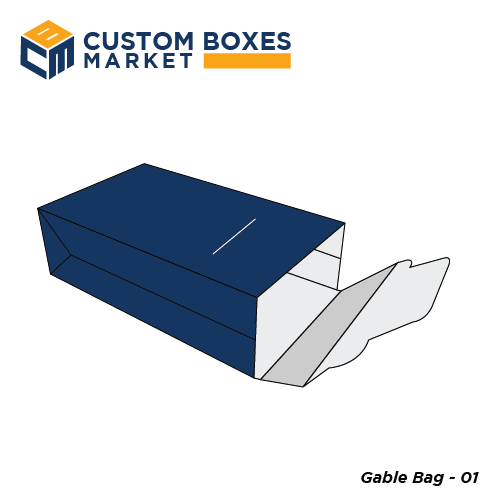

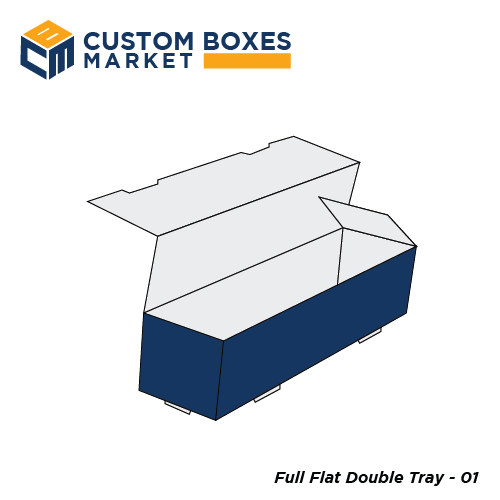

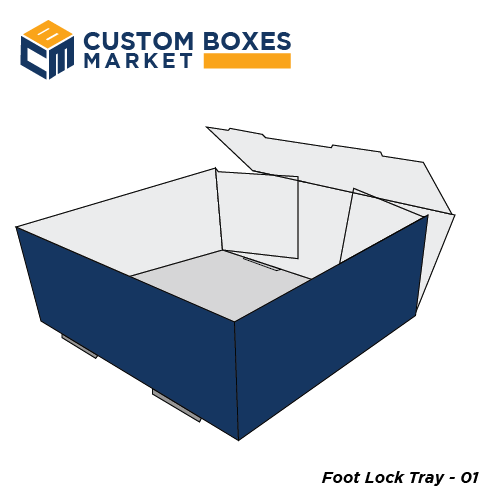

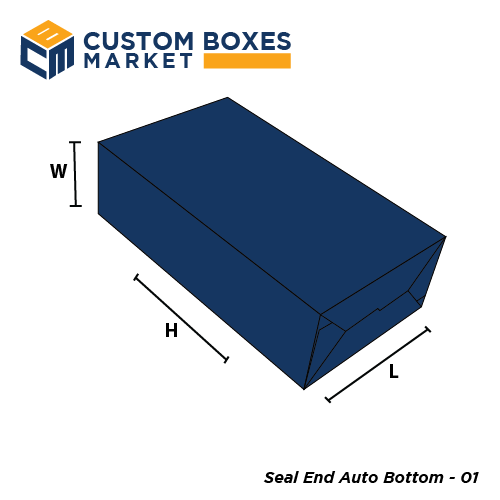

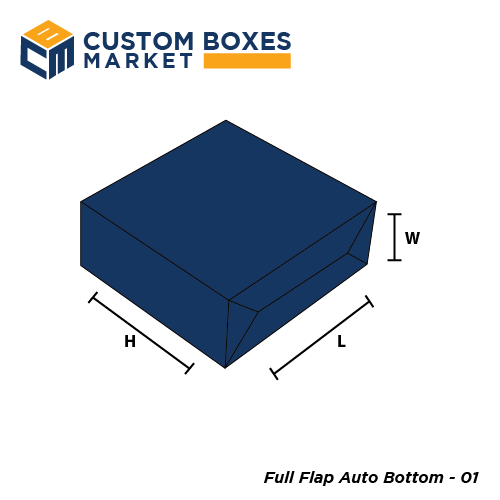

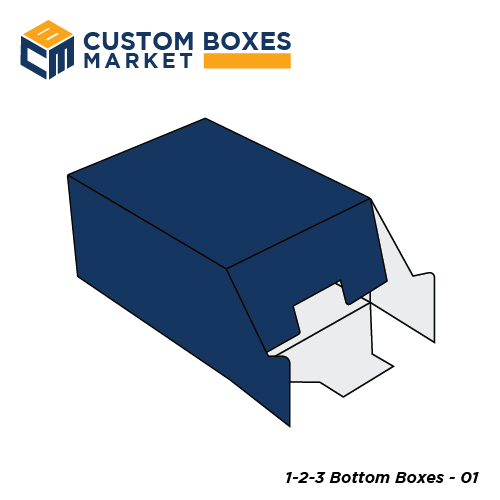

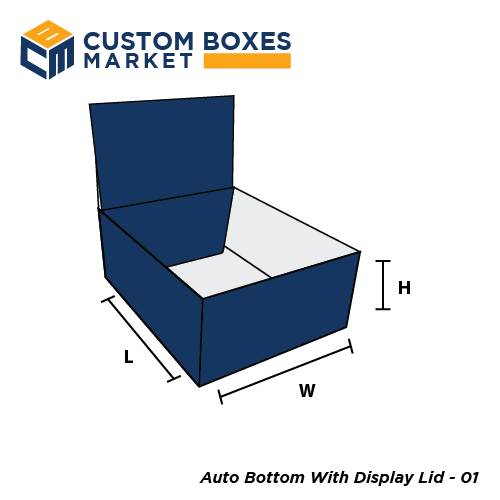

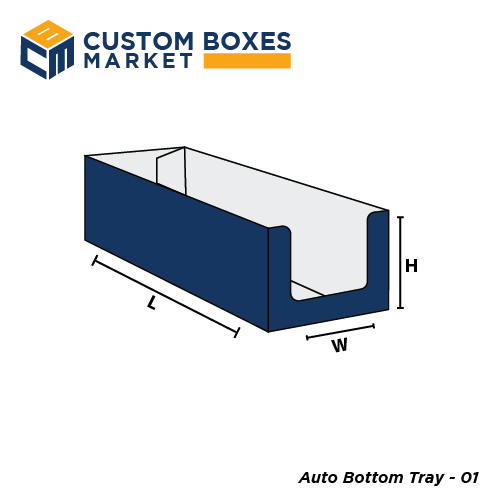

Specifically in the custom boxes market, innovative die-cutting processes have made it easy to produce unique styles and various sizes of boxes. Now brands prefer different styles and shapes of their boxes, custom labels, etc so that they can maintain their uniqueness in the market.

Although the process of die cutting is a task that must be left to the professionals, you can get a basic idea of what is die cutting by reading this blog which will help you make an informed decision about the design of your custom boxes.

What Does Die Cut Mean in the Die Cut Process?

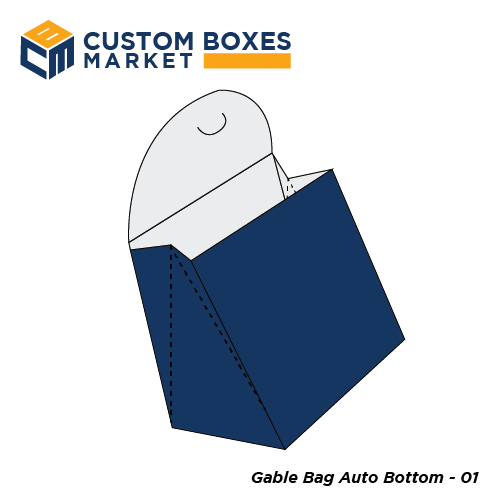

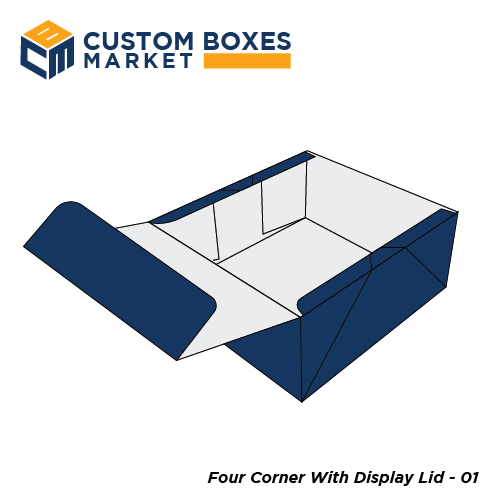

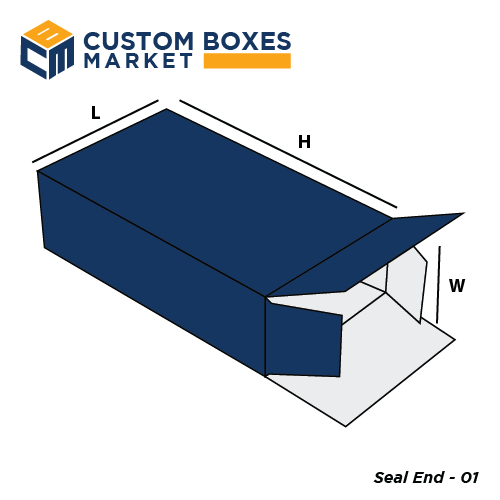

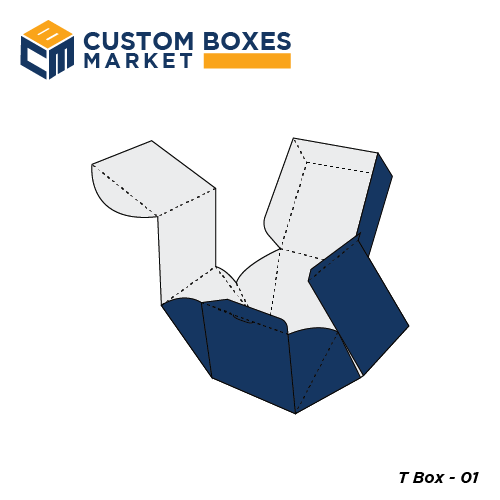

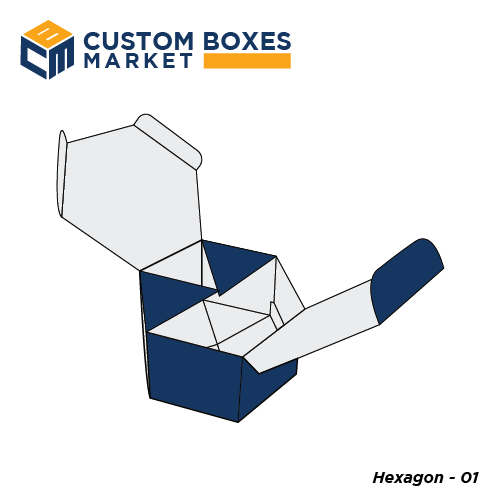

In simple words can say that die cutting is a process in which a template is created for the product we are going to manufacture, in the packaging sector, this process is used to cut different shapes of boxes with precision and exact measurements to get die cut pieces of the material.

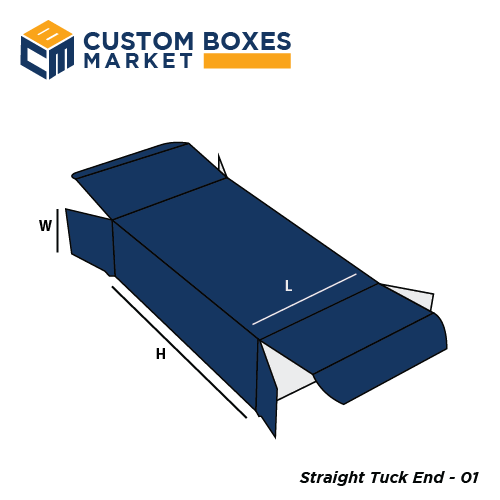

When it comes to box manufacturing one must keep the box dimensions precise so that neither you can a wrong-sized box nor you have to waste your raw material. There are multiple types of die cutting processes that are mainly selected based on the budget and the type of material.

What Is Die?

A die is a kind of cutter that is used in the die cutting process. It has variable shapes depending on the box style. A specialized and sharp tool made from metal is used to cut through the paper such as a paper board. There are different types of dies some are used to cut a sturdy or a bit thick material and others are used to cut thin material such as:

- Steel rule dies

- Metal dies

In steel rule die, plastic or foam is used for the sake of protection, however in metal dies these protections are not required. Thin metal dies are also easy to store and lighter in weight. There are multiple types of die cutting such as:

- Blanking: Here the material is clipped from the edges

- Drawing: It passes the material from the die-cutting machine to get a specific length of the material

- Forming: It is a good option for cylindrical packaging as a curved surface is used to shape the material

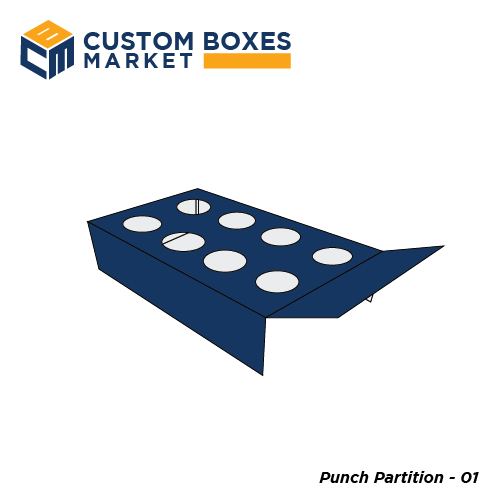

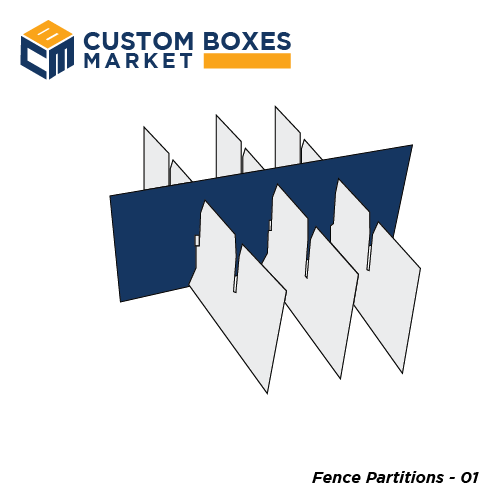

- Coining: In it, holes are created in the packaging by the application of pressure. If you need punch partitions in your boxes then this is a good option

- Broaching: In this method, multiple teeth are used along with the dies. These teeth pierce the material multiple times to make it easy to cut via a die. For custom rigid packaging, this method can be considered

Role Of Die Line In Die Cutting?

A die line is a template of the shape that one has to cut with the die-cutting machines. This die line can either be designed manually or via designing software for precision. It is done before finishing the boxes. There are different components of the die line such as:

- Bleed line

- Fold line

- Cut lines

- Safety line

- Trim line

- Glue tabs

What Are Die Cutting Pads Or Plates?

Die-cutting pads or plates are the components of die-cutting machines that are used to align all the components of the process for perfect cutting. These plates create a kind of sandwich of material, die, and other components of the machine so that appropriate pressure can be applied to the material.

The machine pushes the plates, which are available in different sizes and shapes, onto the die and applies pressure due to which the die cuts down the material into the desired design or die line. You have to replace the plates over time.

Types Of Die Cutting Machines

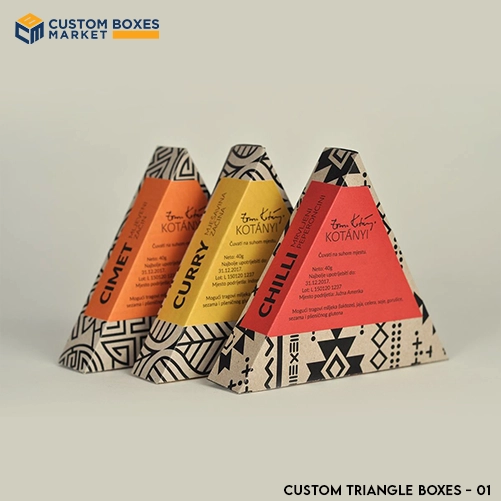

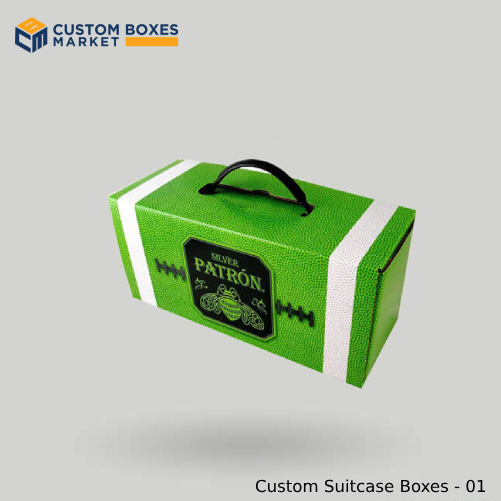

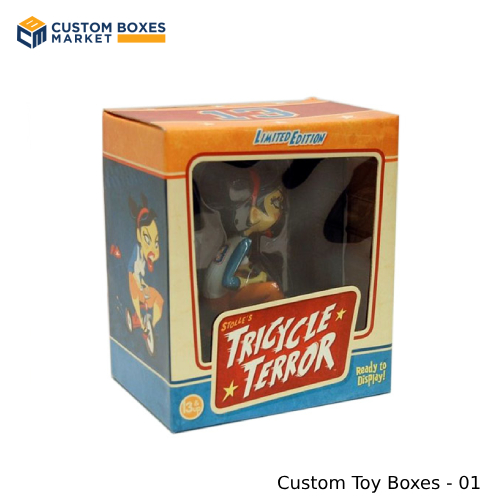

Die cutting is one of the crucial components of custom packaging boxes. No matter how complicated the shape of the box you are looking for, with the advancement in the die cutting machines unique shapes and sizes of packaging can be produced such as pyramid boxes, triangle boxes, round boxes, etc. Depending on the type of material, the budget of the company, and the extent of precision there are three types of die-cutting machines:

- Manual Die Cutting: As the name indicates, this process is handled manually and is a good option for smaller runs of packaging or labels. This machine is portable and may also have a crank or lever to assist in pressure application.

- Digital Die-Cutting: This machine is digitally controlled and has made it easy to create intricate designs and styles of boxes. It is much more precise than manual machines and is mostly used at the business level.

- Industrial Die Cutting: An industrial die-cutting machine is a heavy-duty machine that is also controlled digitally. With this machine heavy-duty material in any shape can be obtained. In the custom packaging industry, this machine is a preferred option.

Process Of Die Cutting

The process of die-cutting is not as complex as it seems to and it depends mainly on the type of material and the complexity of your design. This process is divided into design creation, die-making, material preparation, cutting, and finishing.

- Design Creation: A graphic designer creates a design or die line of the box

- Die Making: As we know this is a sheet of metal with cutting edges according to the die line

- Material Preparation: Material is placed on the die-cutting machine with the perfect alignment to the machine

- Cutting: Pressure is applied on the material to cut it down

- Finishing: If a customer opts for additional designing then we can score, emboss, deboss, crease the material

Die Cutting And Printing

Most of the time a question comes to mind as to whether one should do die cutting before the printing process or after it. This selection is mainly based on the shape and number of the end product.

Benefits Of Using Die Cutting Before Printing

If you want an exact shape and size of material with the precise alignment of the design then it is a good option. Die cutting before printing will help to handle intricate designs and irregular shapes easily. Not only this you can manage the position of your material as compared to pre-cut pieces.

Benefits Of Die Cutting After Printing

When you die cut your material after printing then you get a bit flexibility of in your design. The printed design extends on the edges of the material and gives a full bleed printing. This makes the handling of smaller pre-cut pieces easier as you can easily print on a large sheet.

Choosing What Is Good

Whether you should die cut your material before printing or after printing? This depends upon various factors. While choosing the die cutting process you have to keep in mind the following factors:

- Design complexity, when the design must align with the cuts then printing after die-cutting is a good option

- If handling smaller materials is challenging for you then you can print the material after die-cutting

- Delicate material should also be cut before printing

- For high volumes and more efficiency printing before die-cutting is better

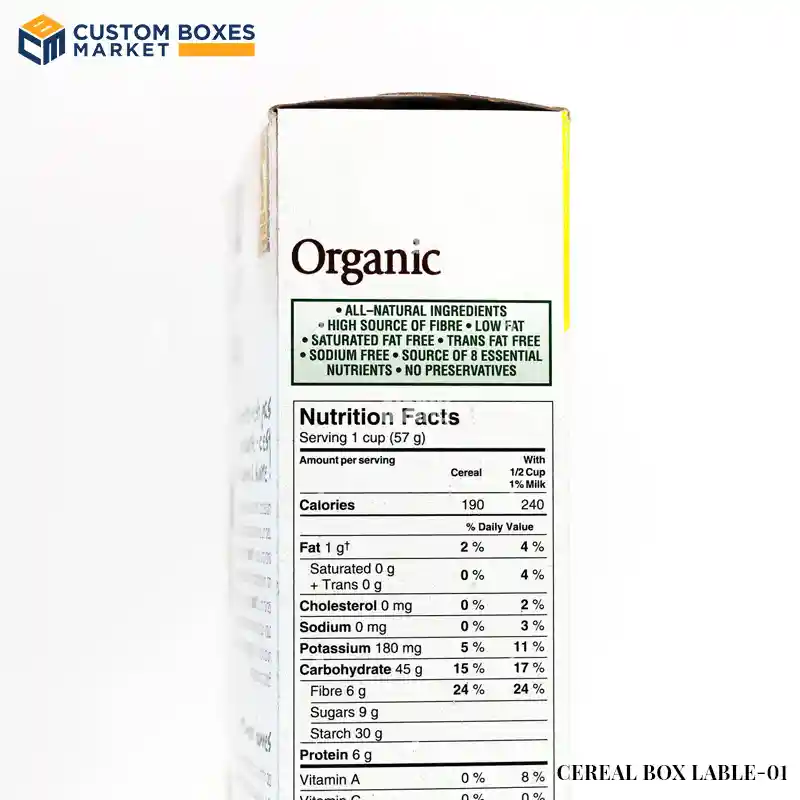

- In the case of custom labels where you want the design with the exact shape of the label then printing after die-cutting should be chosen

Sum Up!

Die cutting is a necessary step of custom box manufacturing. Whether you are doing it manually or you are handling it via digital software, it must be precise and it should follow the die line template. There are many different kinds of die-cutting processing depending on the final product requirement.

This process is easy but requires the expertise of a skilled person to give you custom packaging boxes. If you want accurate packaging with a unique style then CustomBoxesMarket is an ideal option for you, with our expert team and advanced facilities we will turn your dream packaging into reality.

Categories

Recent Posts

4 / March , 2026 Packaging Design

19 / February , 2026 Box Customization

16 / February , 2026 Box Material

3 / February , 2026 Gift Boxes

26 / January , 2026 Gift Boxes

6 / January , 2026 Sustainable Packaging

3 / December , 2025 Packaging Stats

17 / November , 2025 Custom Packaging

14 / November , 2025 Product By Industry

4 / November , 2025 Shipping Protection

28 / October , 2025 Custom Packaging

9 / October , 2025 Custom Packaging

7 / October , 2025 Shipping Protection

Get Free Quote

Related Products