An Ultimate Guide To Paper and Paperboard

April 8, 2024 Box Material

Paper and paperboard are an inevitable part of the packaging and printing industries. Paper is widely used for educational or documentation purposes, while paperboard is mainly associated with the packaging industry. From custom boxes for retail purposes to mailer boxes for shipping, all the packaging is manufactured widely using a variety of paper boards.

Paper and paperboard are numerous applications in everyday life. Even though digital platforms are widely used for documentation, a huge population still relies on hard copies of important credentials for which paper is used. Let’s see the difference between paper and paperboard with an in-depth analysis of paperboard.

What Is The Difference Between Paper And Paperboard?

Paperboard or cardboard is a hardened form of regular paper and is widely used in the construction and packaging sector. On the other hand, paper is relatively a thin and flexible material that is mainly associated with writing. While the sturdiness of paperboard makes it an ideal choice to pack products for safety, paper is a good option when one has to write or print certain credentials.

Paper Board And Packaging Industry

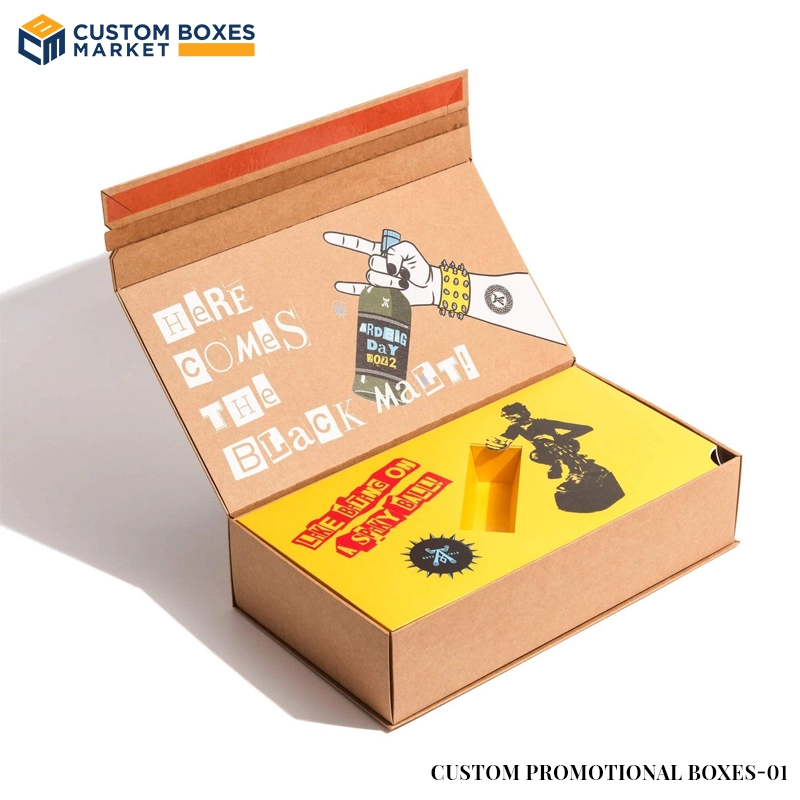

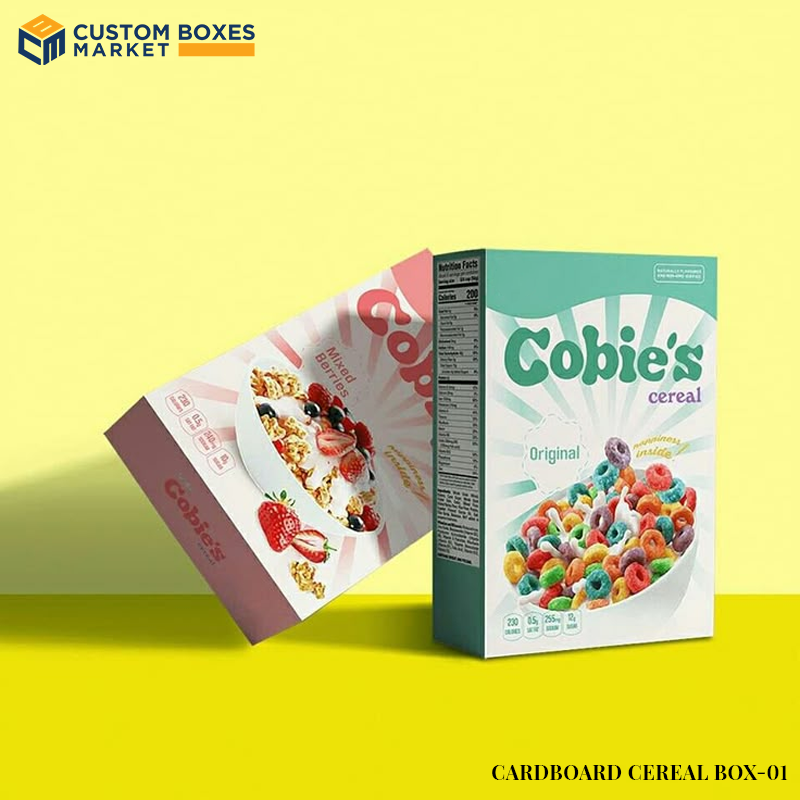

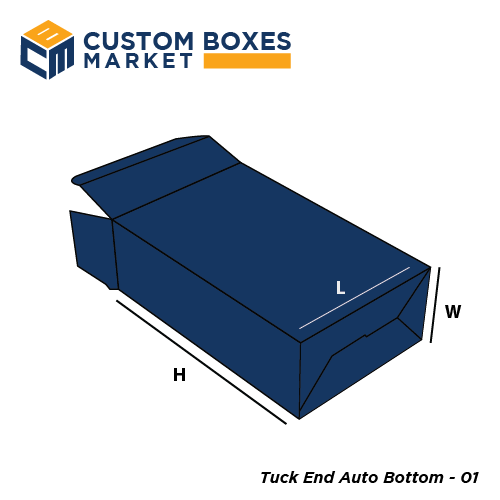

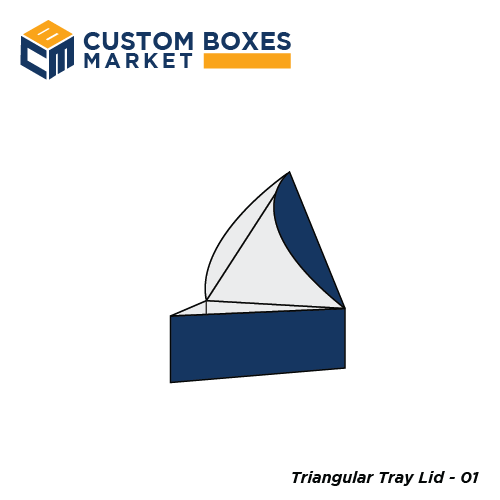

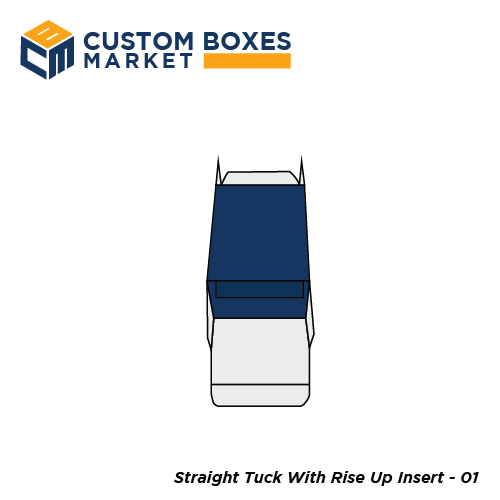

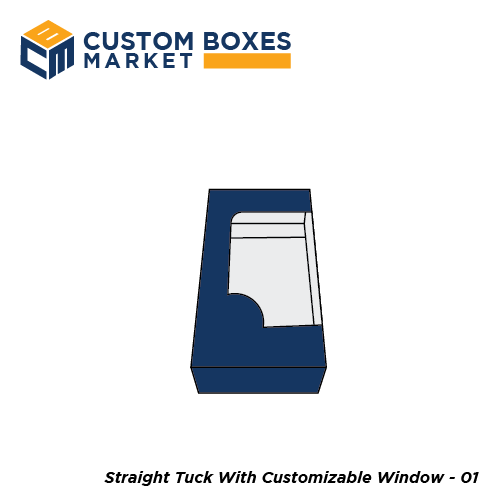

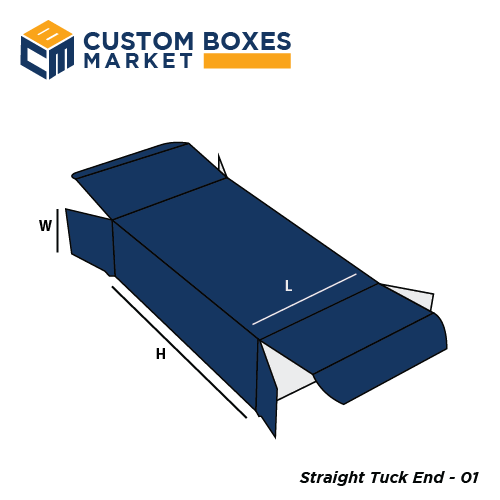

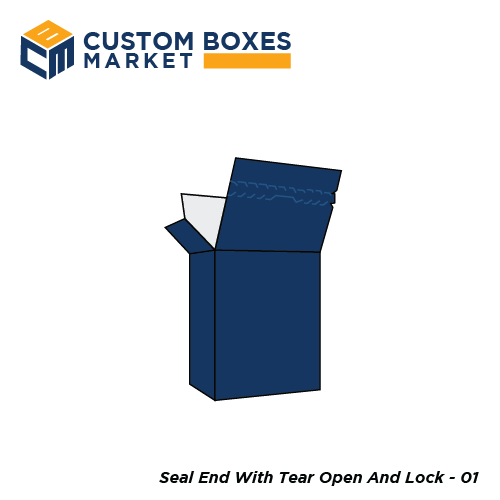

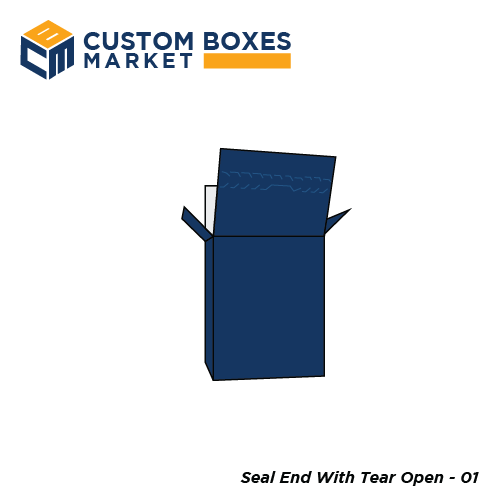

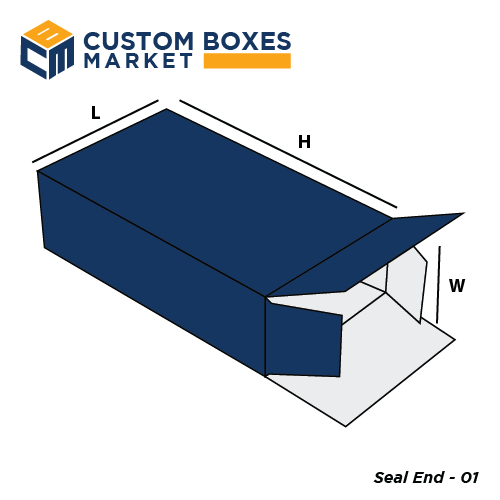

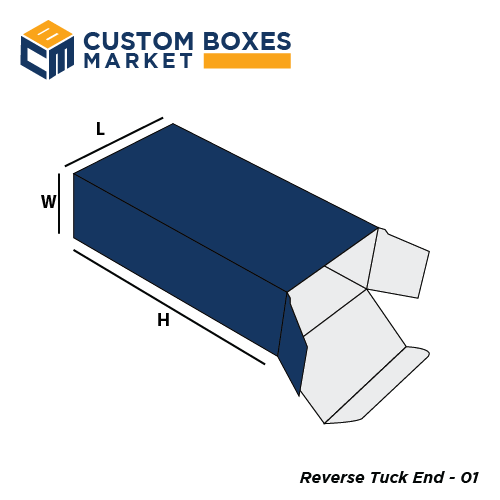

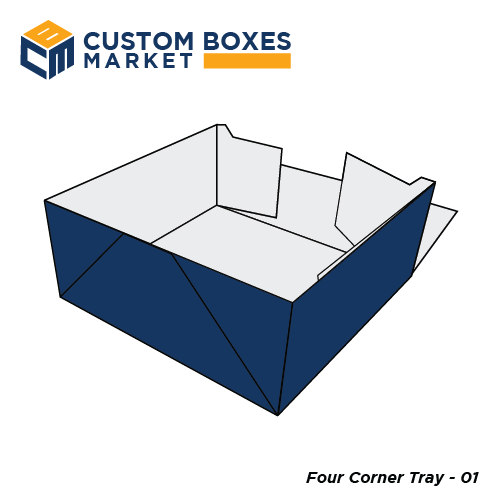

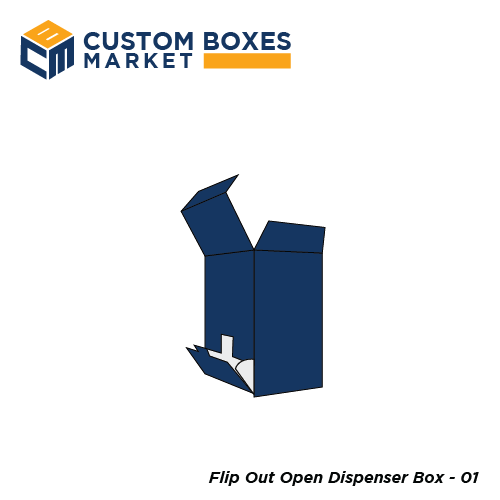

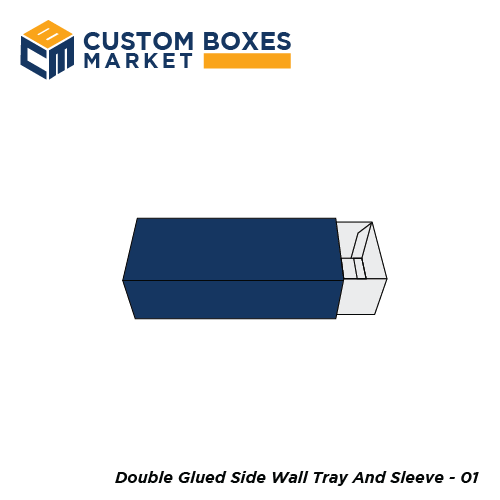

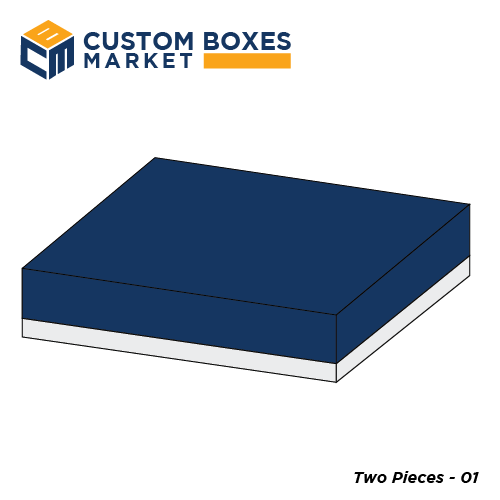

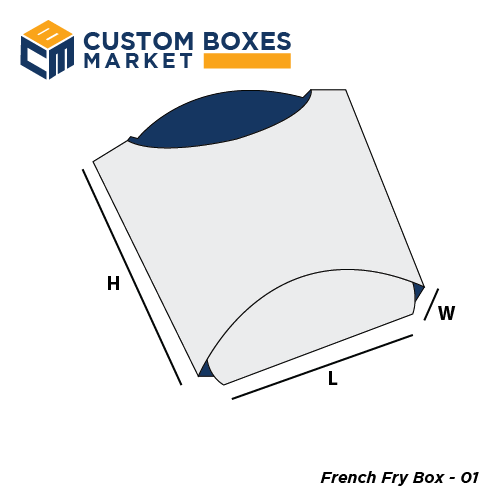

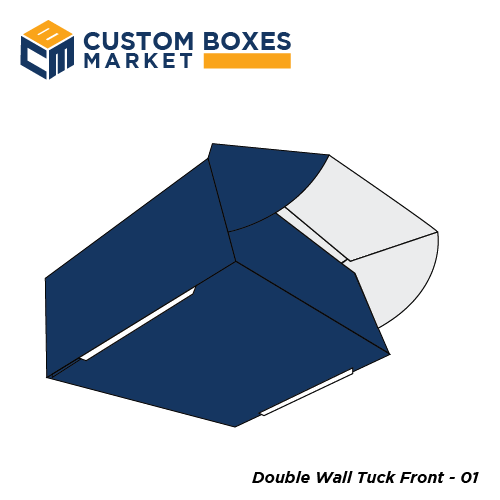

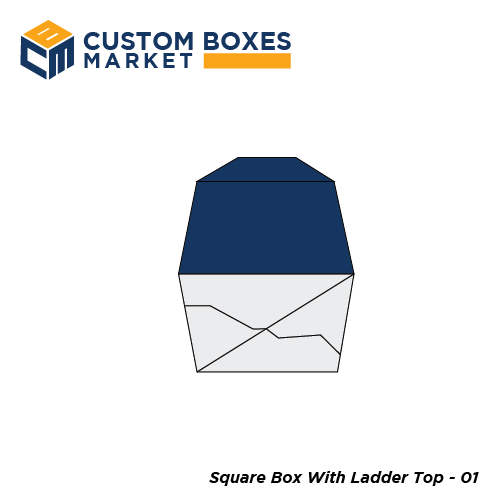

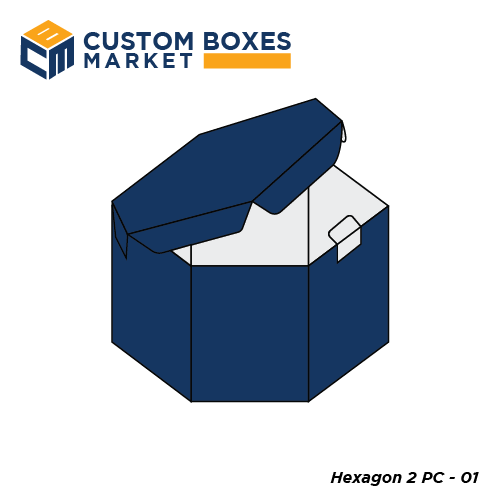

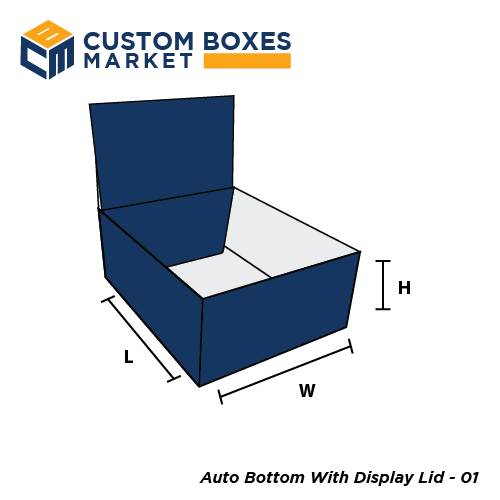

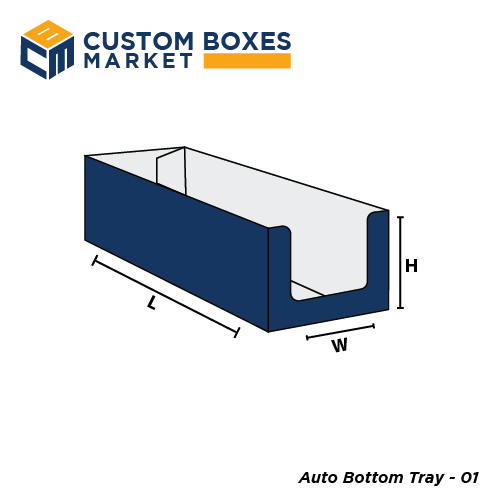

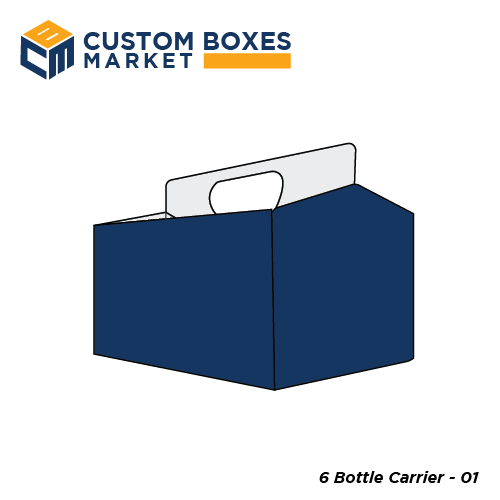

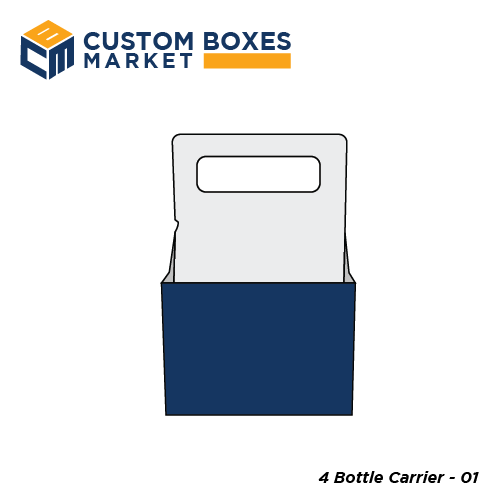

The custom boxes market is standing on paperboard as all the packaging boxes are manufactured with the use of paperboard. Features like durability, sturdiness, and tear resistance make paperboard a go-to material for product packaging in all sectors. Apart from these features, the various types of cardboard make it a popular choice.

Sheet Variation Of Paperboard

The types of paperboard depend on the types of fibers, bleaching agents, and the absence or presence of coatings. Apart from these features, cardboard varies on the basis of the number of plies used to produce the paper:

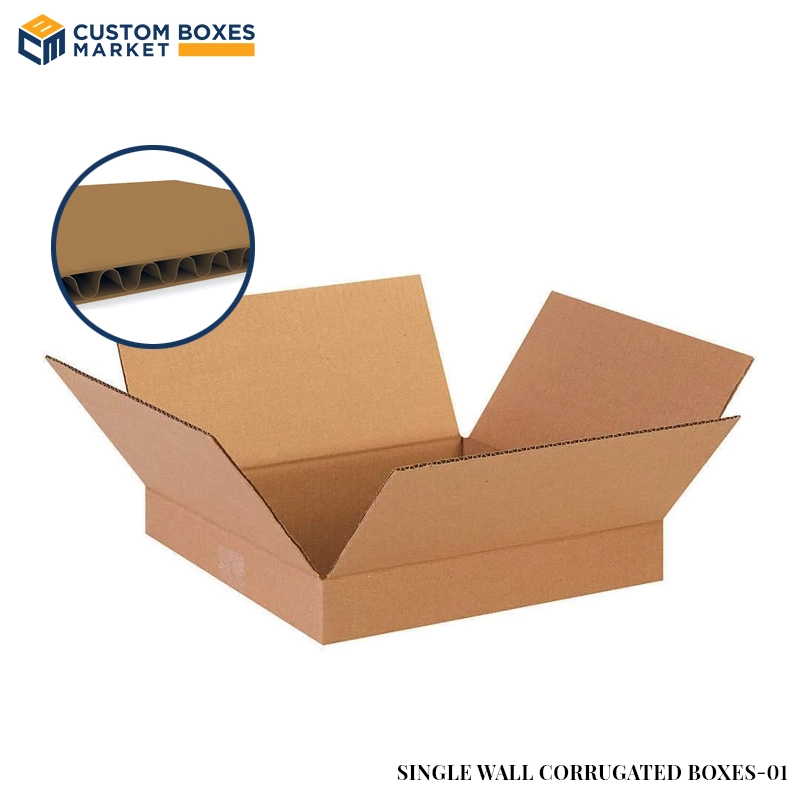

- Single-Ply: This material has only one layer of paperboard due to which it is light in weight. For small packaging boxes and for shipping boxes this material is the preferred choice.

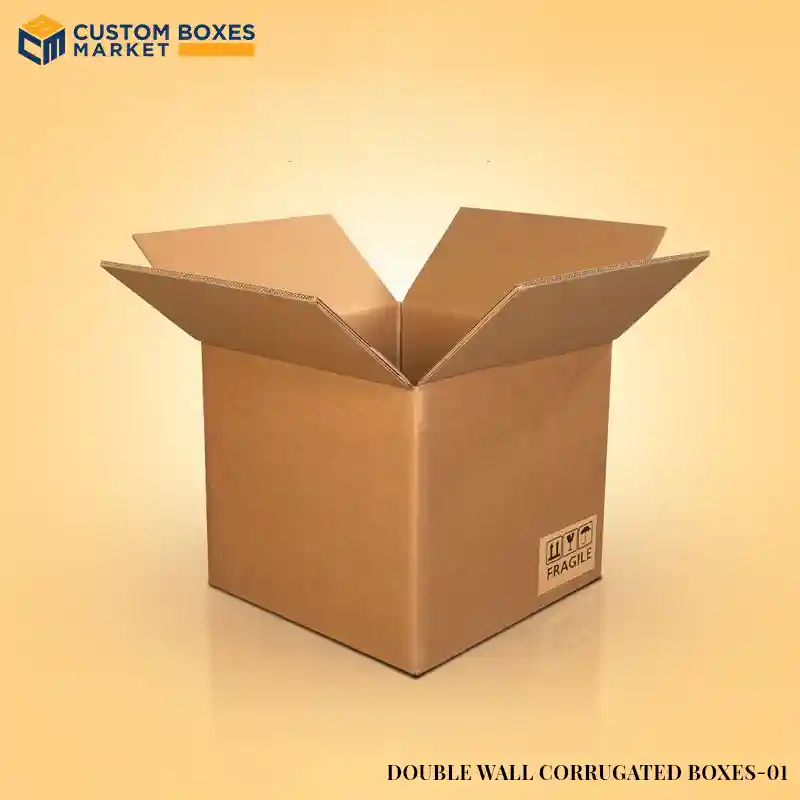

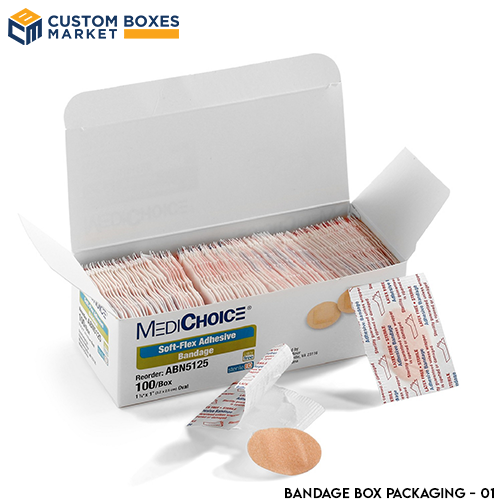

- Double-Ply: Double-ply paper has two layers of cardboard that make it an ideal option for manufacturing packaging boxes that require a moderate level of protection. These boxes include retail packaging boxes, medicine boxes, etc.

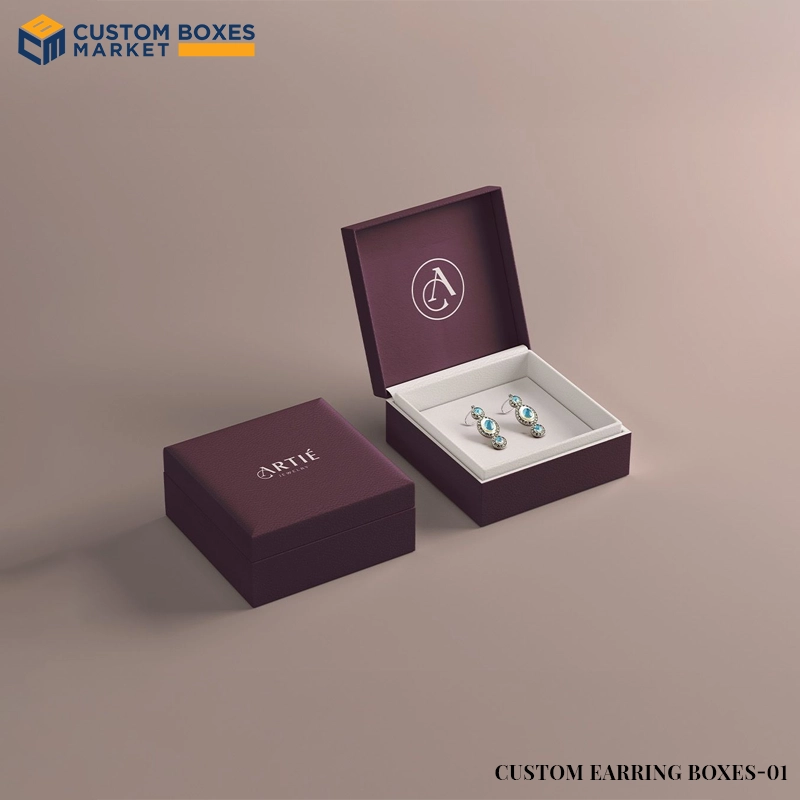

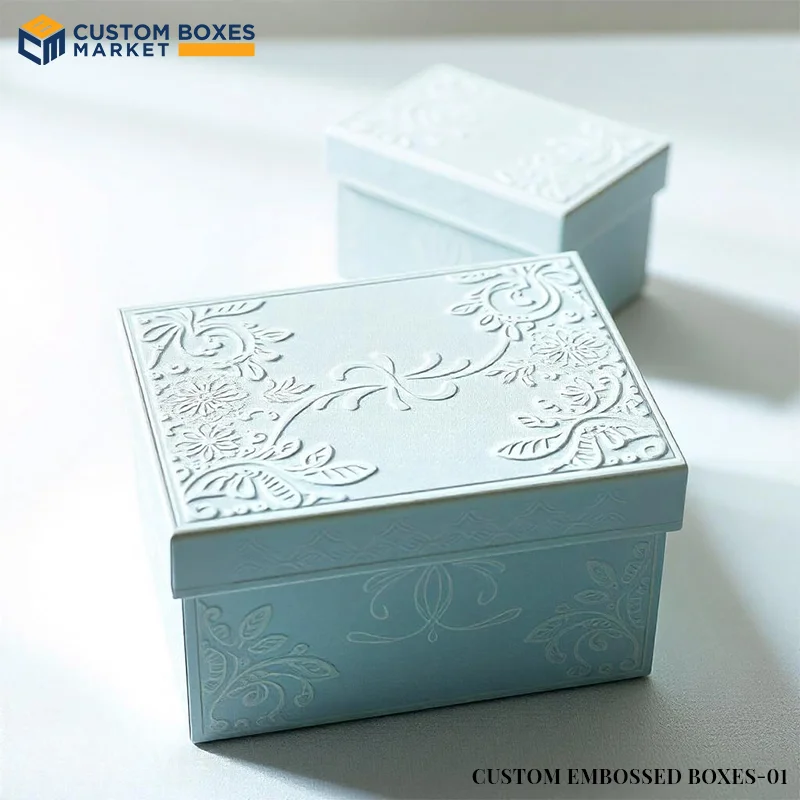

- Tripple-Ply: As the name indicates in triple-ply material three layers of cardboard are used that give this material an exceptional quality and strength. For high-end packaging boxes such as watch boxes, jewelry packaging, or business card boxes, this material is a perfect choice.

Types Of Paperboard

With advanced manufacturing facilities and a wide understanding of materials, the paper industry has devised various means to give quality along with versatility to cardboard. The selection of materials based hugely on the type of packaging such as the thickness of material for custom display boxes will vary largely from the material used to manufacture die cut folders or donut trays. Below are some types of cardboard:

-

Uncoated Paperboard

Uncoated paperboard has a natural texture as no additional coating is done on this paper. This material has a high porous surface which makes it highly absorptive. Due to this, uncoated cardboard is not a good choice for printing. Nonetheless, it can be used for folding cartons, for book covers, and bindings.

-

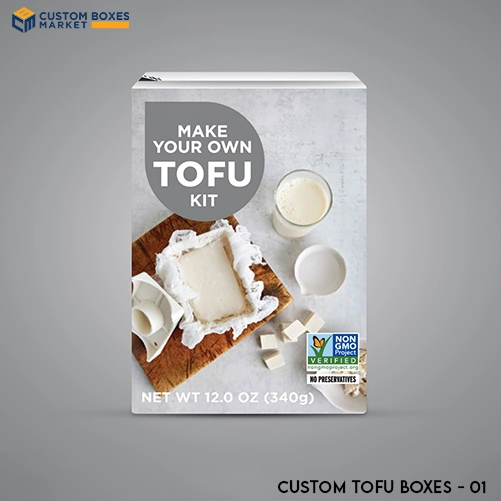

Coated Paperboard

As the name indicates this material is coated with clay or other coating polymers. Layers of clay are coated on the upper surface of the paper. This coating enhances the surface properties of the material and makes it fit for printing. Apart from this, a smooth and glossy finish appears on the paper that gives a premium look. You can use

-

Solid Bleach Sulfate

Solid bleach sulfate is a material of exceptional quality that is made with a combination of softwood and hardwood. The upper layer of this bleached paper is clay-coated which gives a pristine shine to the material making it perfect for printing. For custom food packaging, cosmetic boxes, and medicinal product packaging SBS is used.

-

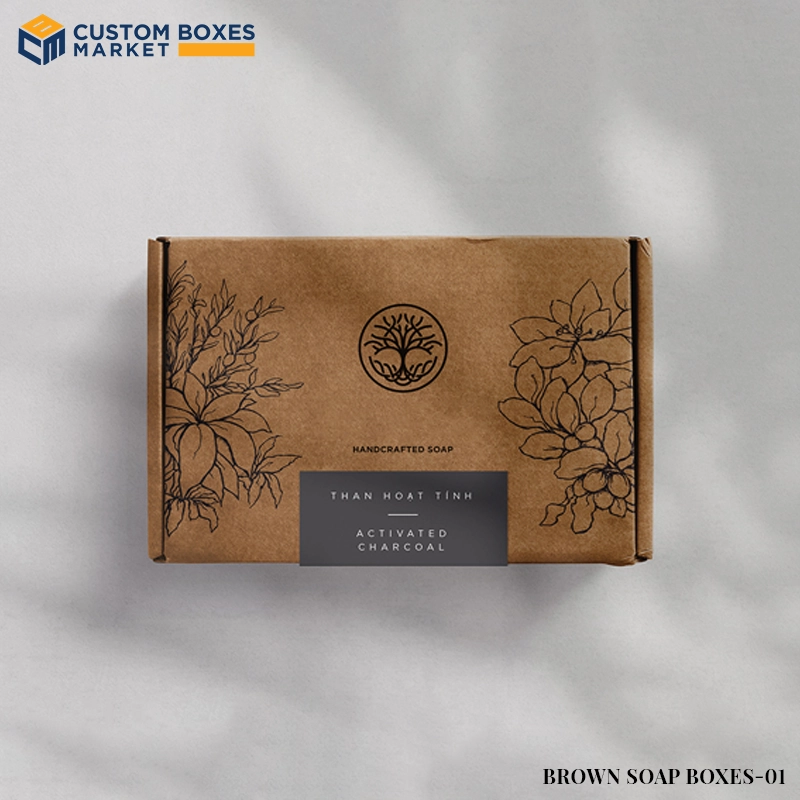

Coated Unbleached Kraft

Coated unbleached kraft material is made of two different layers of wood fiber that are coated with clay. The lower layer is made of softwood obtained from pine trees and the upper layer is made of hardwood fibers. The top of the material is clay coated to make this material feasible for printing. The long pine wood fibers make coated unbleached kraft resistant to tearing. This material is used for the packaging of detergents, beverages, and some heavy-duty packaging boxes.

-

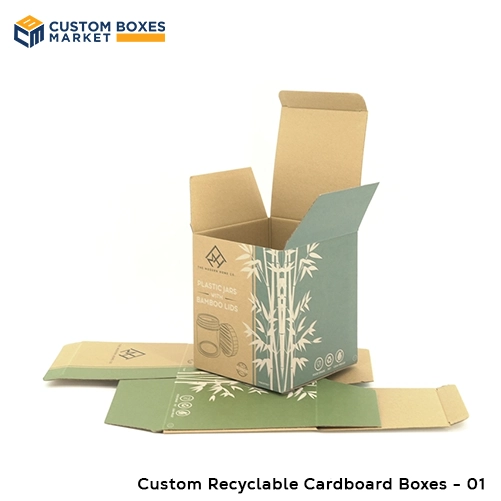

Coated Recycled Paperboard

Coated recycled material is an excellent option to reduce waste generation and carbon footprint. From paper manufacturing facilities, corrugated material, and used boxes, this material is produced. The top white fiber of the material is coated and used to manufacture packaging boxes. Mainly coated recycled paperboard is used as body stock in rigid boxes.

Wrap Up!

Paper and paperboard are the essentials of the packaging industry. Particularly paperboard is the main foundation on which the custom boxes market is based. The sturdiness, cost-effectiveness, and high variety make paperboard a primary choice for manufacturing custom boxes. We at CBM use the most high-quality and premium paperboard that gives our clients boxes of top-notch quality.

Categories

Recent Posts

3 / February , 2026 Gift Boxes

26 / January , 2026 Gift Boxes

6 / January , 2026 Sustainable Packaging

3 / December , 2025 Packaging Stats

17 / November , 2025 Custom Packaging

14 / November , 2025 Product By Industry

4 / November , 2025 Shipping Protection

28 / October , 2025 Custom Packaging

9 / October , 2025 Custom Packaging

7 / October , 2025 Shipping Protection

24 / September , 2025 Custom Packaging

18 / September , 2025 Custom Packaging

18 / September , 2025 Box Material

Get Free Quote

Related Products