5 Important Questions to Ask When You Buy Custom Packaging

July 25, 2024 Business Growth, Custom Packaging

Custom Packaging is an important factor in the enhancement and protection of products. You must ask the necessary questions while purchasing the packaging boxes. The demand for custom boxes has been increasing for the passage of time because of the increasing competition in the industry. Because of that businesses are contacting custom box experts so that they can customize the right boxes for your products keeping in view the dimensions of the products. In this blog, we will discuss the top 5 questions you must ask before buying packaging boxes.

What Type Of Material Do You Offer?

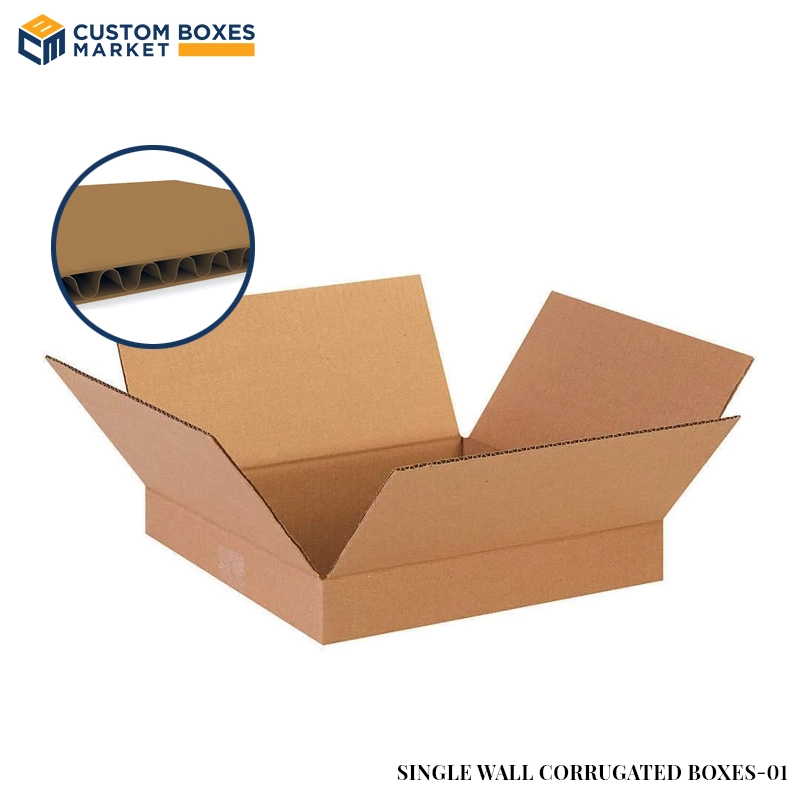

Choosing the right packaging is the initial step of packaging boxes. As a customer, you must ask your vendor about the type of materials they offer for custom packaging. You must ask about the features and characteristics of the material and identify what is the type of material you should choose. There are a variety of materials that different packaging companies offer some of them are included:

- Buxboard

- Chipboard

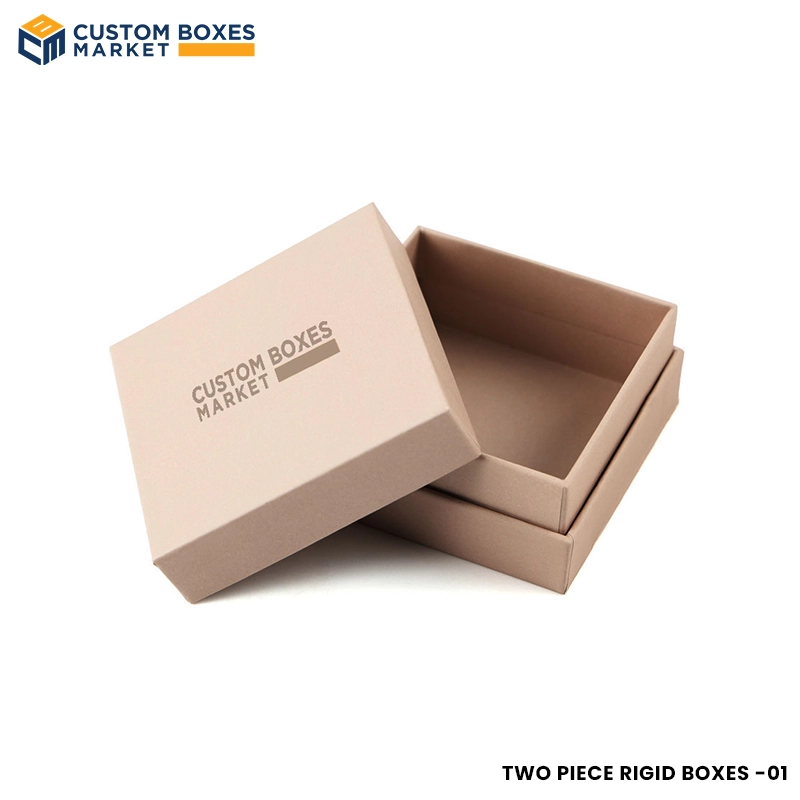

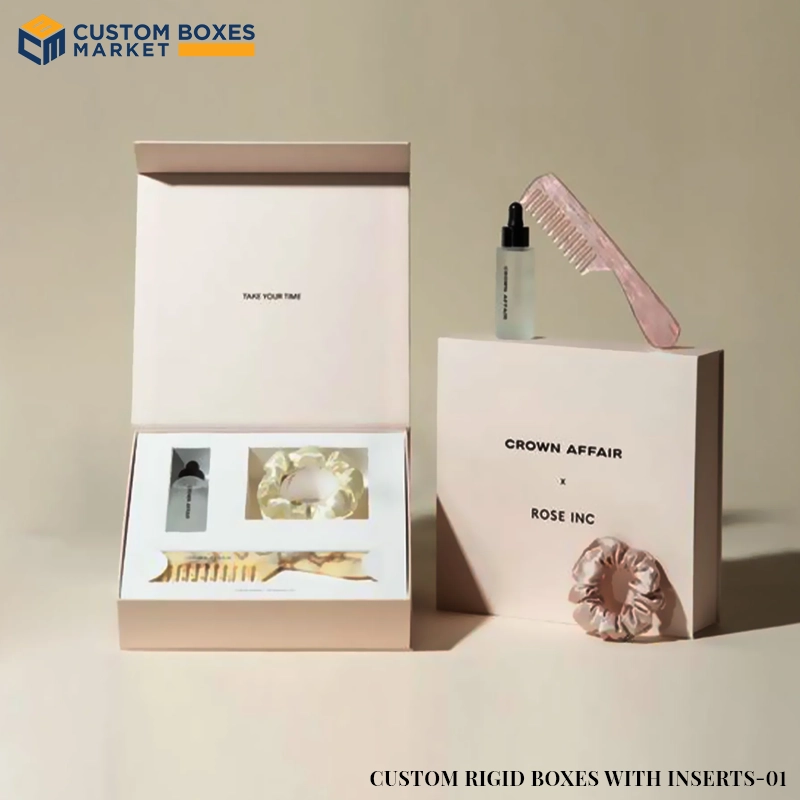

- Rigid

- Cardboard

- Corrugated

- Kraft

Why Finishing Is Important?

Finishing options are necessary for a packaging box because they not only protect your boxes from the external environment like dirt, scratches, etc, and the rigors of shipping but also improve the visual appeal of your boxes will help you grab the attention of your customers and boost sales. You can choose whatever finishing technique suits you the best and fits your budget. You can ask your packaging team about the kind of finishing techniques they provide for the enhanced visual appeal of products. Some common types of finishing techniques are as:

- Embossing

- Debossing

- Gloss finish

- Matte finish

What Protection Do The Products Need?

Protection of products is necessary, as it prevents loss, theft, and wear and tear during shipping. Several environmental factors affect the product during shipping and transportation. Keeping your product secure these factors will help you in secure delivery of products and gain customers’ trust which will have a positive impact on your brand.

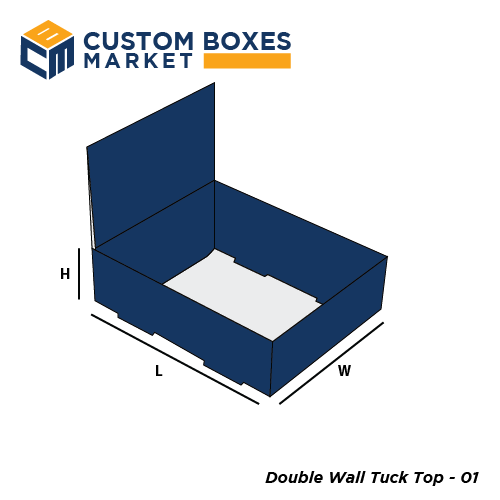

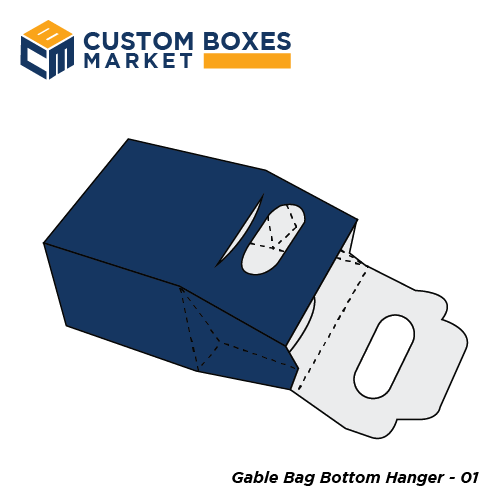

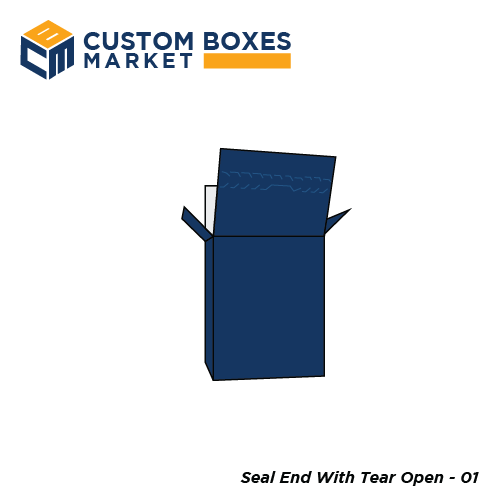

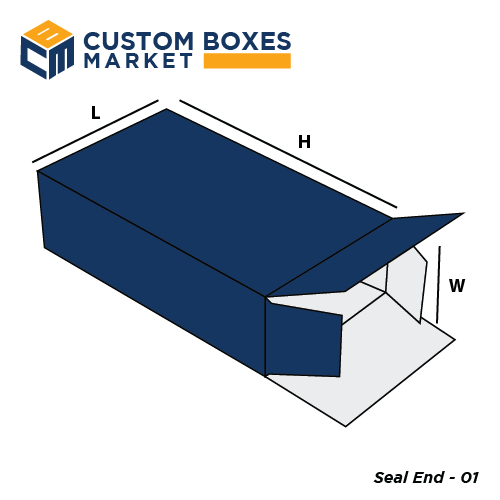

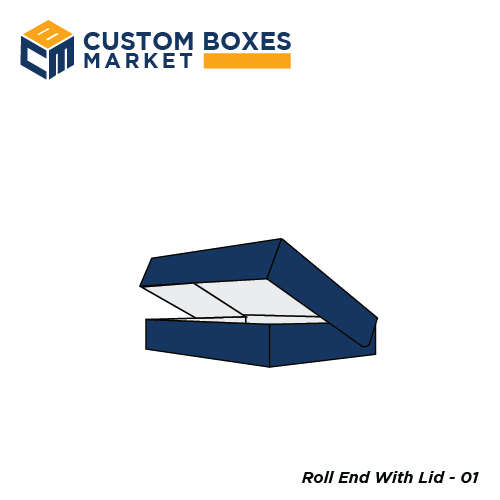

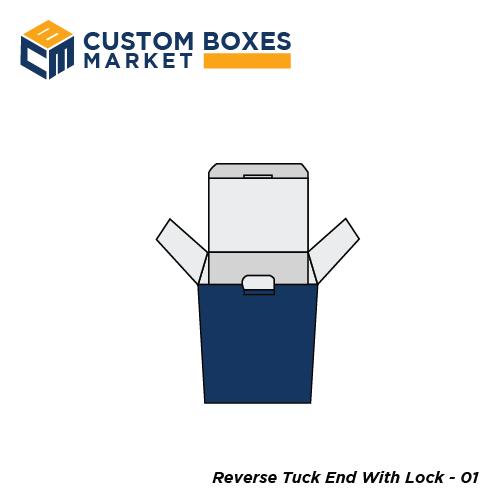

What Type Of Seal Should I Add To My Boxes?

Different types of packaging boxes require different closure seals. It has a significant effect on the appearance of your boxes. They ensure that the box remains closed for a long time and endures the rigors of shipping and transportation. You can choose the closure method that suits you the best according to your product type and size. Some common types of closing seals are:

- Taping

- Stapling

- Gluing

- Strapping

Taping

It is the most common closure method for boxes. It is widely used all around the world for secure closures. In this, the gummed tape is applied on the surface of the flaps of boxes, it is a versatile way to close boxes. It can be used for different boxes and sizes.

Stapling

This method involves stapling the box flaps securely. It is used for closing of heavy-duty boxes. You can use this technique for the closure of your boxes.

Gluing

This technique is commonly used to ensure the secure closure and permanent closure of boxes. In this method, the flaps of the boxes are tightly closed by using adhesives.

Strapping:

Strapping is another method used for the closure of packaging boxes./ it can be made of different materials. Keeping in view the type of products you want to ship

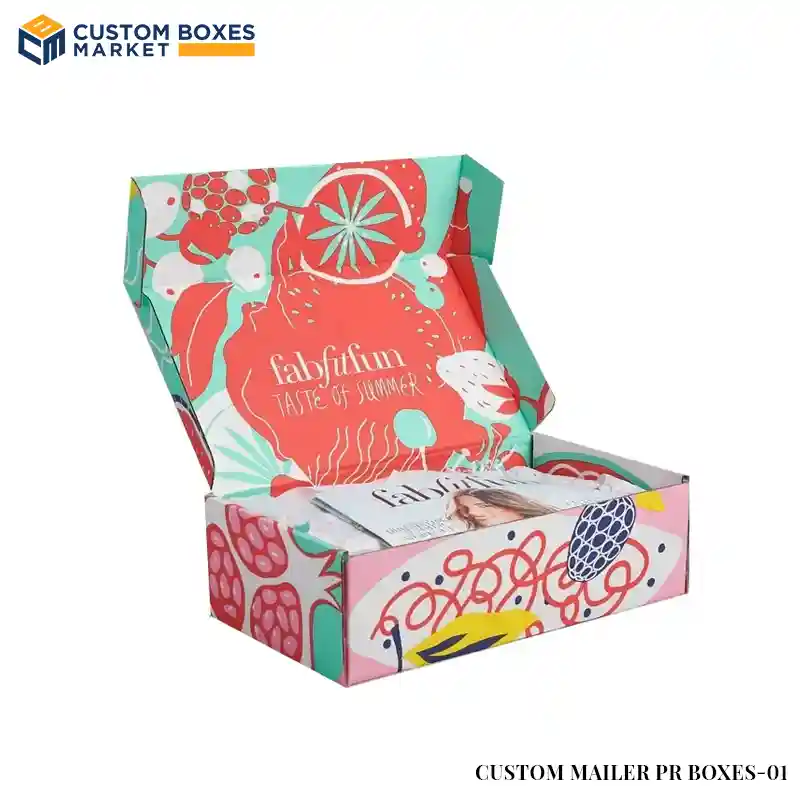

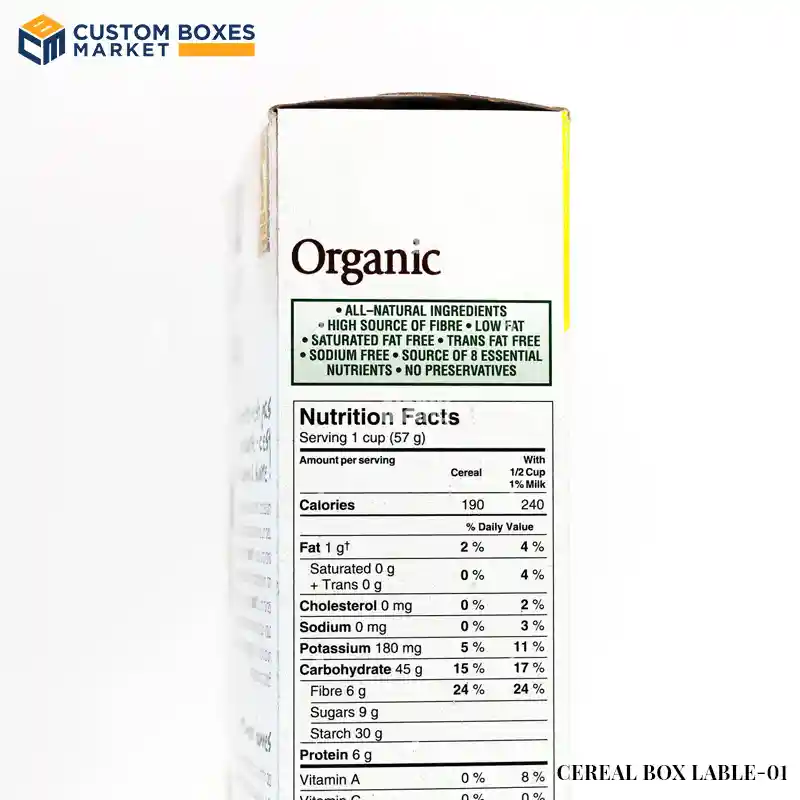

What Kind of Printing or Labeling Is Required?

Printing and labeling are the two important elements that help you elevate your brand identity. As a customer, you must ask your packaging experts about your concerns regarding printing and labelling. Also, discuss the type of labels and printing that would suit your brand and at the same time fit into your budget. Here are some common printing and labelling options:

Offset Printing: Offset printing method, metal plates are used to transfer ink onto paper cardboard, or other material. It is mostly used for large-scale packaging orders.

Digital Printing: Digital printing is a premium printing method that uses inkjet technology for printing designs directly onto packaging materials. It is often used for small-scale orders or custom packaging.

Screen Printing: In screen printing method that uses a screen to apply ink onto materials. It is often used for bulk orders or packaging with complex designs.

Labeling: Labeling involves applying pre-printed labels to packaging materials. It can be done manually or using automated labeling machines.

When choosing printing or labeling options, consider the volume of your packaging order first, the level of customization required, and the desired level of quality. For instance, if you need high-quality printing, digital printing may be the best option.

Conclusion

When you want to make packaging boxes for your products. You must provide the packaging vendor, provide them with the right information regarding your products so that they can customize boxes that fit perfectly with your product. If you have any concerns regarding the process of packaging you can ask to clear out your doubt. It will also help in developing a trustful relationship between you and your box experts.

Categories

Recent Posts

4 / March , 2026 Packaging Design

19 / February , 2026 Box Customization

16 / February , 2026 Box Material

3 / February , 2026 Gift Boxes

26 / January , 2026 Gift Boxes

6 / January , 2026 Sustainable Packaging

3 / December , 2025 Packaging Stats

17 / November , 2025 Custom Packaging

14 / November , 2025 Product By Industry

4 / November , 2025 Shipping Protection

28 / October , 2025 Custom Packaging

9 / October , 2025 Custom Packaging

7 / October , 2025 Shipping Protection

Get Free Quote

Related Products