A list of Durable Materials For Custom Boxes. What Is the Right Fit For You?

November 29, 2024 Box Material

Packaging is the core of any business that can either make or break it. About 67% of American consumers reported that their purchase decision was influenced by packaging materials. So, doesn’t matter if you are running a small cosmetic shop or a luxurious restaurant, packaging is an important element to consider. Keeping in mind the current need for quality packaging, businesses should spare some time and budget for the visual presentation of their product only if they want to win the race of packaging.

One of the most essential elements for packaging is the material of custom boxes. Materials are just like the ground on which a whole house is built. So, the material is the base of the product packaging. If you want to know what materials are available in the market and which ones are more durable and suitable for you then read ahead.

5 Ps Of Packaging

Let’s first discuss the what are the main things that influence your packaging. Packaging is a sensitive matter to pay attention to because it builds the first impression on customers. Here are the 5 main Ps of the packaging that you should keep in notice while choosing packaging material or custom boxes:

Promote

Packaging is like a portable billboard that promotes your brand invisibly. In this way, durable and sturdy materials are a must so consumers prefer your brand over others.

Position

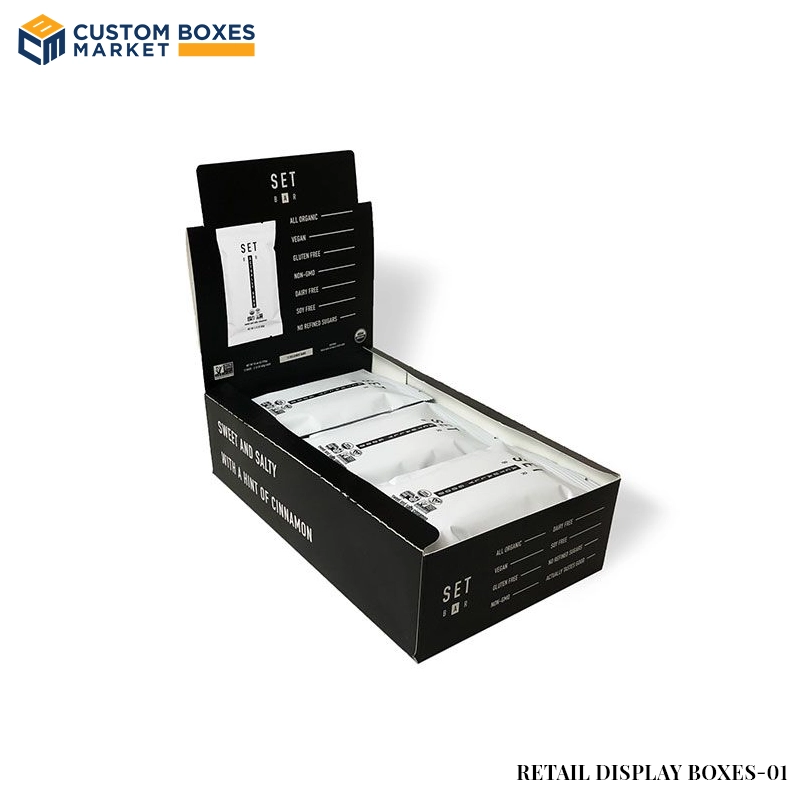

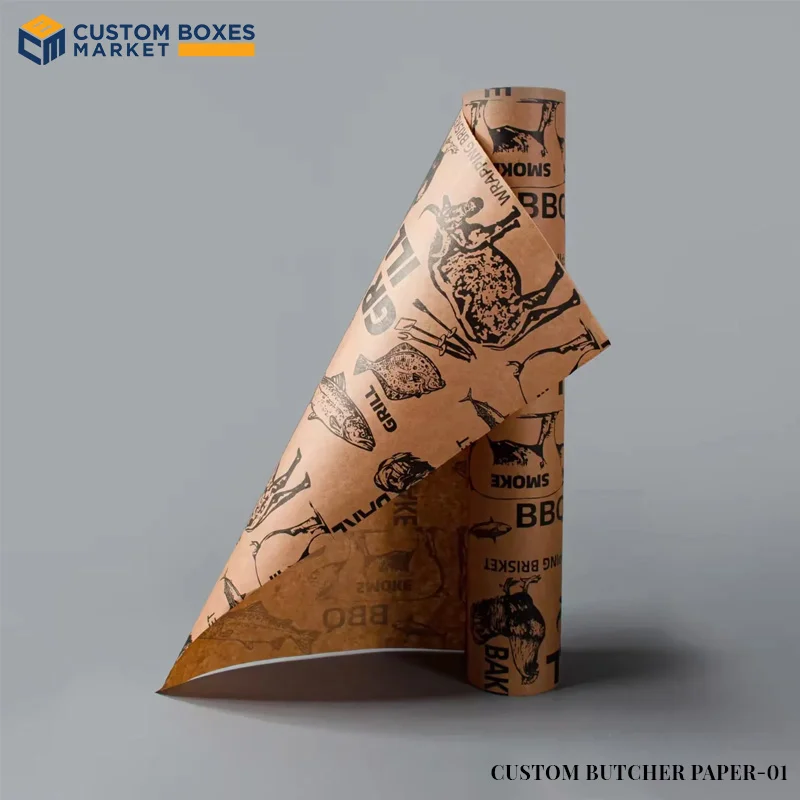

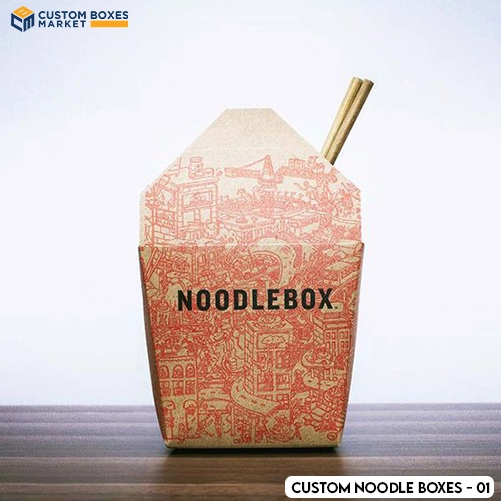

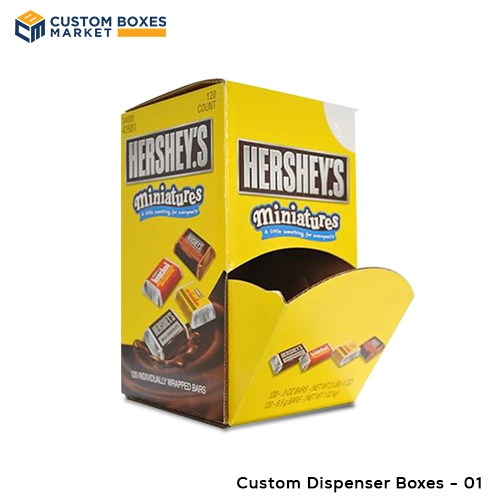

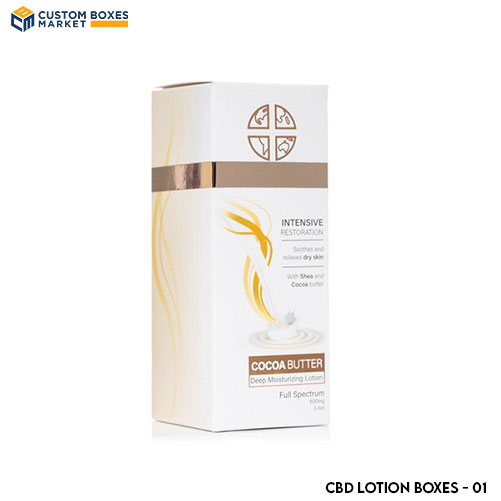

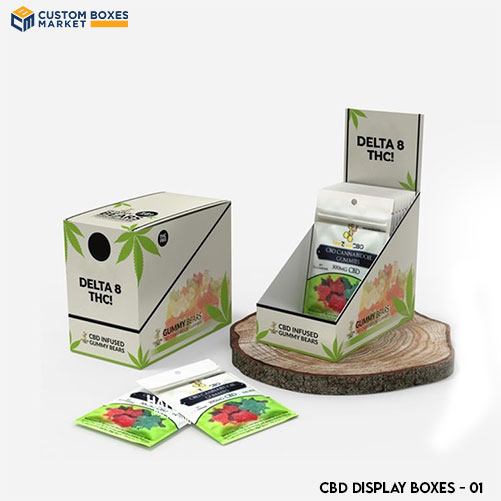

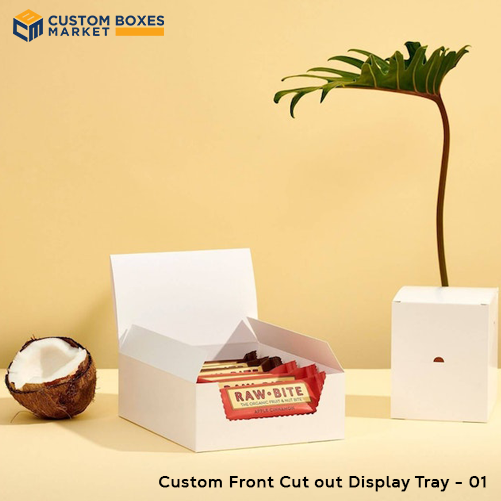

Position in packaging includes how your product is placed in front of customers. This involves displaying your products on the shelf so the material is again the core element to consider. Some brands use custom display boxes to position their products efficiently.

Present

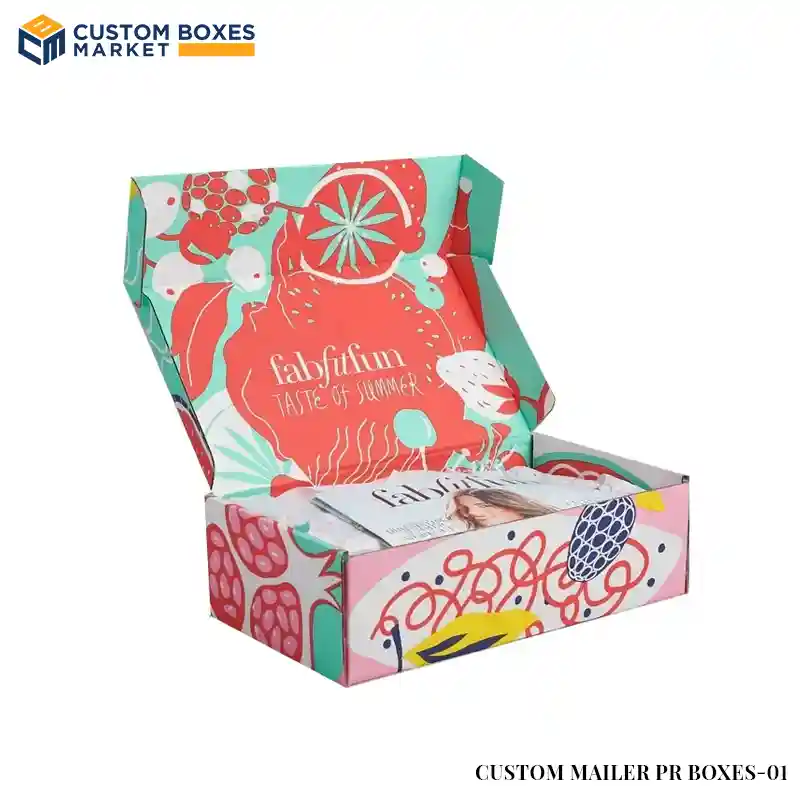

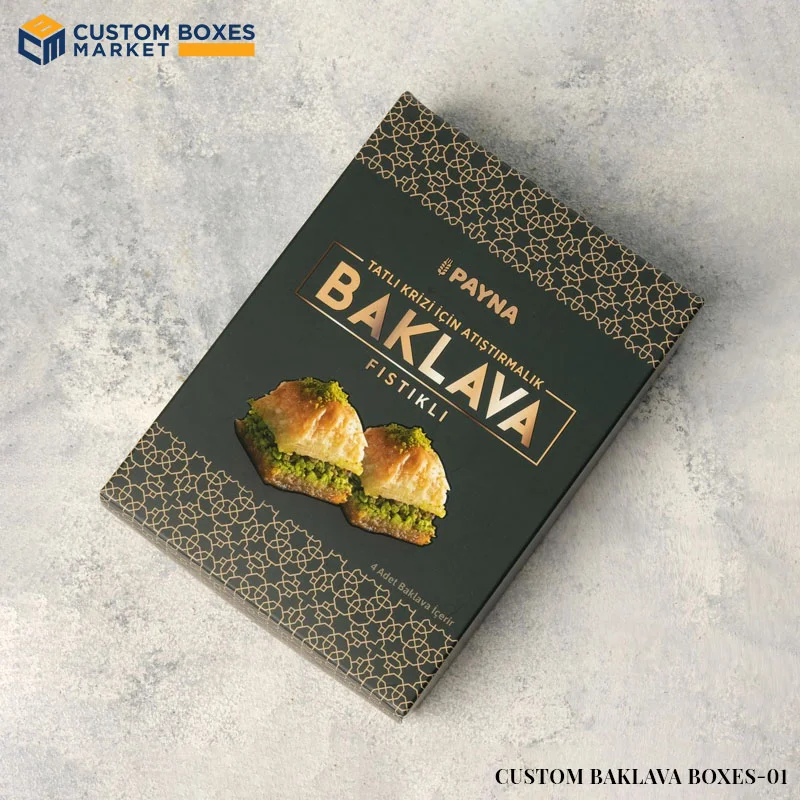

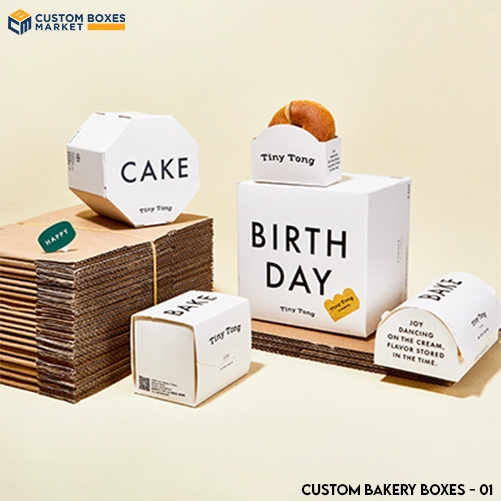

Your custom box is a blank canvas of creativity where you can showcase how distinct you are from other brands. Choosing materials wisely will help you present your product with confidence.

Price

People will never waste their money on bad-looking packaging. The price of your product includes many important factors one of which is material. When customers hold your product in hand, they will analyze your custom box from corner to corner and quickly analyze if the price justifies the product or not.

Protect

Protection is directly proportional to the materials used for packaging. Every brand needs a secure delivery of their products so their reputation must remain positive. So, this is only possible by not compromising on the quality of the material and using only durable ones.

A List Of Materials Used For Packaging Products

A variety of materials are available for custom boxes catering to the different requirements of each business. A list of materials are as follows:

Paper-Based Materials

- Corrugated cardboard

- Chipboard

- Kraft paper

- Paper board

Plastic Materials

- Rigid plastic

- Polyethylene

- Polystyrene

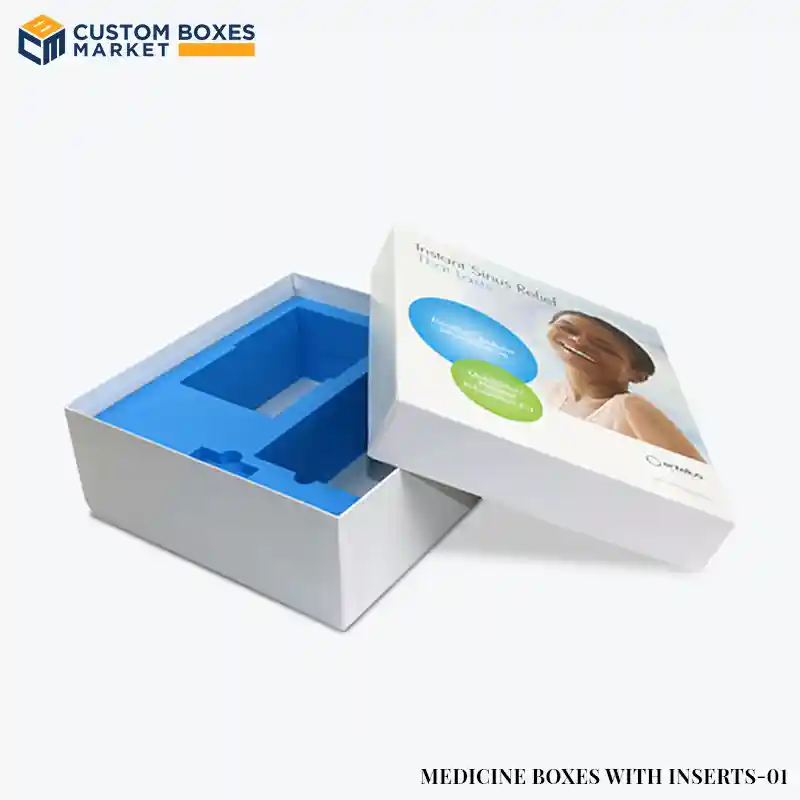

Foam Materials

- Polyester foam

- Polyethylene foam

- Foam inserts

Textile Materials

- Nylon bags

- Cotton bags

- Fabric wraps

- Jute bags

Metal Materials

- Aluminum foil

- Tinplate

- Stainless steel

- Metalized film

Common Durable Materials For Custom Boxes

Now, after reading the available materials you think who are the most durable ones? Don’t overthink, we are here to guide you on the subject. Following are the firm materials options you can utilize to increase your brand perception:

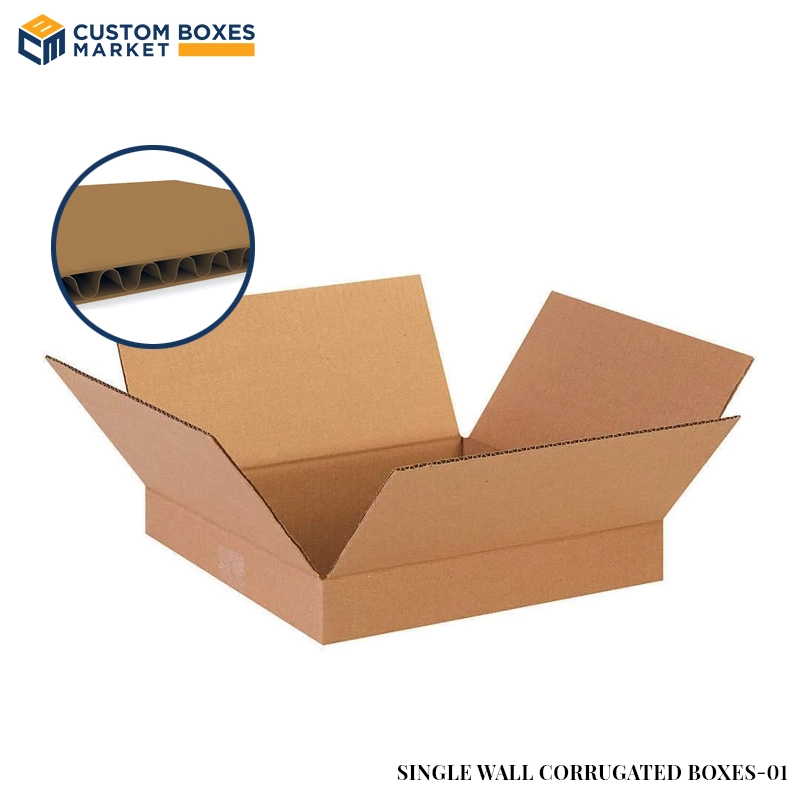

Corrugated Cardboard

Often known as corrugated cartons, corrugated cardboard consists of multiple (typically three) layers of kraft paper. Layers can be customized according to the product being placed inside. One fluted layer is placed between two liner boards that give maximum protection while shipping. Corrugated boxes are versatile, resist bending, ensure high product safety, and are reusable.

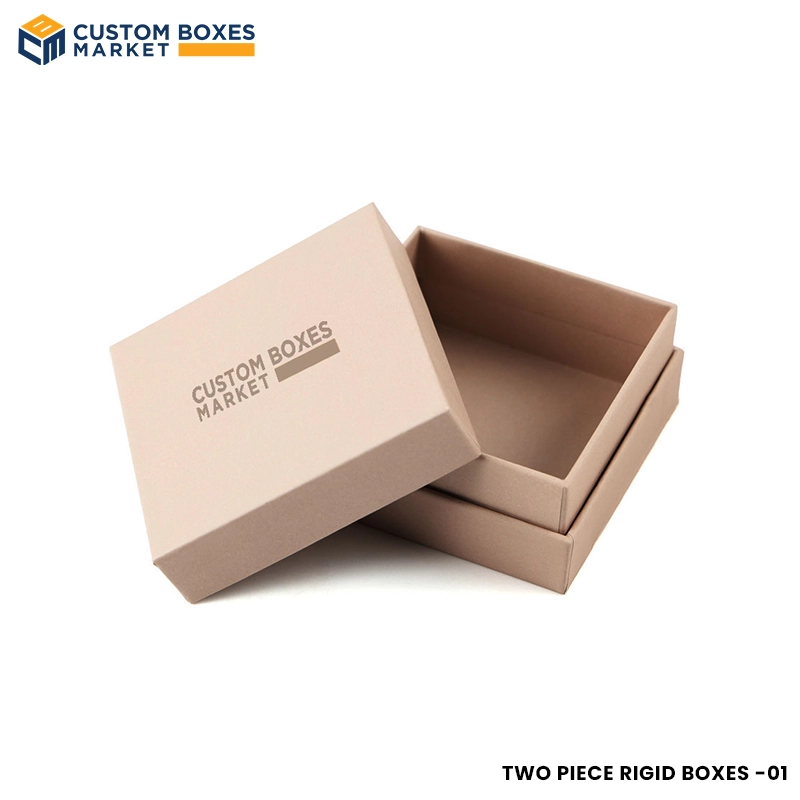

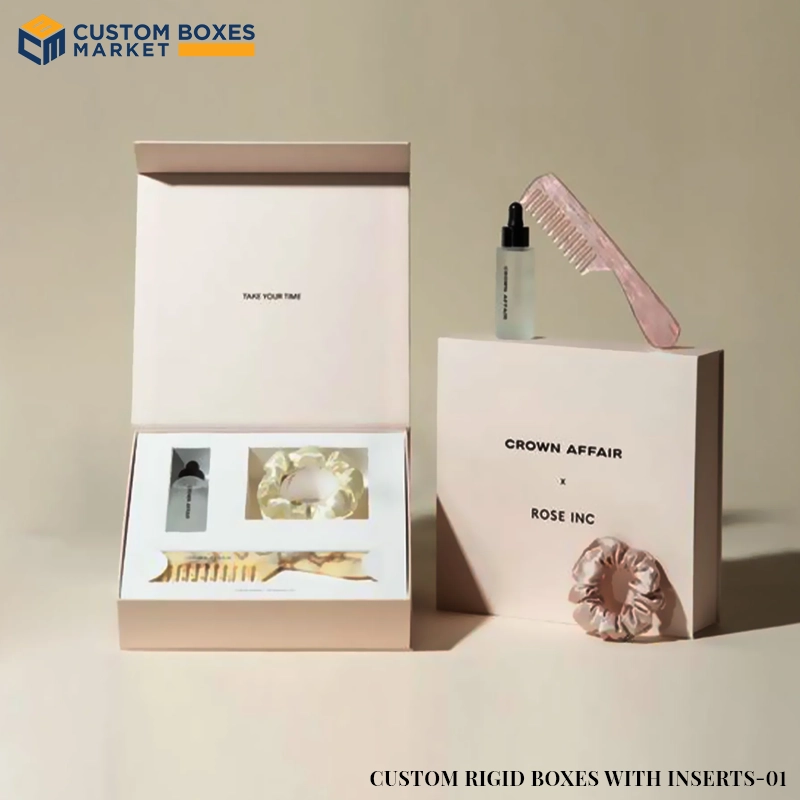

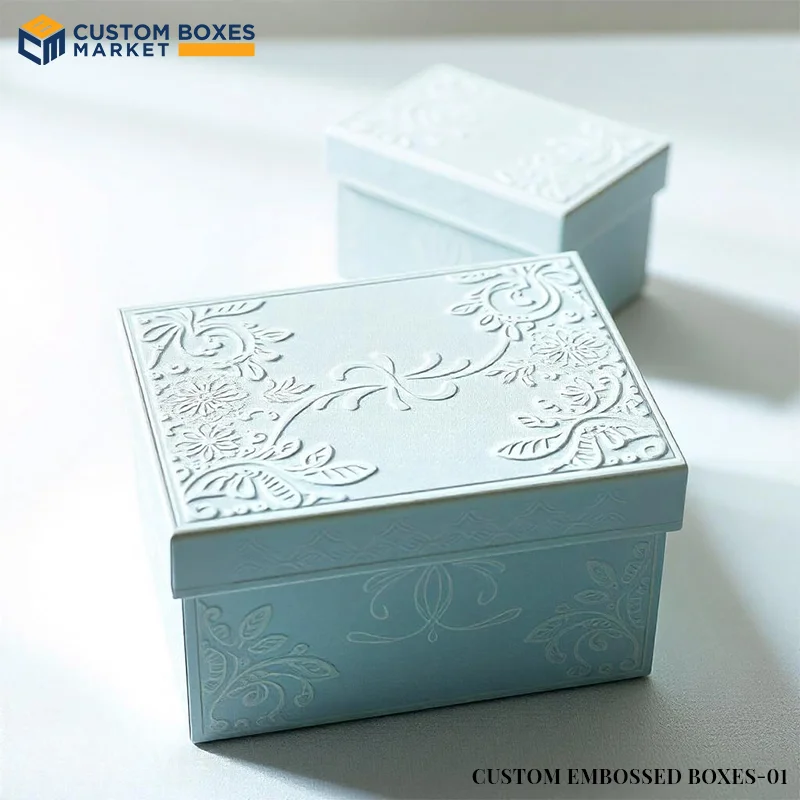

Rigid Board

Rigid boards are commonly used because not only they are sturdy but also give a luxurious feel. The cost of rigid boxes is generally high and they are reusable. This material has high density which makes printing challenging. Rigid boards have various applications including luxury packaging, book binding, signage, and furniture.

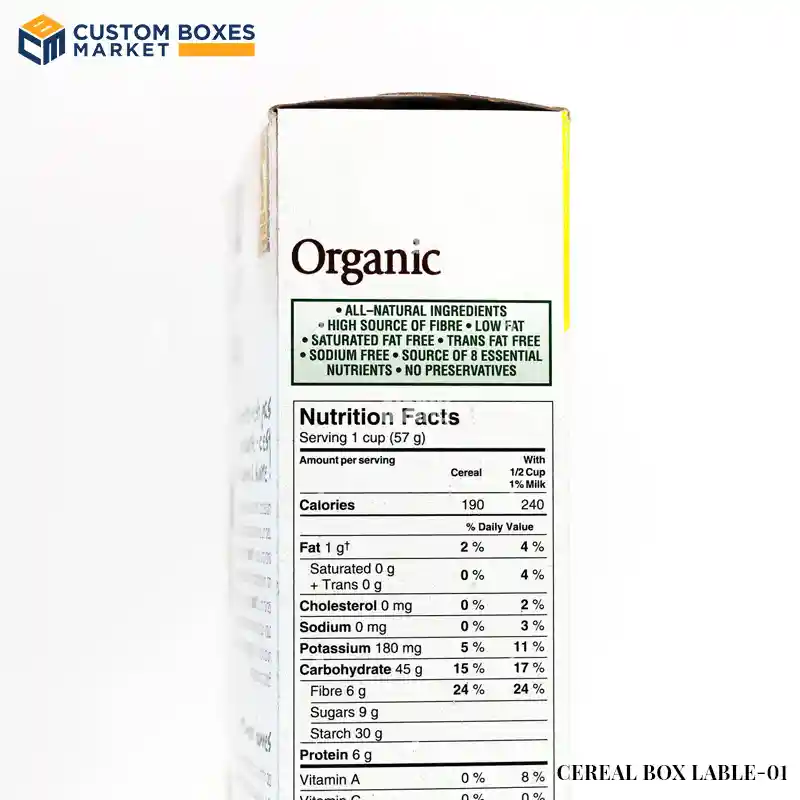

Paper Board

Paperboard is also a popular choice among brands due to its various industrial applications. This is a stiff and durable paper-based material that is generally made from wooden pulp. Paper boards are lightweight so they also help in minimizing storage and shipping costs.

Chipboard

Chipboard is a 100% recyclable material that is a budget-friendly choice for people looking for quality and functionality side by side. Chipboard boxes have a wide range of customization options and printability makes them a beneficial choice for branding.

Recycled Bux Board

Custom Bux board boxes are known for their affordability, strength, and ultimate protection of the product. This material is a mindful choice for people looking to promote their business at cheap rates. Different finishing options can be incorporated on bux boards such as matte UV, gloss/matte/UV lamination, embossing, and foil to help you promote your brand while staying trendy.

Key Material Properties To Consider While Choosing Material

Choosing material could be quite challenging because you have to consider many important things for it. Keeping in mind your target audience, budget, and product types are common components. While selecting a material, these are the things you should look for:

Thickness

You can’t just randomly select a material without understanding its thickness. Look into what product you are selling and how much thick material it needs for proper protection.

Moisture Resistance

No one wants to buy a product whose packaging looks all greasy and stained. Moisture or tear resistance is important to consider especially in food packaging. However, all mentioned materials are water-resistant so your product is delivered with care.

Compression Strength

The compression strength of the material is the ability to bear external forces, jumps, and pressures without scuffing and collapsing. It has a huge impact on the preservation of goods and minimizes product loss. Always look for material that has maximum compression strength so your product remains protected for the long term.

Sustainable Material Options

Concerning the increasing global warming, people are rapidly moving towards sustainable packaging. It has now become a trend rather than a necessity. About half of the people in America are willing to pay more if the product has sustainable packaging. So, if you want to stand out in the market with your sales increased in a grid then there is no better option than sustainable and certified materials. Here are some benefits of using sustainable materials for packaging:

- Helps in decreasing waste generation

- Improvement of supply chain management

- Fosters customer loyalty

- Extended shelf life of product

- Reduced packaging damage

Closing Remarks

After reading all the durable material options and their need in product packaging you must have made mind to incorporate one of them in your packaging. Looking for an experienced packaging industry that provides quality materials at wholesale rates? CustomBoxesMarket is an ideal choice as we have decades of experience and provide versatile, cost-effective, and durable material options for customers. So look no further, because today is the right day to start your dream packaging!

Categories

Recent Posts

4 / March , 2026 Packaging Design

19 / February , 2026 Box Customization

16 / February , 2026 Box Material

3 / February , 2026 Gift Boxes

26 / January , 2026 Gift Boxes

6 / January , 2026 Sustainable Packaging

3 / December , 2025 Packaging Stats

17 / November , 2025 Custom Packaging

14 / November , 2025 Product By Industry

4 / November , 2025 Shipping Protection

28 / October , 2025 Custom Packaging

9 / October , 2025 Custom Packaging

7 / October , 2025 Shipping Protection

Get Free Quote

Related Products