An Ultimate Comprehensive Guide About Cornstarch Packaging

July 2, 2024 Box Material

In the current society where companies are professionals towards sustainability organizations globally are adjusting to green solutions.

One of the innovations is corn starch packaging which is used for attracting a lot of attention due to the possibility to eliminate the use of plastics as well as decrease carbon footprint.

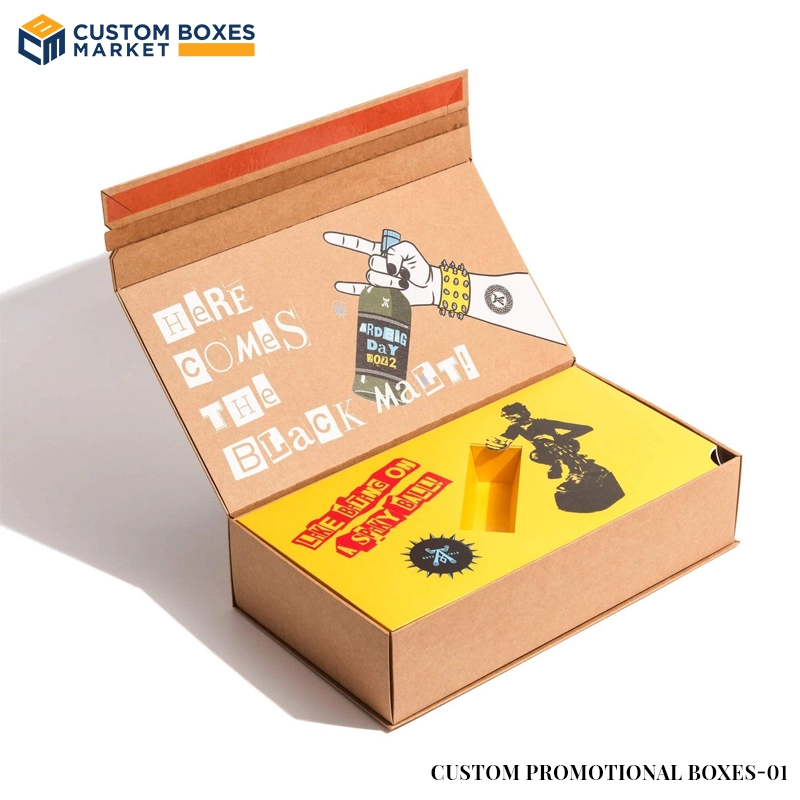

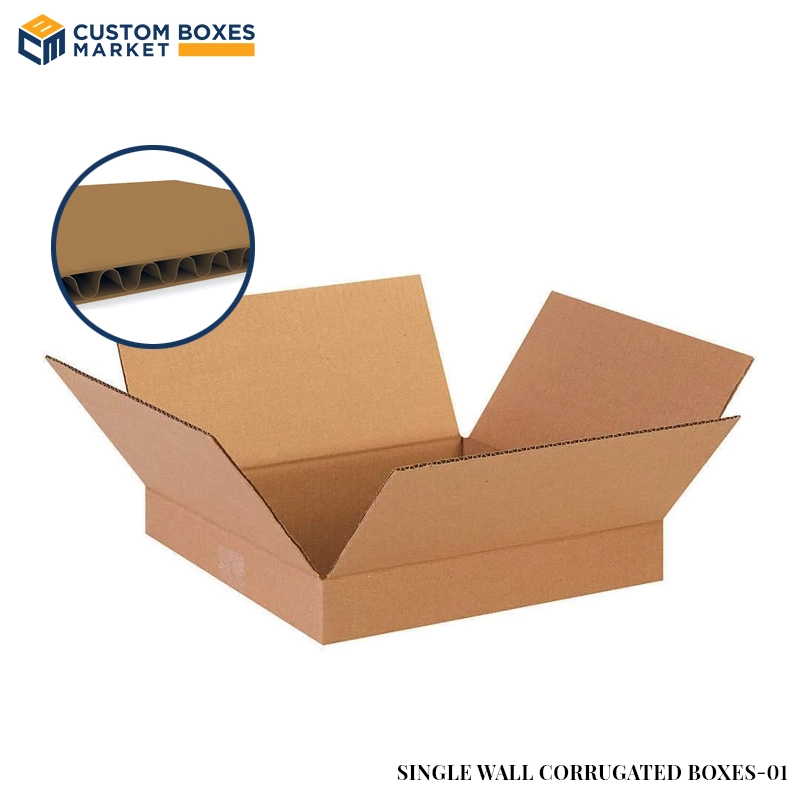

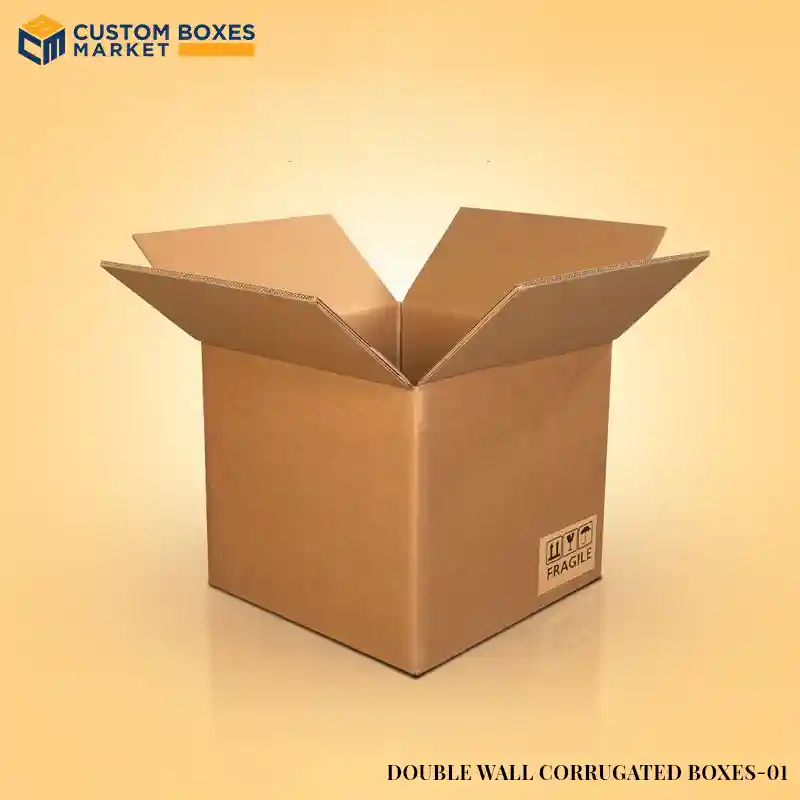

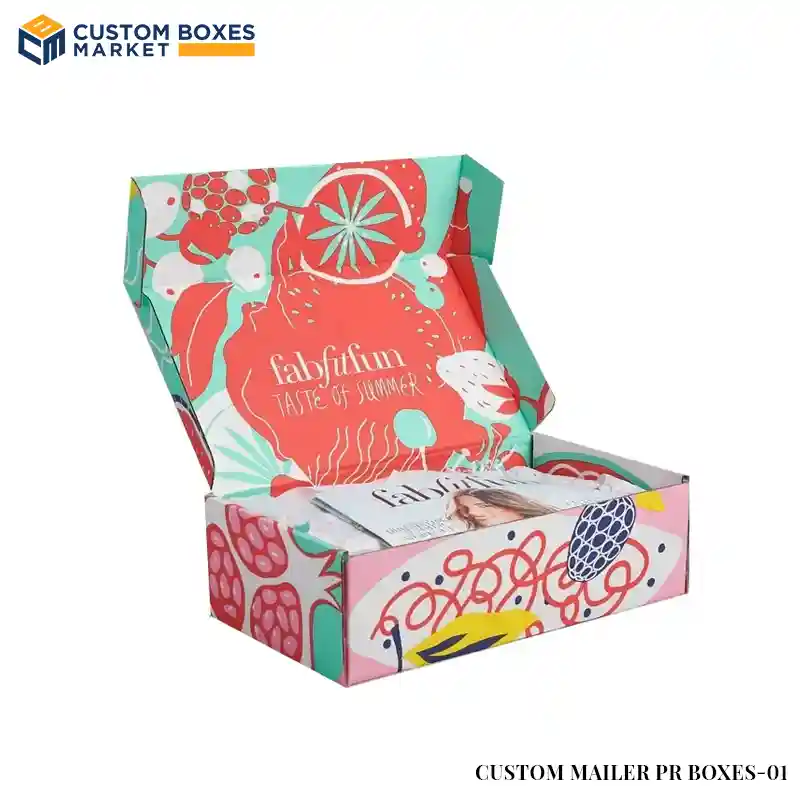

CBM offers the best packaging solution all over the USA and helps to elevate your brand identity and enhance your customer’s experience. We have thousands of satisfied customers who help to choose CBM for your packaging.

In this blog post, we will discuss starch packaging in terms of its advantages and fabrication uses along with the effect that it has on the environment.

What is Corn Starch Packaging?

Corn starch packaging also known as bioplastic is a type of plastic made from corn starch a recyclable and environmentally sensitive material.

While other plastics contain compounds derived from petroleum corn starch covering offers an environment-friendly solution that degrades when taken to the dustbin.

This type of packaging is in a category that goes by the name polylactic acid (PLA) it is made of plant material.

Benefits of Cornstarch Packaging

Biodegradable packaging is beneficial in many ways ecologically economical as well as healthier consumption. Here are the details of the following benefits.

Environmental Benefits

Biodegradability

Corn starch packaging is fully recyclable that is it decomposes into natural entities such as water carbon dioxide as well as compost if the conditions are favorable.

It also has some environmental benefits over using regular plastics that take hundreds of years to decompose and end up littering the environment in the form of waste.

Renewable Resource

This raw material is corn used to make the corn starch packages which is renewable in that it is termed as an annual crop.

This is inconvenient as compared to petroleum-based plastic which utilizes the limited reserves of fossil fuels.

Corn use also leads to decreased reliance on more scarce resources as well as supports agricultural renewability.

Reduced Carbon Footprint

Corn starch packaging made from corn starch production for instance produces comparatively lesser GHG emissions during manufacture than plastic.

Besides, growing corn also counteracts carbon emissions as the plant takes in carbon dioxide from the environment in the process of photosynthesis making carbon footprint small in the long run.

Economic Benefits

Job Creation

It is a proposal that may help in the generation of employment opportunities within the agricultural sector manufacturing sector along with composting companies that deal with corn starch packing.

Employment opportunities are also apparent through corn growing right from the farm starch production from corn along with packaging material production from corn-sourced starch.

Market Opportunities

The population is also increasingly concerned with the environmental impact of the products being used and therefore opts for green products.

They propose that companies that use corn starch packaging should do so to capture this market which will improve the company’s brand image by introducing products that are environmentally friendly according to the consumers.

As a result, there is the creation of a wide market base and expansion of a loyal client base.

Health and Safety Benefits

Non-Toxic and Safe

It is also not made from such dangerous compounds as Bisphenol A (BPA) and phthalates that are commonly used in making traditional plastics.

These chemicals can easily get into food and drinks, hence have various impacts on the health of people.

Corn starch packaging has more benefits than its polyethylene counterpart and is safer especially when used in packaging foods.

Allergen-Free

One has to look at the allergenic proteins that are compounded in corn the good news is that these proteins are eliminated during the processing of corn starch.

Therefore, the packaging material derived from corn starch is safe to use by those with corn allergies.

This makes it possible that mush packaging can be used in various packaging industries without any negative effect on the health of people.

Applications of Corn Starch Packaging

The best packaging is reusable hence it can be used in many fields and serves many purposes some of them listed below.

Food Packaging

PLA containers and films have been favored for enclosing fresh vegetables fruits as well as other perishables takeaway foods and disposable spatulas.

Medical Industry

Now, items like gloves and syringes used during surgeries can be made from corn starch material which is biodegradable.

Retail and E-commerce

Eco-friendly features of both shipping and product packaging allow companies to implement sustainable changes.

Advantages of Traditional Plastics

The social justice groups have long written off conventional plastics for being environmentally unfriendly but in this PEST.

Analysis The following benefits of traditional plastics should be mentioned Convenience- Durability and versatility.

Here are some key advantages of traditional plastics. Here are some key advantages of traditional plastics:

Versatility

The feature has capabilities to be molded into almost any shape and form giving traditional plastics flexibility of use across industries.

Whether in the packaging materials to automobile rims electronics buildings with construction use of plastics can not be surpassed.

Durability

Plastics are versatile and highly resilient attributes that define materials used in product applications that require high levels of durability.

This durability means that products manufactured from plastics have a longer service span and this in turn reduces the frequency of usage of the available products.

Lightweight

One of the major benefits of plastics is their lightweight as compared to many other materials that are used making them easier to transport and ship.

Little parceling of products decreases fuel usage during conveyance and so less emission of carbon monoxide.

Cost-Effectiveness

The following are some reasons why plastics are preferred among manufacturers over other materials Glass metals as well as paper are some of the materials that plastics compete with and most of the time plastics are cheaper to produce than these other materials.

This has been realized through affordability which has made these products popular in the manufacturing and packaging industries thus enhancing the prestige of cheaper consumer goods.

Chemical Resistance

Thus, I have come up with the following ideas plastics have good resistance to chemicals and water and thus can be used in the storage and transportation of various products including foods and medication.

This property aids in preserving the safety of the product from contamination and damaging factors.

Challenges and Limitations

Some issues and concerns associated with conventional plastics include Conventional plastic materials present several problems and drawbacks mainly due to their vulnerability to the environment.

Their biggest drawback however remains their ability to persist in the environment and hence pollute and bring harm to ecosystems in the long run.

Moreover, the manufacturing of conventional plastics involves the use of fossil fuels which increases the amount of carbon in the atmosphere and provides a further boost to the worsening climate change calamity.

The recycling rates of plastics are generally low owing to below-par recycling industries as well as low consciousness among the folks that leads to the accumulation of plastics into oceans and landfills.

In addition, small plastic particles or microplastics resulting from the degradation of large pieces of plastics within the ocean are also dangerous to the health of marine inhabitants and people.

The solutions to these challenges entail a collective endeavor toward the creation of sustainable substitutes as well as the implementation of better recycling structures and credible use and disposal protocols.

Future Outlook and Trends

Sustainable Packaging Solutions

Looking at the future outcomes of the next steps in packaging it can be seen the main direction is towards material optimization.

We are witnessing a shift in consumer desire for green packaging over plastic and foils resulting in improved bioplastics bio-degradable packaging and reusable packaging solutions.

Market forces are demanding green products in terms of packaging and therefore there has been an emergence of business organizations aiming at researching and developing ways of coming up with packaging that is environmentally friendly at every point of the product life cycle.

Technological Integration for Waste Management:

The following paper will present an overview of how technology is going to shape the future, especially regarding waste and more specifically plastics.

AI and ML-driven technologies enhanced sensor sorting as well as recycling technologies and plastic waste management.

Advanced and efficient waste management systems that collect data through sensors help to plan the smarter route for waste collection decreasing the levels of contamination in recycling and increasing the recycling yield respectively.

Governments and industries focus on environmental and green agenda issues such as the reduction of waste and implementation of the circular economy.

Conclusion

At CustomBoxesMarket, our corn starch packaging provides an effective and viable solution to the environmental woes of the conventional polymers currently on the market.

Since this can be composted easily, it is considered a better substitute for many industries in the present and future.

It is currently being faced with several challenges some of which are the cost of utilizing the technology and the durability of the products made from the material nevertheless ongoing innovations and higher consumer demand for the technology are encouraging its use.

Here, in adopting CBM packaging and other related solutions we are part of the collective journey to start gradually cutting down on non-biodegradable plastics and making this world a much healthier place for every one of us and all future generations to come.

Categories

Recent Posts

19 / February , 2026 Box Customization

16 / February , 2026 Box Material

3 / February , 2026 Gift Boxes

26 / January , 2026 Gift Boxes

6 / January , 2026 Sustainable Packaging

3 / December , 2025 Packaging Stats

17 / November , 2025 Custom Packaging

14 / November , 2025 Product By Industry

4 / November , 2025 Shipping Protection

28 / October , 2025 Custom Packaging

9 / October , 2025 Custom Packaging

7 / October , 2025 Shipping Protection

24 / September , 2025 Custom Packaging

Get Free Quote

Related Products