Answers About Box of Cereal Dimensions, Measurements of a Cereal Box & More!

February 20, 2024 Box Customization

Are you running a food manufacturing industry? Do you want to know how to get the dimensions of a cereal box? If your answer is yes then we at CBM are ready to help. We understand that measuring the size of the boxes is a difficult but necessary task as a perfect box can be achieved when it has the perfect dimensions.

Measurement of a cereal box is an arduous task as it requires expertise. Nonetheless knowing this information tells us how much cereal is in a box we can add. In this blog, we will let you know the best strategies using which you can measure your boxes with ease, so let’s read the blog!

Why Is It Necessary To Measure A Box?

The measurement of boxes is very important if you want to get the perfect box that can flawlessly pack your products and keep them fresh. Cereals have a long shelf life which means that they can be stored for a long duration. One thing that makes the storage of cereal pretty difficult is that they are liable to get broken.

Understanding how to take cereal box dimensions helps brands to give perfect protection to the cereals. You can deliver your cereals without any damage and inspire the customers with your professional presentation of products. So if you want to make a marvelous impression on the customers by keeping your cereal texture then it is mandatory to understand the dynamics of the box measurement.

Tips To Measure Cereal Box

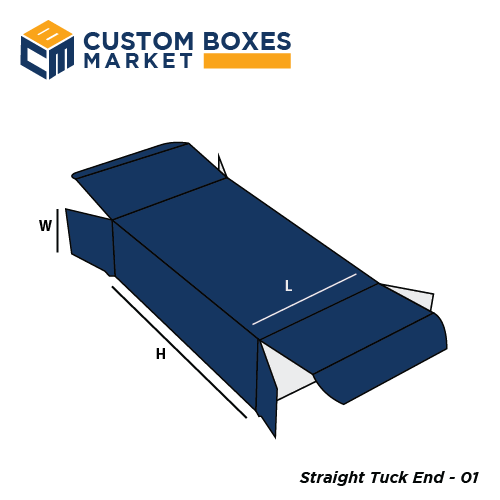

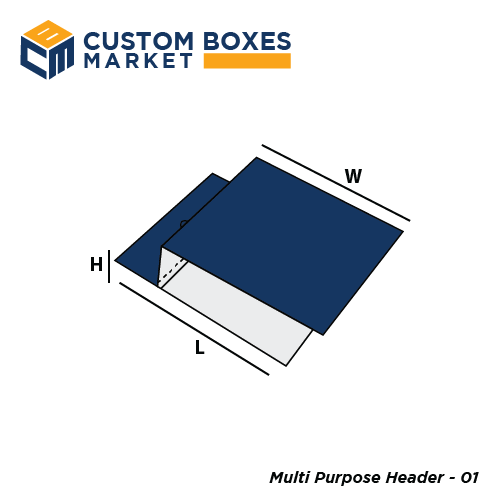

If you want to know how tall a cereal box, or how much its width is, then you have to open the box in a flat position. Spread your box flatly on a plain surface to take measurements. You need a ruler or a measuring tape to take the calculations precisely. Follow the below-mentioned steps and take the calculations accordingly:

Box Thickness

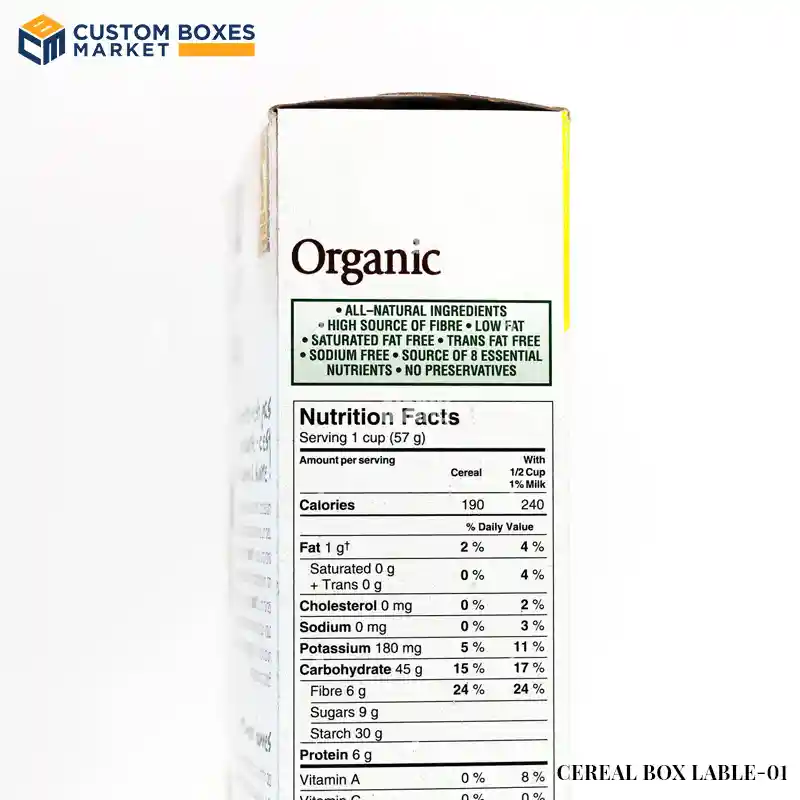

The first thing that we do while manufacturing boxes is the selection of materials of our required thickness. On average, a cereal box has a thickness of 0.022 inches. Nonetheless, it depends upon the material that you select. The actual thickness of the boxes can be measured only by the material seller. However, for specific requirements, you can get the custom option for material thickness. Generally, materials in the following thicknesses are available:

- Cardboard is available in 0.188 inches

- The thickness of corrugated material depends upon the middle layer inside the box and that is:

- A flute is 0.19 inches

- B flute is of 0.125 thickness

- C flute is of 0.15 thickness

- D flute is of 0.085

- E flute is of 0.059 inches

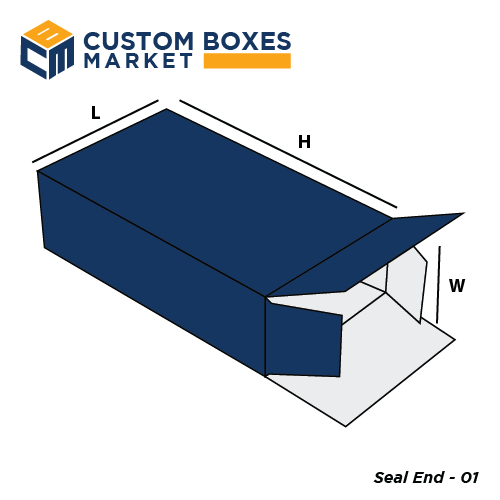

Measurement Of Width

The width of the boxes is also based on the choice and preferences of the companies and the portion size they are going to pack into the boxes. On average a custom cereal box has a width of almost 2 inches. To measure the width you have to place the ruler or your measuring tape at a right angle to the length of the box.

Length Calculation

To calculate your box length, place the flattened box on a plain surface, take your ruler, and place it at the front border of the box. On average a family pack is 7.5 inches in length. So if your portion size is smaller or larger than the measured box you can increase the inches accordingly.

Height Calculation

To calculate how tall is a box of cereal you have to calculate the height of the boxes. For this, place the ruler on the longest side of the box and take the measurement. Most companies choose 12 inches as the standard size for their cereal boxes but as you are going for custom boxes you can select any size that your product requires.

Volume Calculation

To calculate the volume of the boxes, you have to multiply the width, length, and height of the boxes. Box volumes also are selected according to the portion size of the cereals. By knowing how many servings you are going to sell you can identify what should be the volume of your packaging.

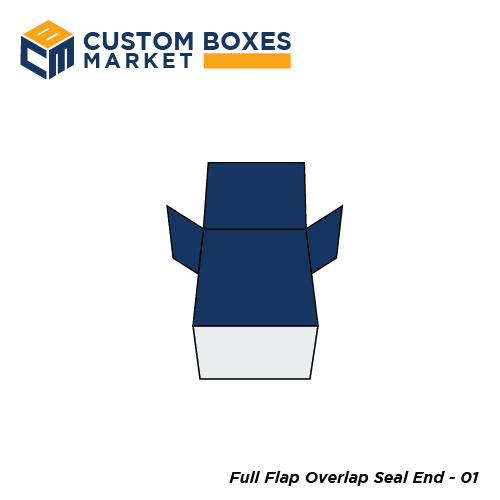

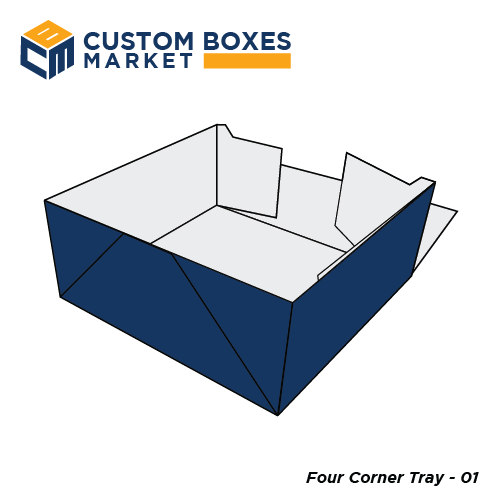

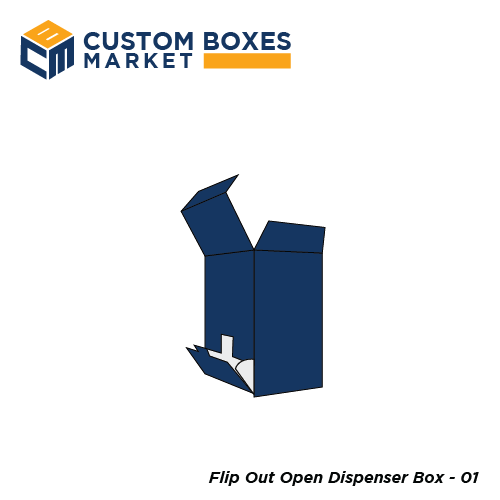

How Custom Cereal Boxes Are Manufactured?

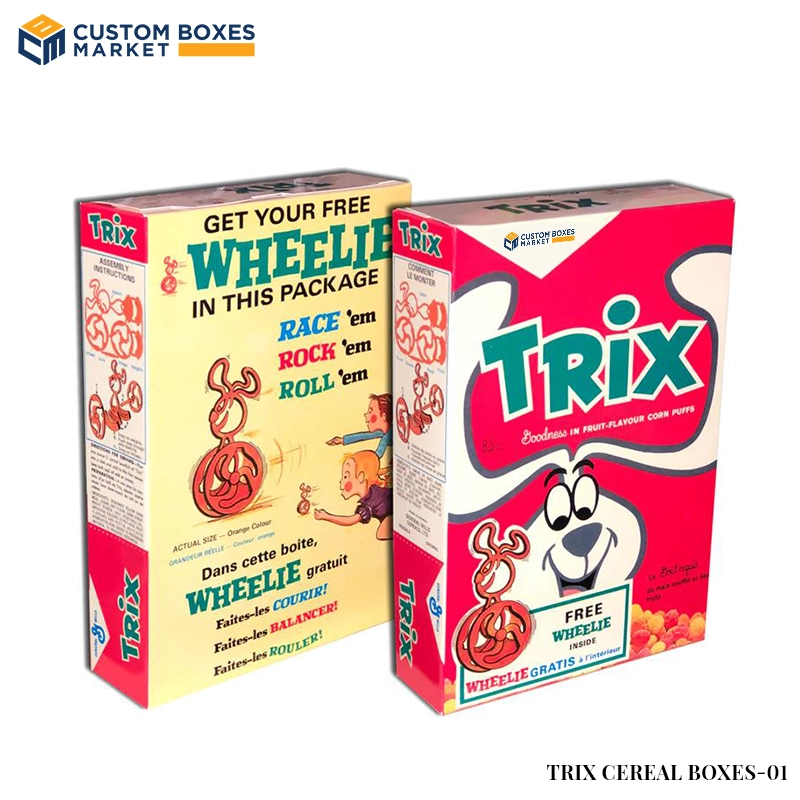

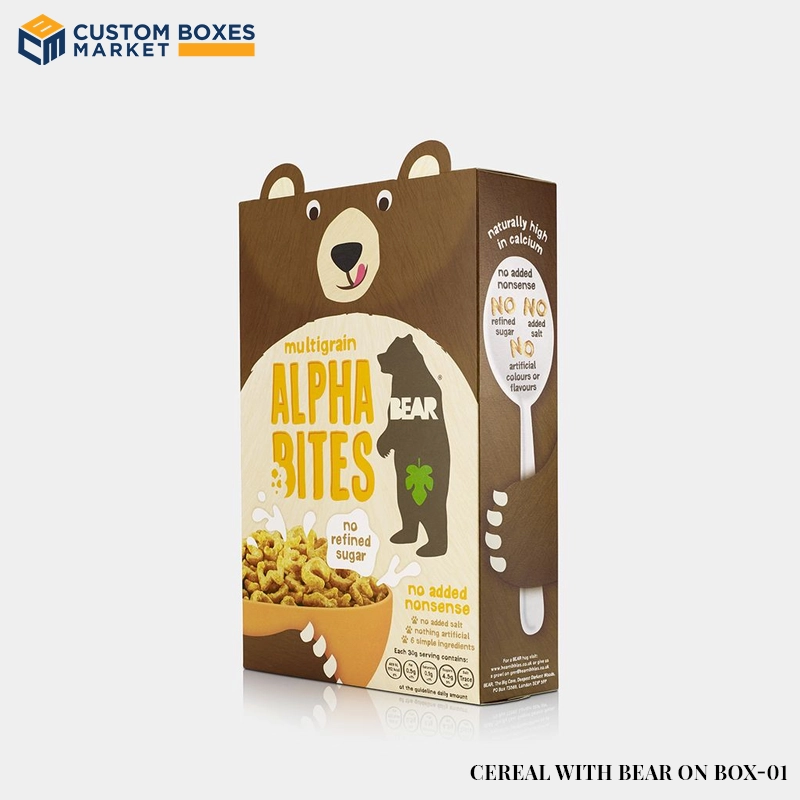

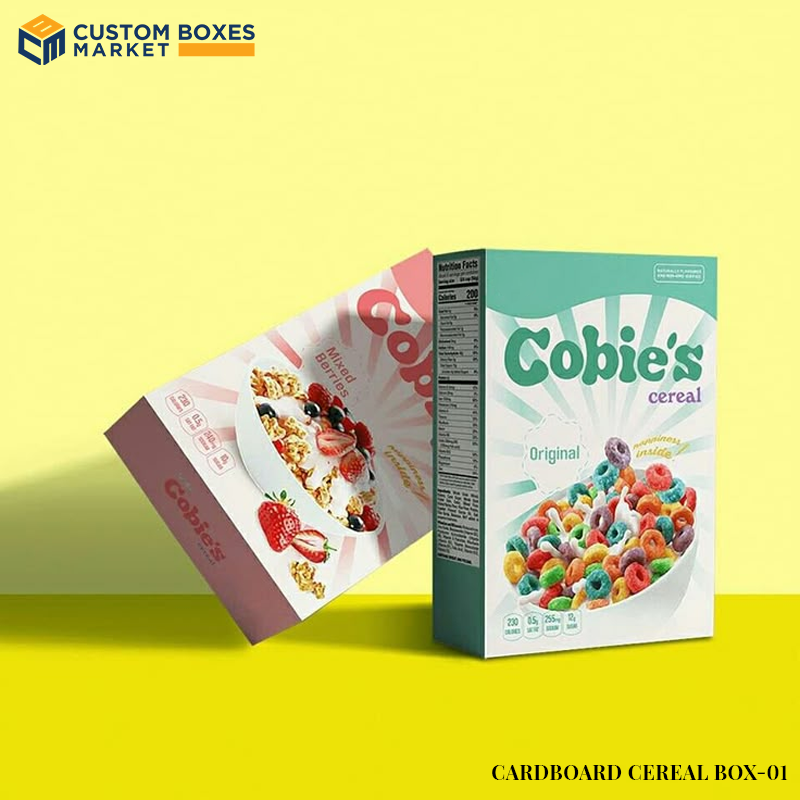

After understanding the tips to measure the boxes you certainly are interested in identifying how the boxes are manufactured. As a renowned packaging industry in the USA, we at CBM make the boxes using quality material and updated methods. Apart from this, we have the option of food-grade material that is an ideal choice for food boxes such as fast food packaging, muffin boxes, cereal boxes, etc.

We manufacture the boxes following the below-mentioned steps:

-

Materials Selection

The first step in the manufacturing of the boxes is the use of material selection. The material must be of the best quality so that your cereals do not get soggy that is why we at CBM use kraft, cardboard, and corrugated material. Our kraft material is 100 % organic so if your focus is on organic cereals that are minimally processed then you can go with kraft material.

On the other hand, if you want your packaging to look catchy then the material can be corrugated or cardboard. Both the materials differ in the fact that the corrugated one has internal flutes but the cardboard does not.

-

Printings

For customized cereal packaging boxes we have the top three printing methods. The printings on the boxes allow you to demonstrate what are the best qualities of your cereals and how they are better than the rest of the brands. You can also get a logo-printed cereal box that will allow you to get a free-of-cost promotional tool.

-

Customized Designing

Every brand uses printings and the best of the available materials to manufacture tier custom boxes. Nonetheless, one thing that will make your brand outshine the others is the use of add-ons. The main purpose of add-ons or embellishments is to make the boxes attractive so that when the customers enter the shop they immediately note your product.

Add-ons can be used to make the typography on the boxes more pronounced or they can be used on the boxes to make boxes elegant. By contacting CBM to get your boxes you can get a lot of add-on options that will make it easy for you to design your boxes.

-

Coatings

The last thing that is mandatory to make the boxes perfect is the application of coatings. Pre and post printing coatings both are required on the boxes so that the material remains scuff-free and smooth. The post-printing coating enhances the look of the boxes by giving them an elegant matte shiny touch that entices the customers and also gives stretch to the boxes.

Final Words!

By measuring the dimensions of a cereal box you can get to know what is the best size of your box. For your custom cereal boxes, you just have to follow the simple steps that are mentioned in the blog. After knowing the perfect size of the box you can make the changes in your box dimensions as per your requirement. With the free of cost consultation of our company and lower rates you can get your dream packaging easily.

Also Read: https://customboxesmarket.com/reputation-reasons-for-custom-cereal-boxes/

Categories

Recent Posts

4 / March , 2026 Packaging Design

19 / February , 2026 Box Customization

16 / February , 2026 Box Material

3 / February , 2026 Gift Boxes

26 / January , 2026 Gift Boxes

6 / January , 2026 Sustainable Packaging

3 / December , 2025 Packaging Stats

17 / November , 2025 Custom Packaging

14 / November , 2025 Product By Industry

4 / November , 2025 Shipping Protection

28 / October , 2025 Custom Packaging

9 / October , 2025 Custom Packaging

7 / October , 2025 Shipping Protection

Get Free Quote

Related Products