Frozen Food Packaging Trends You Need to Know in 2025

September 5, 2025 Inspiration

“According to Fortune Business Insights, the global custom frozen food packaging market is expected to gain 11.95$ billion in 2025!”

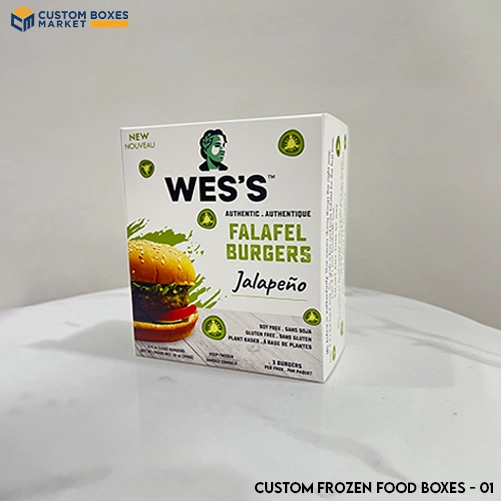

Frozen food packaging is gaining momentum as more people want ready-to-eat food products in the U.S. Grocery and general stores are actively stocking bags containing frozen meat, seafood, bakery items, fruits, vegetables, and even appetizers.

Businesses dealing in custom frozen food boxes are also experiencing a boon period this year. The competition is heating up to see which brand makes it to the top line of providing the most qualitative and safe packaging to their customers.

Regardless, the key concern is, can your packaging business benefit from it? To answer this question, we will walk you through some of the most popular frozen food packaging boxes trends you need to follow right now in 2025!

The Frozen Food Packaging Trends of 2025

In 2025, manufacturing trends are shifting towards a more consumer-centric approach to gain mutual benefit and develop a long-term and sustainable relationship. Frozen boxes are made keeping in mind what buyers are ready to preserve in their freezers.

Here, we will list the seven most recently popular trends being incorporated by the custom frozen food boxes by suppliers.

1: Sustainability Preserved with Biodegradable Alternatives

Biodegradable food packages are generally high-performing on a global level. The public prefers their boxes to be safe when frozen at higher temperatures and disposed of with negligible carbon footprints, the qualities severely lacking in regular plastic bags.

Environmental degradation is becoming a major threat to both land and marine ecosystems, and the activists are actively educating its adverse impacts to common people. The paper and cardboard are replacing plastic to facilitate sustainable disposal practices.

So, to get ahead in your frozen food packaging, choose boxes containing biodegradable alternatives like bioplastics or starch-blended films.

2: Increased Use of Recyclable Packages

Under the umbrella of sustainable development goals, recyclable packages are second in line to biodegradable packages for excessive waste control. This trend is not widely applied yet, but it is truly popular to implement a consumer-centric approach.

Reasons surrounding its rare applicability stem from the bag’s material composition, with a blend of paperboard and polyethylene.

How to check if the Box is Recyclable?

The customers buying custom frozen food boxes can inspect the bags’ recyclability by doing the following:

- Look for a ‘recyclable’ or related label.

- Visit the box’s selling website

- Communicate with the customer support team

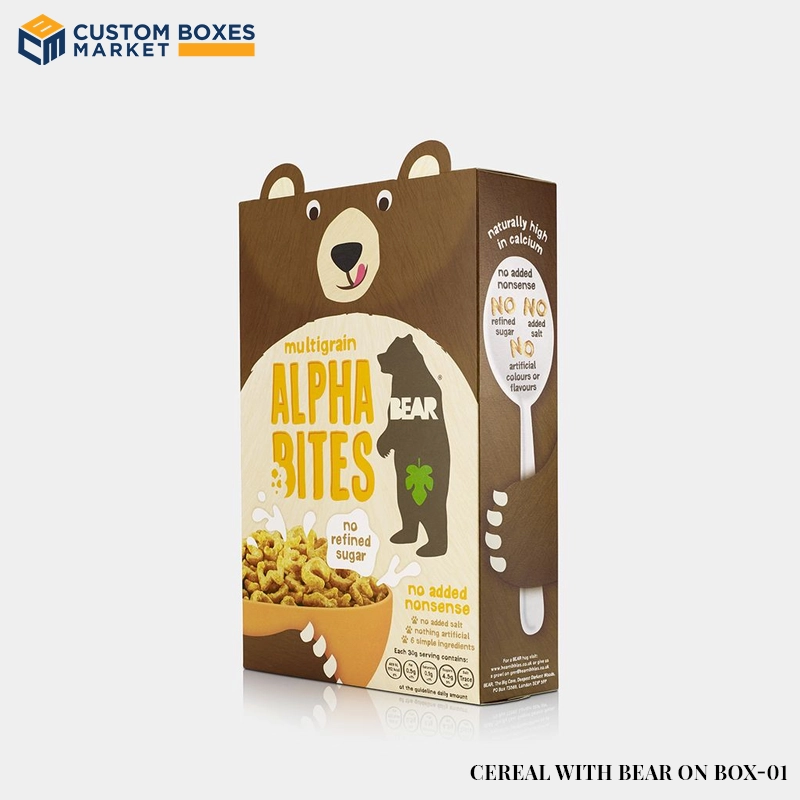

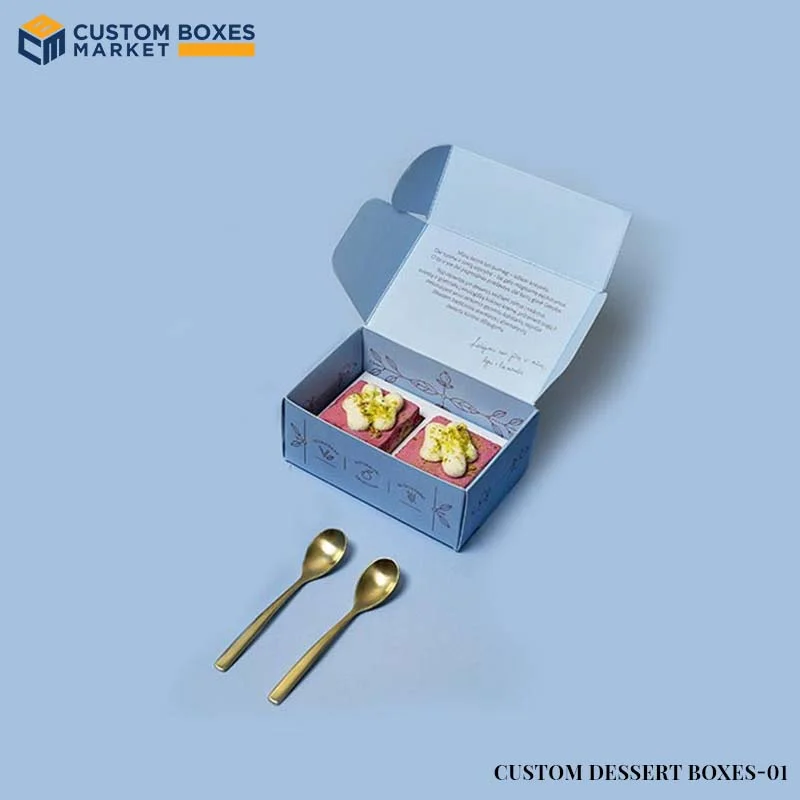

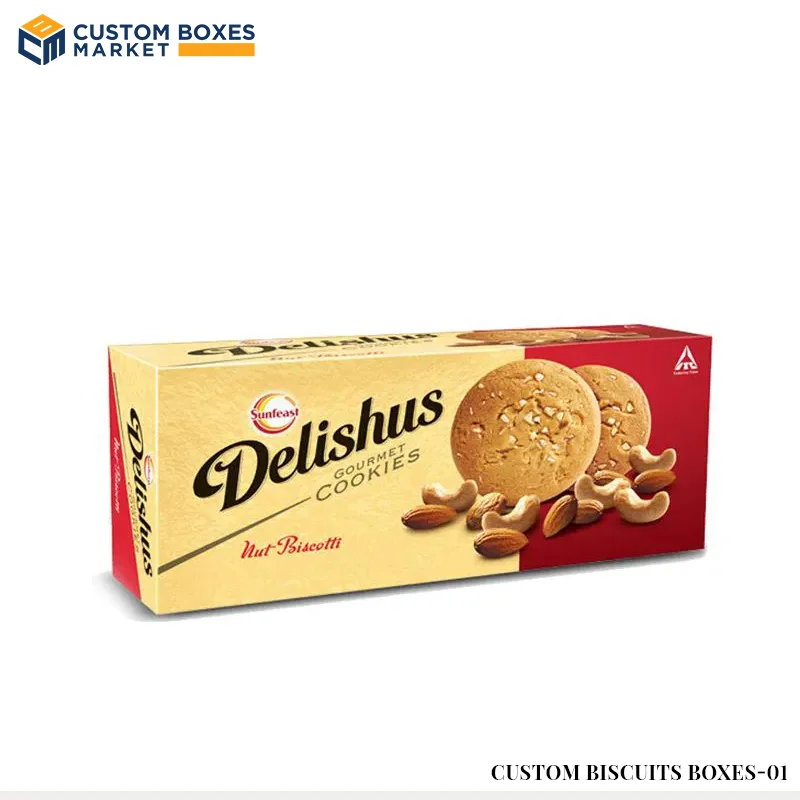

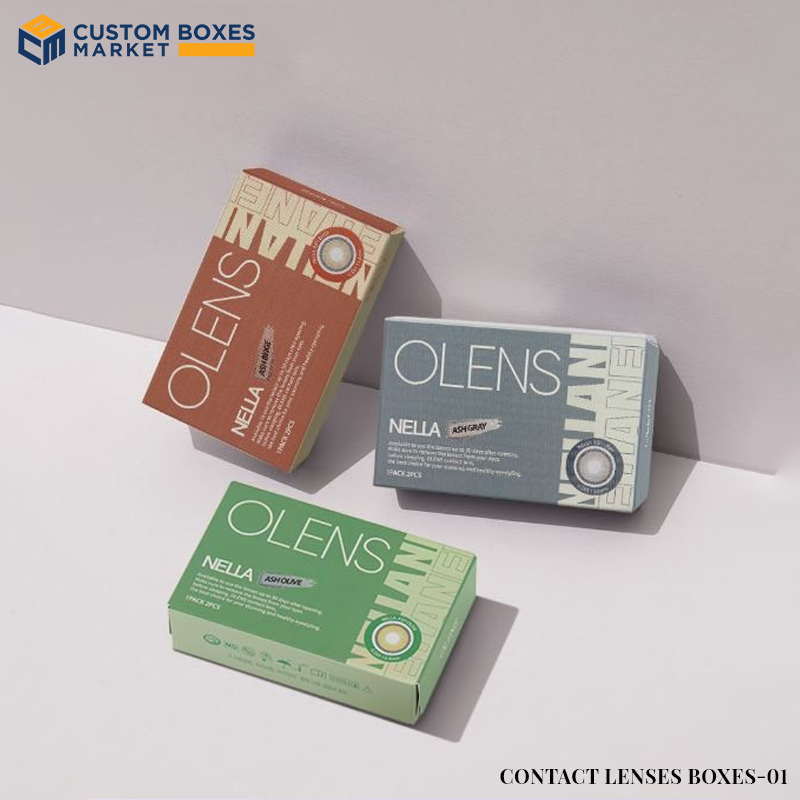

3: Designs are Now More Important

Imagine designing an ice cream cone sleeve with non-printed paper and a poorly designed hollow cone with dimensions. That would probably be the end of that business.

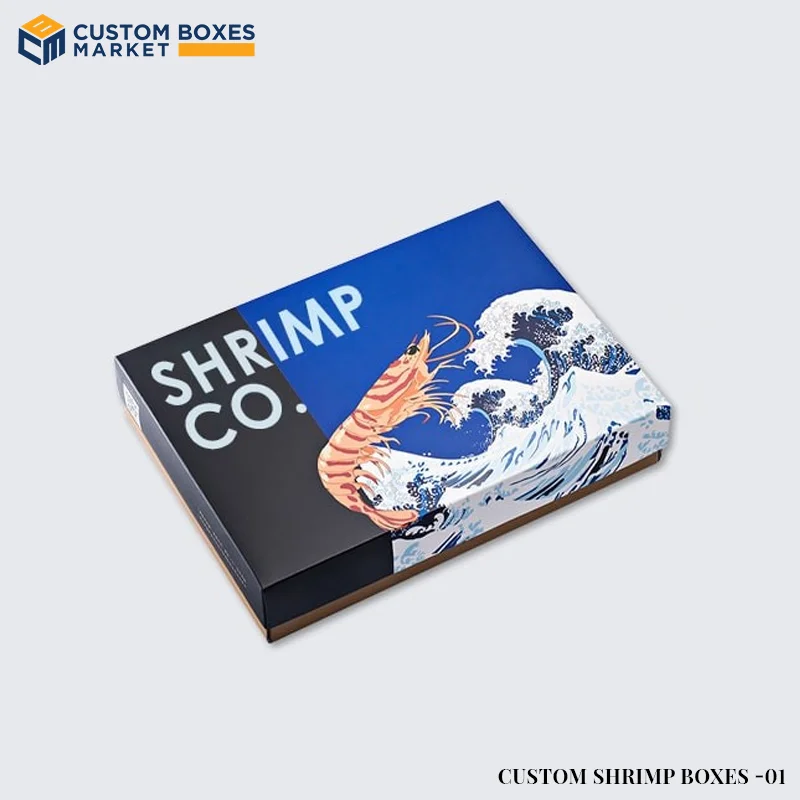

Designs are meant to increase customer engagement by including images or logos that resonate the most with your product and the audience. Some packaging companies even include a favorite character or print ISO standard logos to impress and urge consumers to buy their frozen food packages.

Another interesting observation is how most buyers associate good design with high quality of the box. With each carefully selected design element, you share a story and the authenticity of your brand and turn each new customer into a regular or bulk buyer.

4: Visually Appealing Infographics

Printing suitably attractive illustrations or infographics helps convince the purchaser to make swift and informed decisions. These days, the packaging companies use various printing and coating methods, like:

- Digital printing

- Screen printing

- Rotogravure Printing

- Lithography

- Flexography

The printing method is decided keeping in view the material type, temperature effects (freezing), and food safety from the ink. Take custom frozen pizza boxes as an example, where you would want bold mono-colors like yellow or red to improve shelf-appeal for their fast food lovers.

5: Advanced barrier Protection with Smart Technology

Innovations in technology are providing easier solutions to achieve superior barrier protection for frozen items. These barriers even help keep the food fresh and tasty for much longer than the bag’s original capacity by introducing new films that prevent freezer burns.

Recently Modified Atmosphere Packaging (MAP) is being implemented for the preservation of frozen meals. In this type of packaging, the gases inside the box maintain quality by controlling spoilage and keeping the ready-to-eat food tightly sealed.

In interesting fact regarding frozen food is that it is usually kept in low-oxygen packaging, but MAP seals these items within a high-oxygen environment, increasing their shelf life.

6: Resealable and Microwaved Packages on the Rise

Most frozen ready-to-eat customers lead busy lives and demand easy solutions by heating up their meal in the microwave along with the custom box. For this class of society, the custom packaging industry is manufacturing boxes that are microwave-safe for quick consumption.

Alternatively, this same class of consumers also sometimes prefer resealable bags or pouches for gradual food consumption and keeping the leftovers fresh. The resealable bags can reduce food waste and improve the durability of your frozen food packaging products.

Available Custom Resealable Frozen Food Bags in the Market

Currently, you can buy your resealable bag to store frozen items from the following list around the U.S:

- Cardboard boxes

- Mylar bags

- Stand-up or Lay-flat pouches

- Flange and Slider zipper bags

7: Incorporation of Anti-fog Materials

Exposure to moist air spoils frozen food at an accelerated rate and degrades the insides of the box. For preventing fog formation as a mitigatory measure, anti-fog materials and coatings are used during the custom frozen food packaging process.

The anti-fog materials include:

- Coated Natural Kraft (CNK) paperboard

- Solid Bleached Sulfate (SBS) paperboard

- Clay Coated Newsback (CCN) paperboard

- Wax-coated cardboard

In coating and additives, you can select from the following options:

- Glycerol or Sorbitan esters with plastic resins

- External plastic films

- NANOMYTE SAF-100

What Next?

Keeping in mind the above frozen food packaging trends of 2025, implement the incorporation of a consumer-centric approach in your packaging niche ultimate strategy. Use highly durable materials customized using smart technologies such as MAP or quick QR codes on each box.

Finding the best frozen food box suppliers is hard, but Custom Boxes Market is here to help you unlock all of the above premium features at exceptionally cheaper rates. We guarantee that each of our package are developed using sustainable means and materials while allowing our clients freedom to choose over any customization for their brand.

The year 2025 just might be the best time to start your own food packaging business!

FAQs:

Q: What material is best for customizing a package for frozen food items?

You can use an anti-fog material such as CNK or SBS paperboards with durable pre- and post-coatings to sustain frozen food for longer durations.

Q: Is custom frozen food packaging good for smaller businesses?

Small businesses can invest in setting up to-go shops or door-to-door delivery for frozen food items. Many office workers prefer their food to be ready-to-eat in frozen food boxes.

Q: Can I buy custom frozen food boxes wholesale online?

Yes, the customized frozen food boxes can be ordered online wholesale. To get the most out of it, look for perks such as free shipping in bulk or free online design support.

Q: Which size should I go for for my frozen food products?

Custom-made boxes for frozen items have different shapes and sizes depending on the product they needs to carry and how long that product needs to be preserved. Based on the type of food you are selling, consult the frozen bag size charts.

Q: Does custom packaging usually affect the shelf life and storage requirements of frozen foods?

The personalized bags are made from vastly durable and sustainable materials, unlike normal food boxes, which directly affect and enhance the shelf life and storage requirements of frozen products.

Categories

Recent Posts

19 / February , 2026 Box Customization

16 / February , 2026 Box Material

3 / February , 2026 Gift Boxes

26 / January , 2026 Gift Boxes

6 / January , 2026 Sustainable Packaging

3 / December , 2025 Packaging Stats

17 / November , 2025 Custom Packaging

14 / November , 2025 Product By Industry

4 / November , 2025 Shipping Protection

28 / October , 2025 Custom Packaging

9 / October , 2025 Custom Packaging

7 / October , 2025 Shipping Protection

24 / September , 2025 Custom Packaging

Get Free Quote

Related Products