What is a Dieline? How to Make a Dieline for Packaging and Printing

May 27, 2024 Box Customization

In the packaging industry, the precision of the dimensions and the professional look of the box depends upon the dieline. Dielines can be considered a blueprint that is used in the packaging and printing industry to get a template for custom boxes.

The layout and cutting of a packaging material is one of the most important parts of quality packaging. No brand wants to get either a large or a small box compared to its products, to make sure that our customers get the perfect and impeccable packaging from us we use one of the most cutting-edge technologies to create die lines.

If you want the digital mockup of your packaging to perfectly translate into the physical custom packaging boxes then you must understand dielines. However, it is a task that must be left to professionals like CustomBoxesMarket, but for a basic understanding, this blog can be a very useful piece of writing for you. So let’s get started!

What is a Dieline?

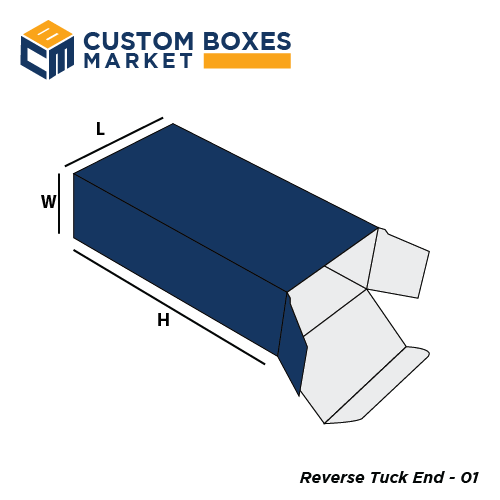

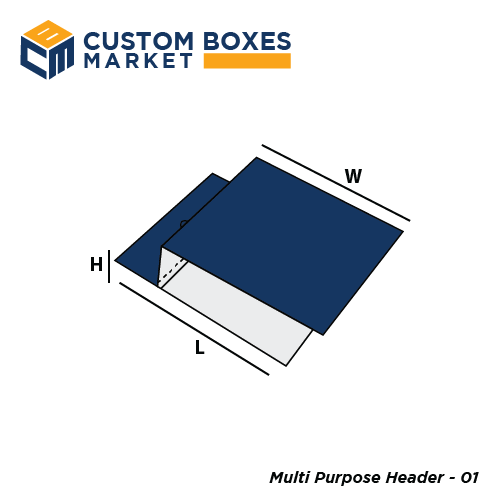

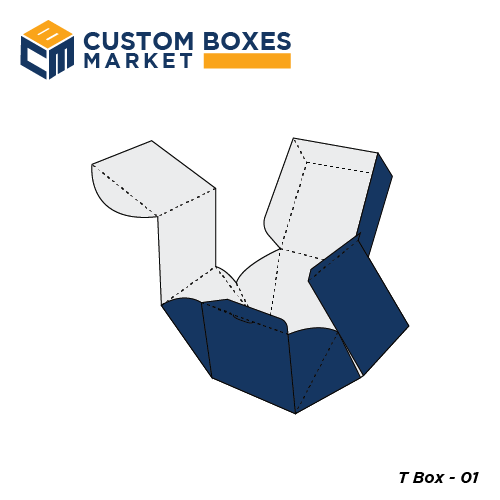

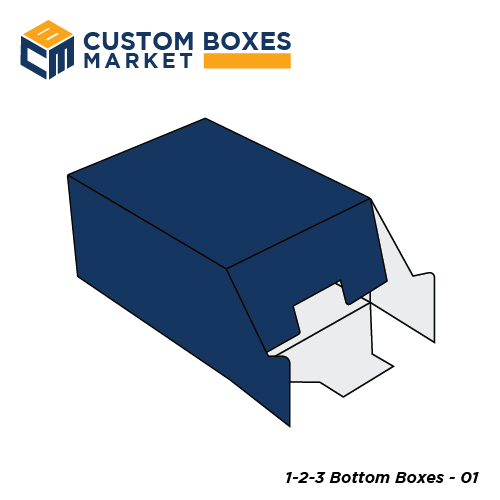

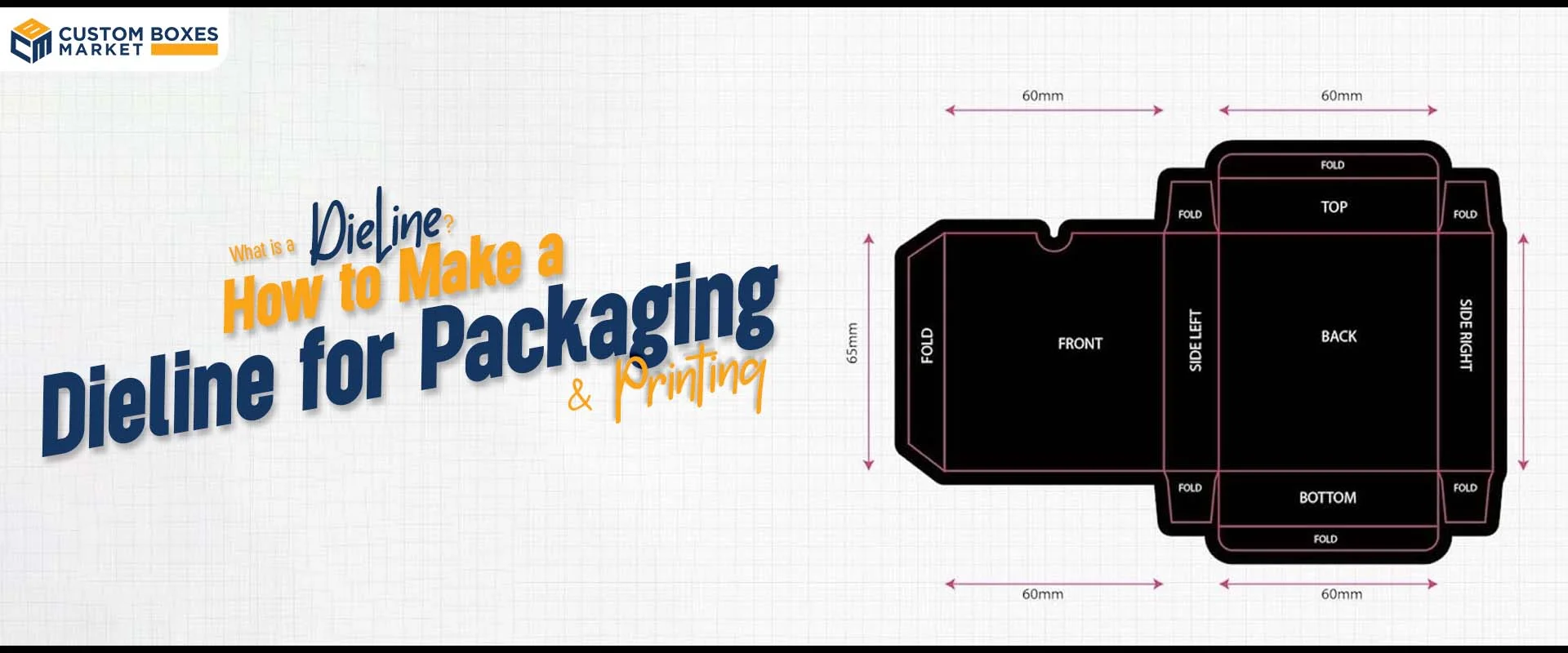

In simple words, we can say that a die line is a technical diagram of your boxes that consists of mainly five parts namely, cut lines, safety margin, perforation lines, fold lines, and bleed areas. It is a kind of guideline for the box manufacturers that lets them know where to cut, crease, or perforate the material. The shape and structure of your final packaging depend largely on dieline. Let’s first understand the five different parts of dieline:

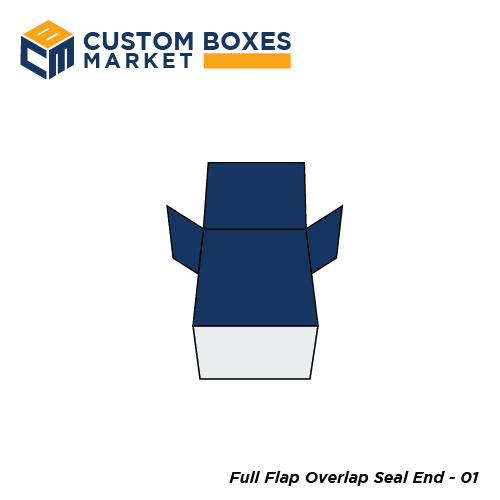

- Cut Lines (Solid Lines): Cut lines show the exact areas from where we have to cut the material to form a specific shape, such as a pyramid box

- Fold Lines (Dashed Lines): Fold lines are the areas that are marked to ensure the correct folds of the packaging during assembly

- Bleed Area: The bleed area is marked outside the outlines and it extends beyond the final size of the box. These lines are used to ensure the prevention of white edges after cutting. So if any minor misalignments occurred during the time of cutting, the bleed area accommodates that

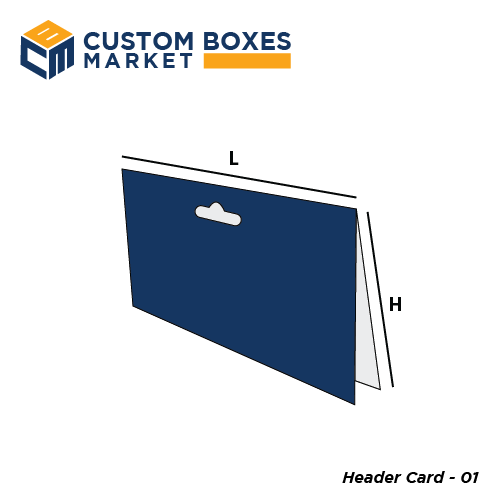

- Safety Margins: These are the boundaries within which we have to contain our design elements such as text, logos, or any other graphic image

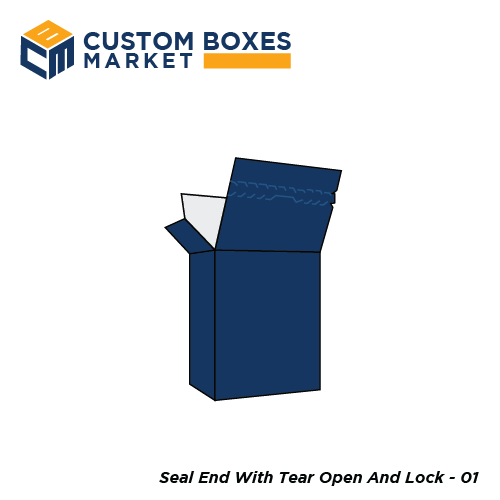

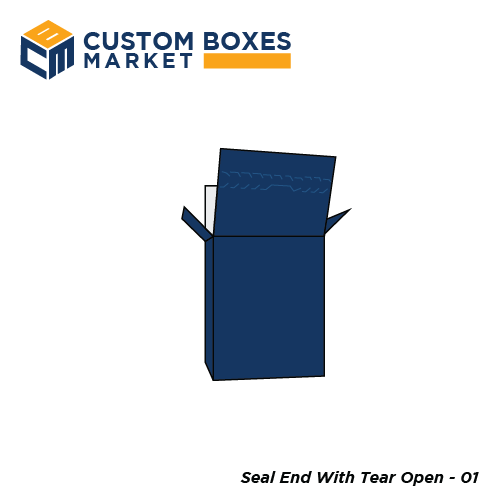

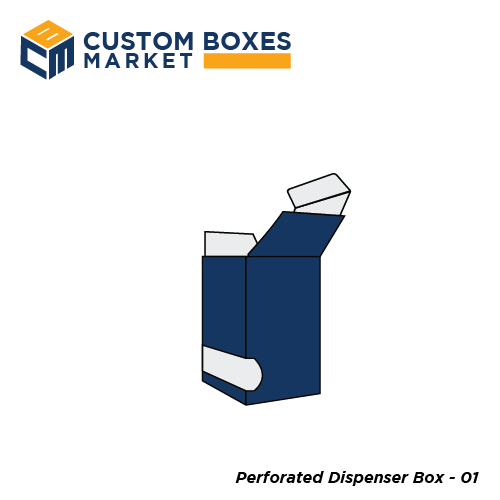

- Perforation Lines (Dotted Lines): These lines are an additional element of the dieline that is added when a section of the packaging is required to be tear-off, for instance, in tear-off coupons, easy-to-open boxes, etc.

How to Make a Dieline for Packaging and Printing

The creation of dieline is a task that can be done only by professionals and there are several reasons for this such as to ensure precision, for safety purposes, and to avoid any kind of material loss. There are several steps involved in the creation of a dieline including the use of software and the finalization of the template via machine cutting:

Understand the Product and Packaging Requirements

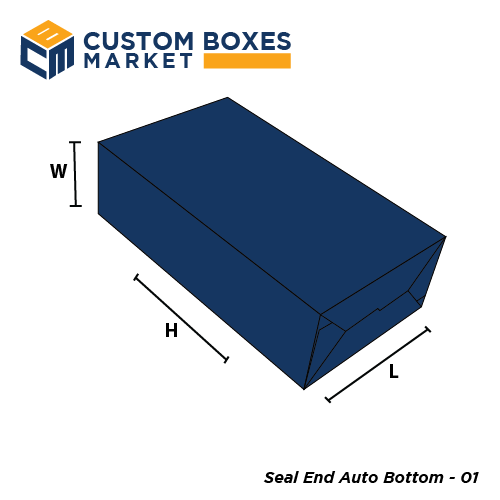

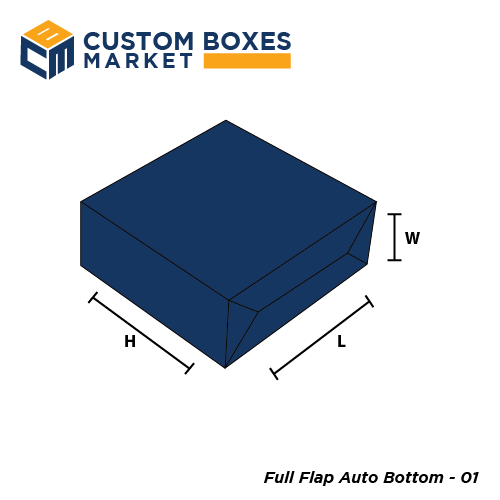

If you are going to create a dieline then you have to get a basic understanding of your box dimensions and product packaging requirements. This is essential if a manufacturer wants to give error-free packaging to its customers. The following things are required for this precision:

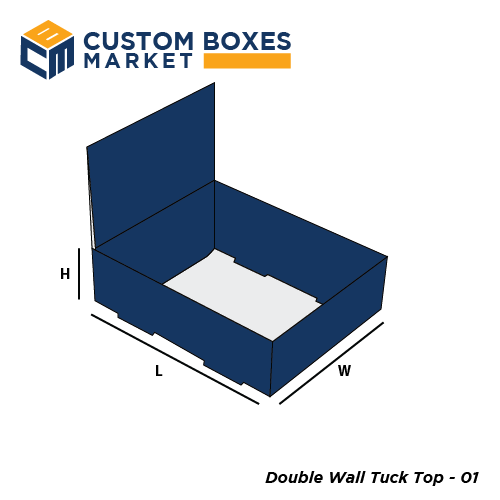

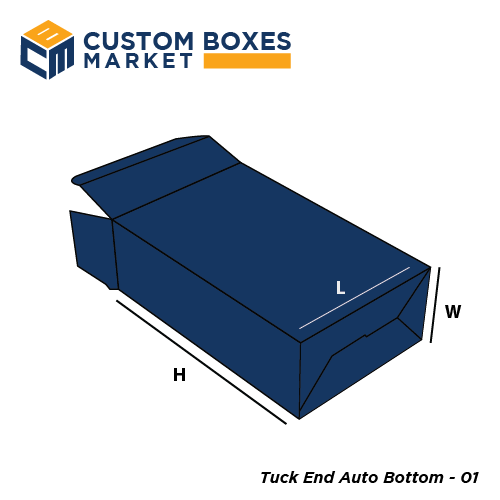

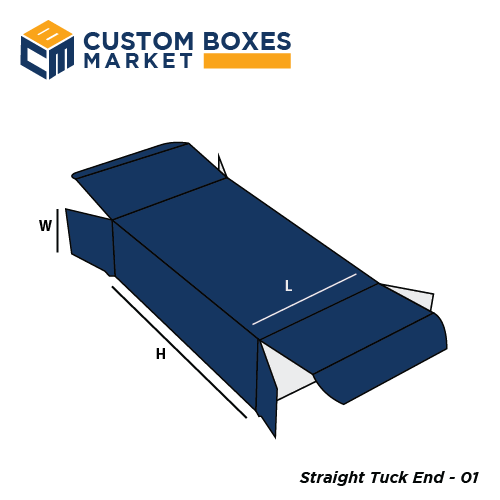

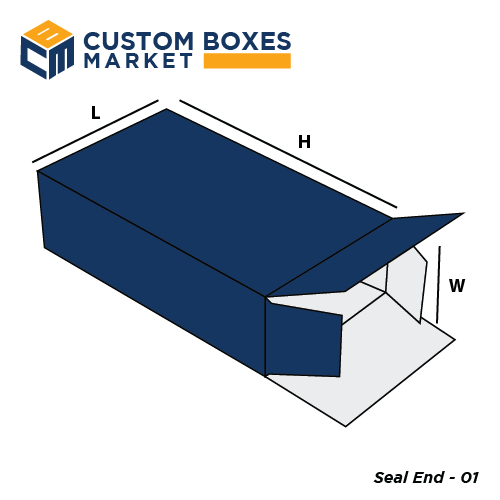

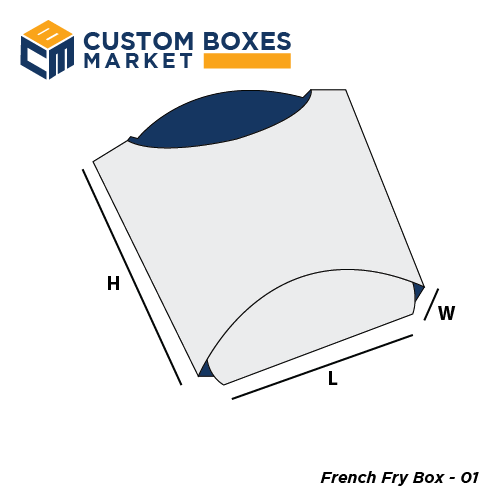

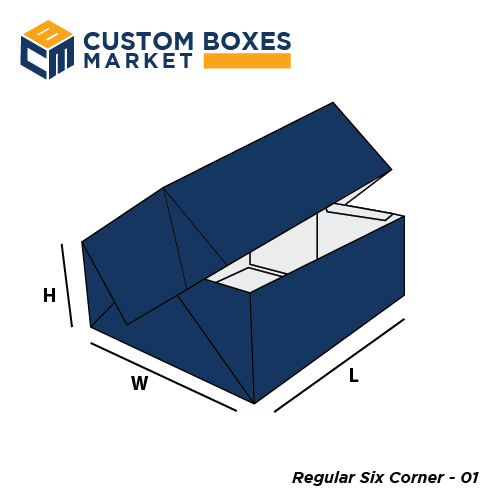

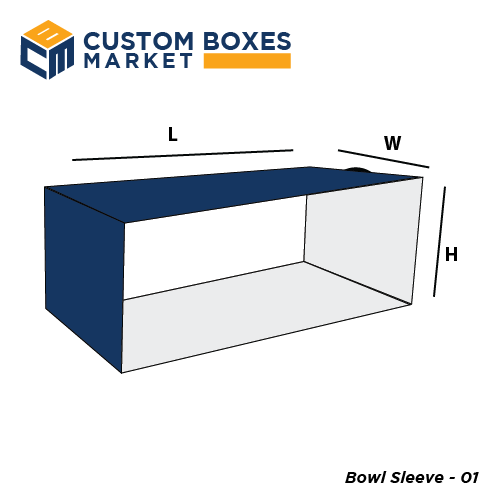

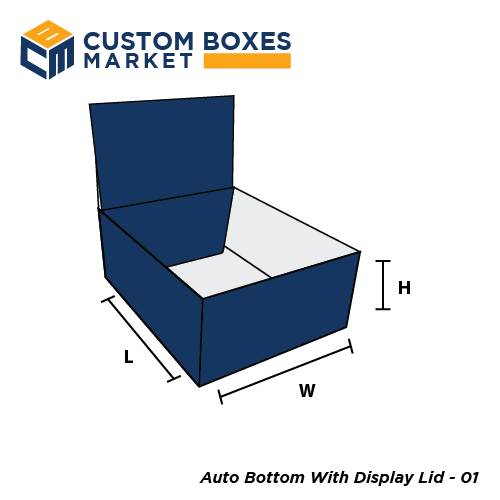

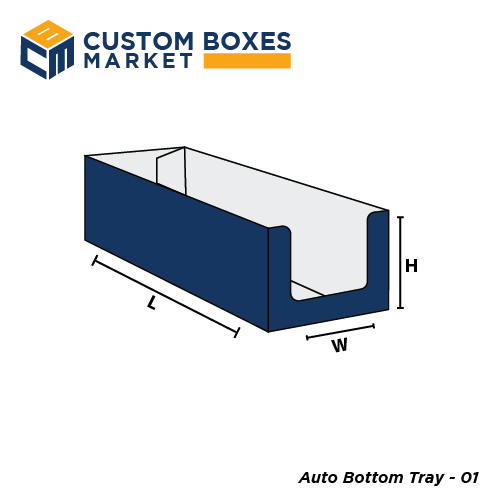

- Product Size And Shape: Height, length, and width of the boxes

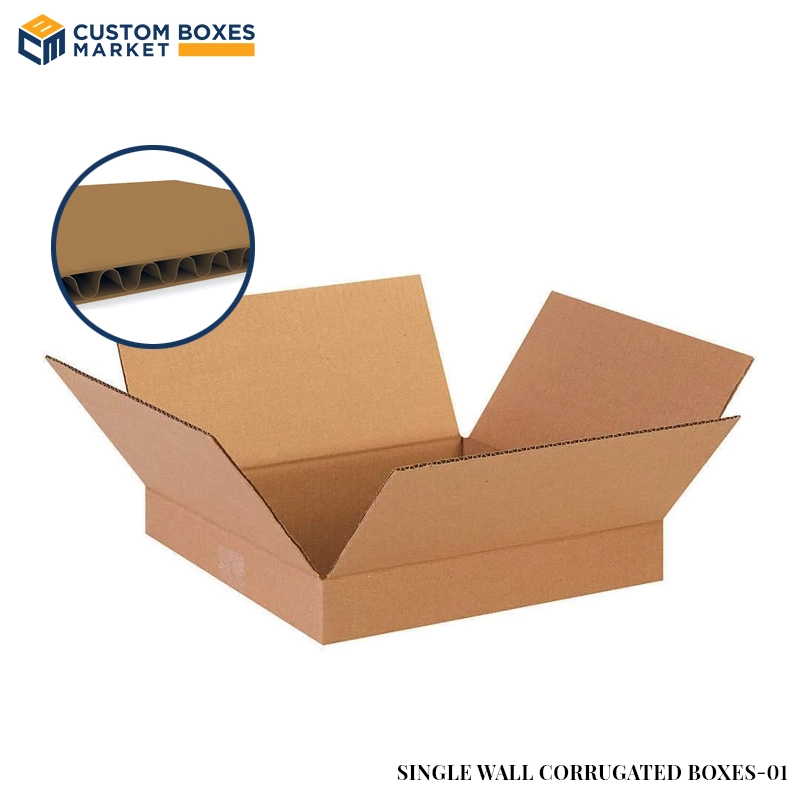

- Material: The type of material you are using such as paperboard, corrugated material, kraft, or rigid

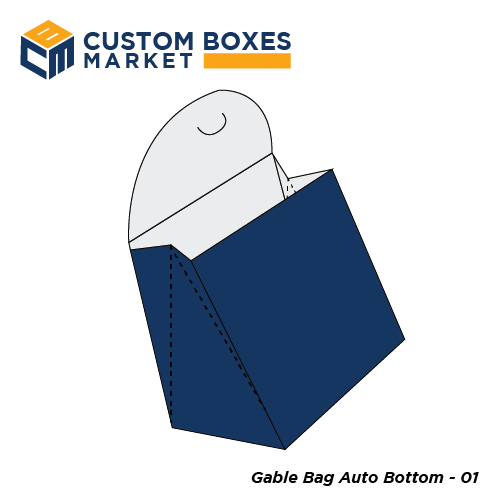

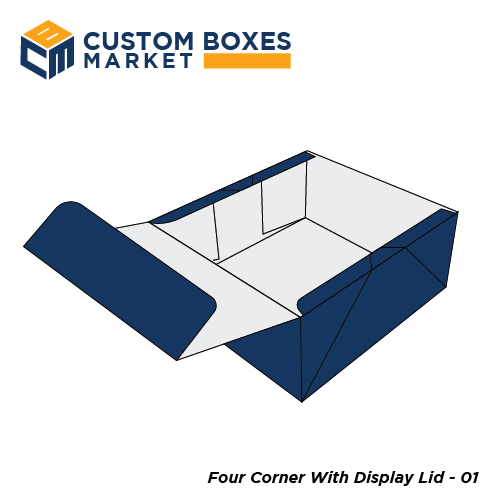

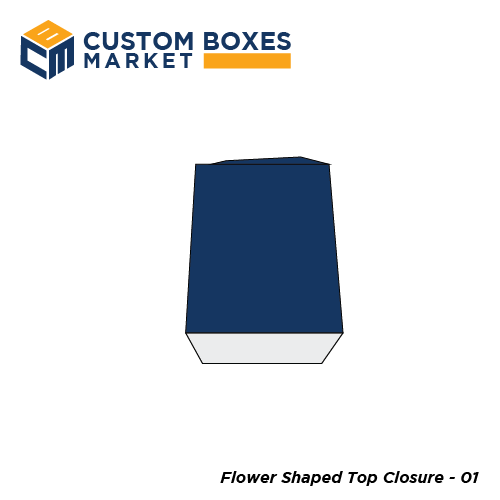

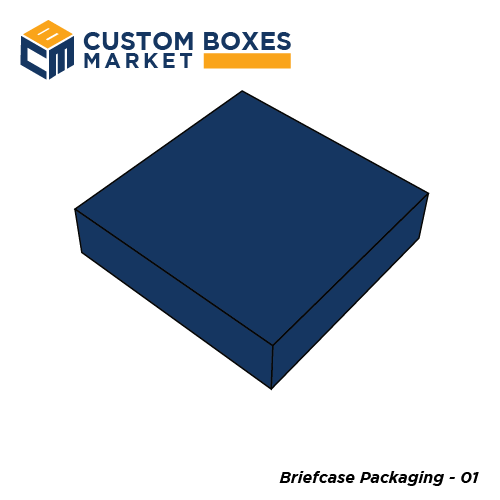

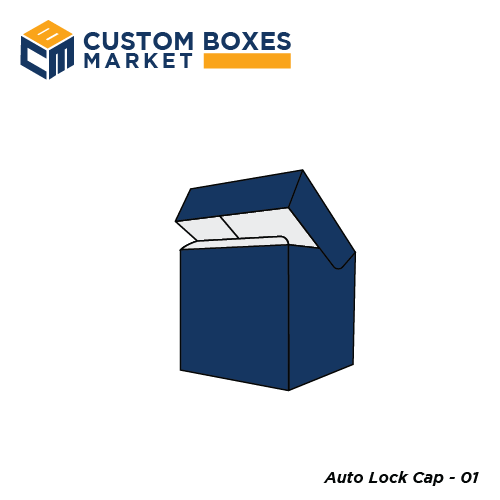

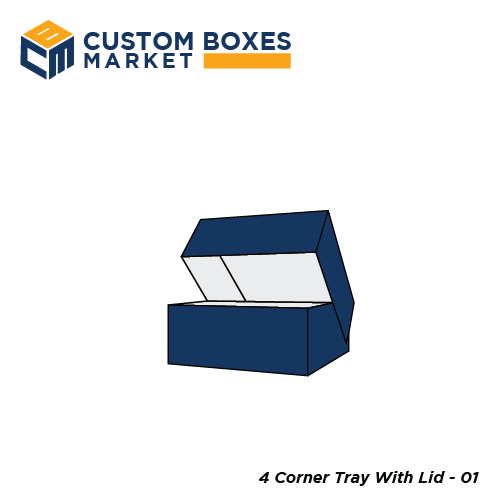

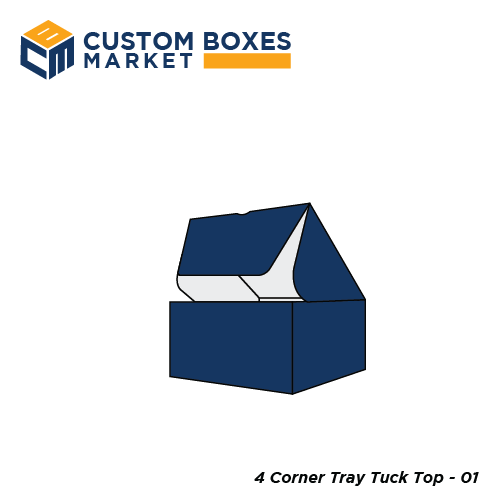

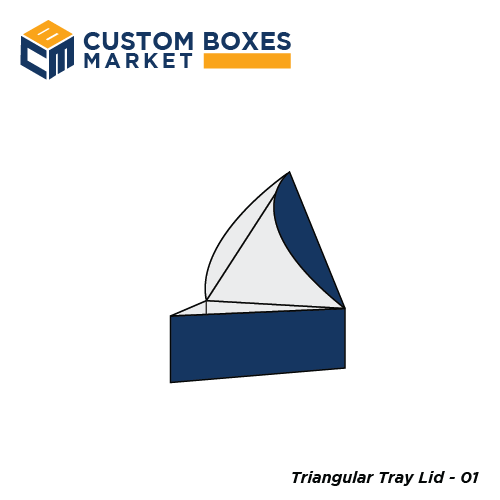

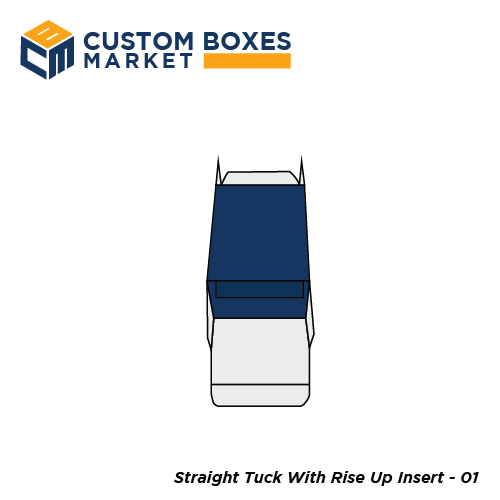

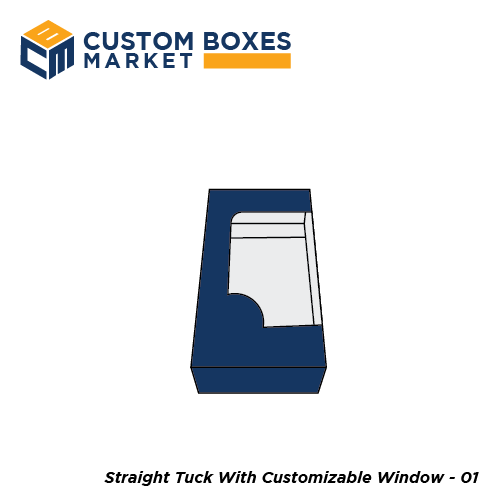

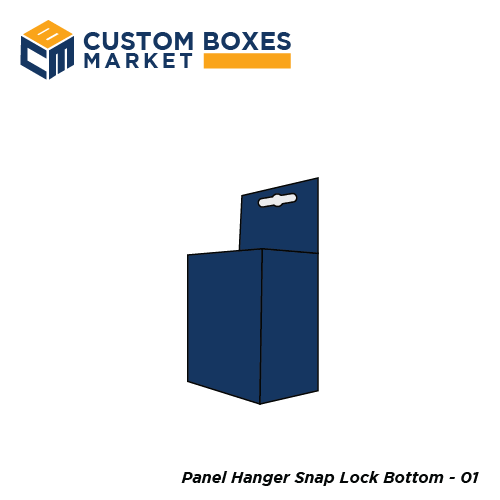

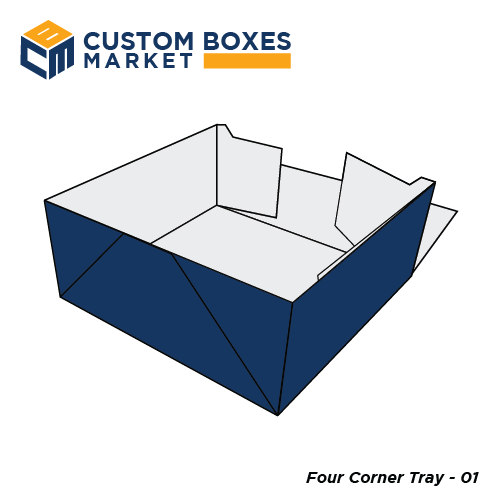

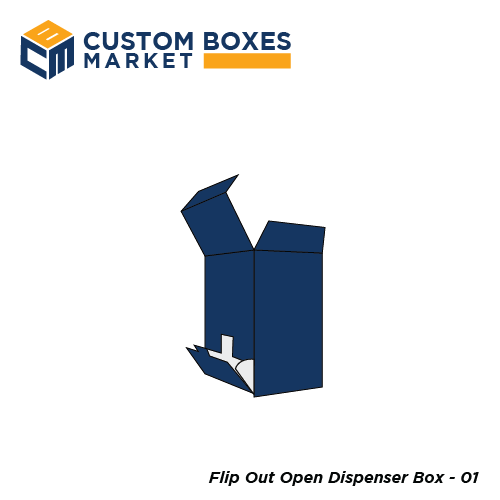

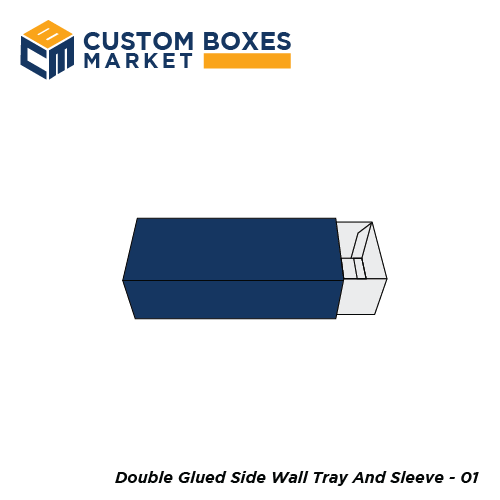

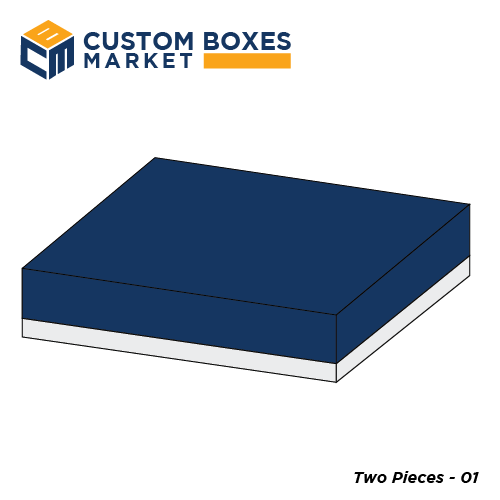

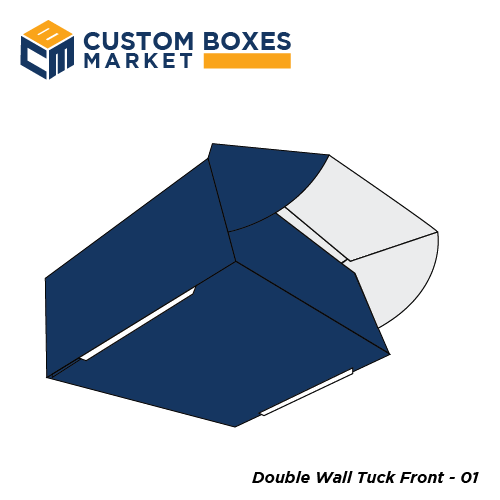

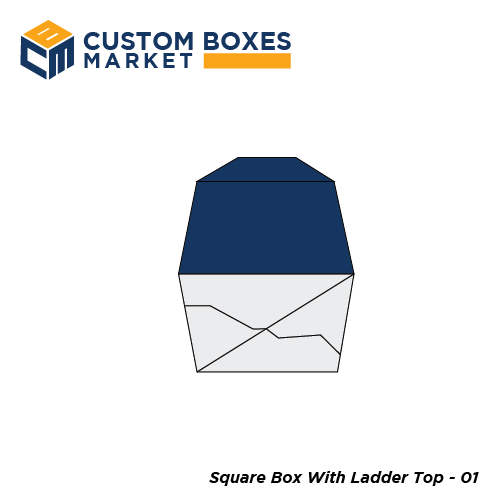

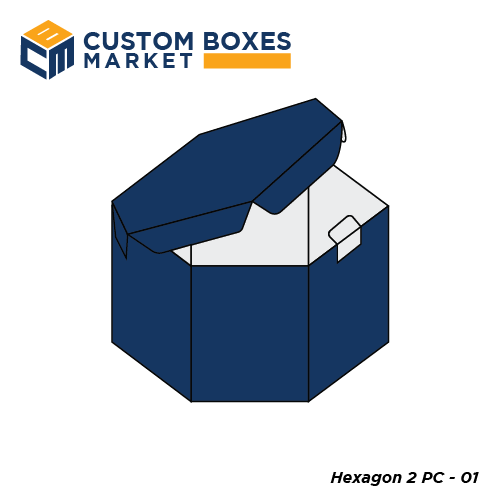

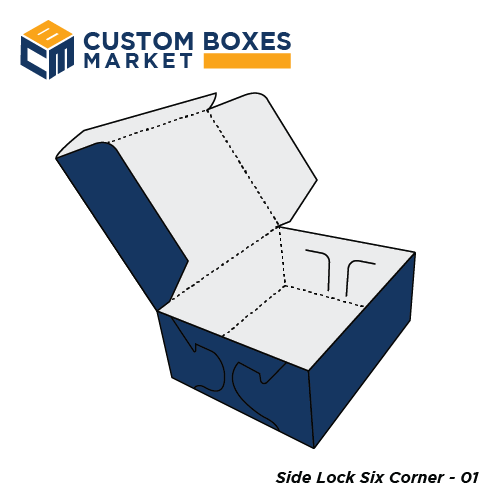

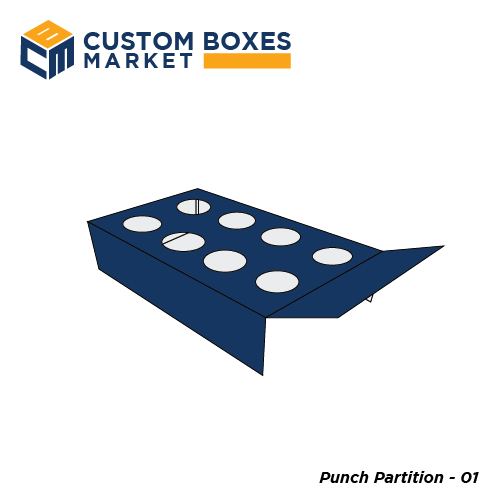

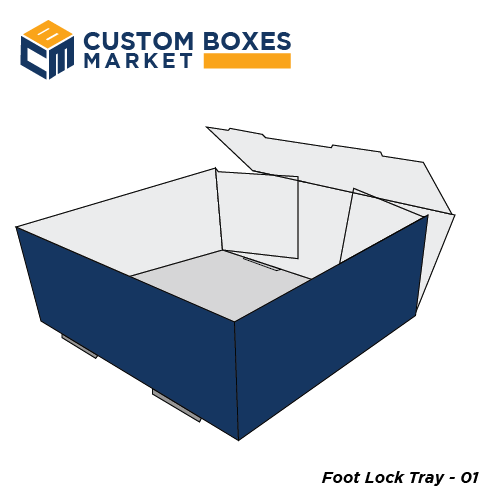

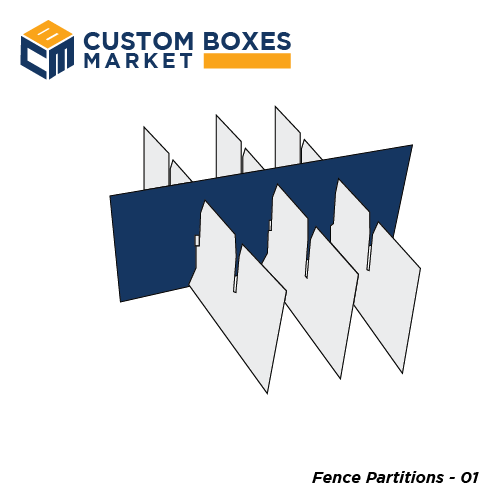

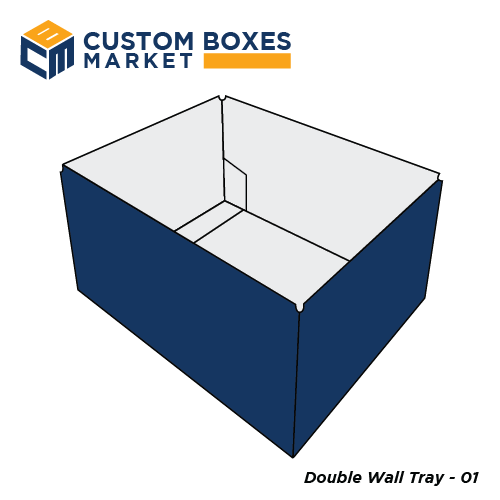

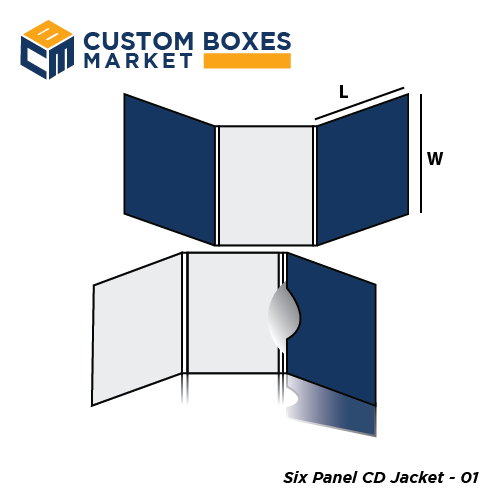

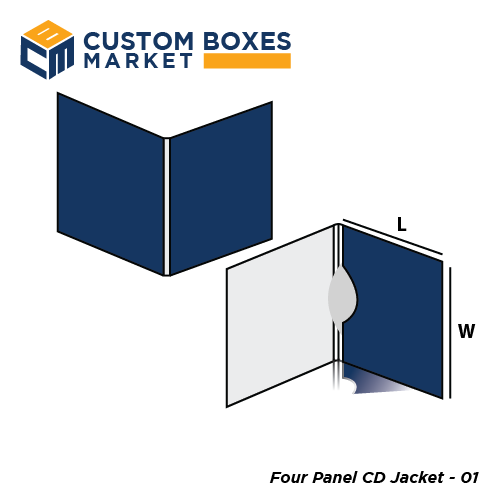

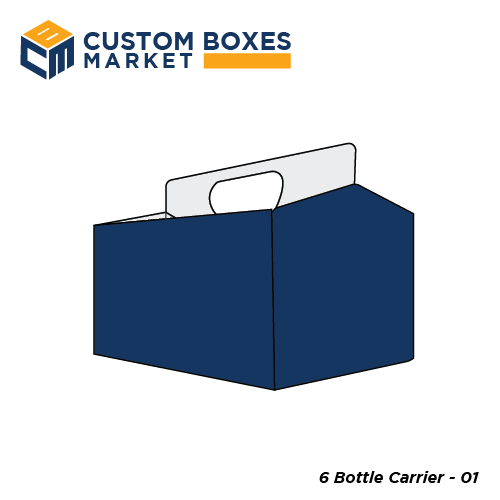

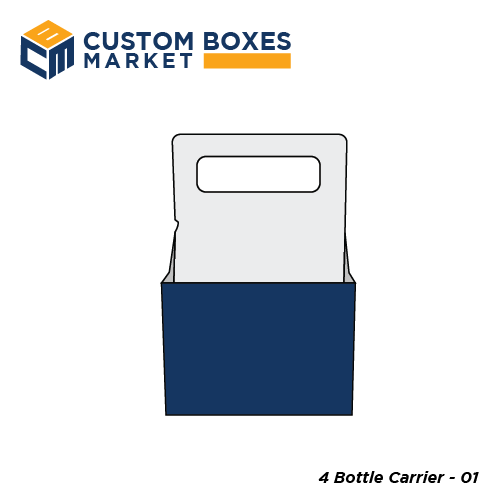

- Packaging Type: This includes your desired box style such as tuck-end boxes, sleeve boxes, etc

Use Design Software

Today due to the advancement in technology design software is there that has made the whole process easy and perfect. Mostly software such as Adobe Illustrator is used to create a dieline as it is precise. In it we have to follow the below-mentioned steps:

- Open the software and set up a new document. Inches or millimeters are used for the correct dimensions. Here the bleed area is also set that go beyond 3 – 5 mm of the actual trim size

- Creation of bleed lines and safety margins

- After the setting of dimensions, we draw the basic shape of the box using a pen or tool. You can use solid lines for cut lines and dashed lines for folds. You can extend the bleed line which is essential to ensure that the design covers the entire surface of the custom packaging boxes without leaving any white edges

- You have to draw a safety margin inside the dieline that will indicate the area where the critical design elements should not cross. This is necessary to prevent the cutting of your alluring design For additional perfection, you can label each section to avoid confusion at the time of box assembly such as front panel, side panel, top panel, etc.

Cross Checking

Double-check the measurements considering product specifications. You can use a simple paper to get a physical mockup to see the precision of your box dimensions. If the dimensions are correct then remove any unnecessary marks and correctly label the folds. Then you can lock the dieline layers to prevent any accidental change as it may cause you or your client severe loss and a certain debranding to your packaging company.

Importance of a Dieline

Die-making is one of the most crucial components that is used to get accurate custom packaging boxes. It helps you avoid any kind of misalignment or improper fitting of the box. It is a clear communication tool between the designers, printers, and manufacturers and keeps everyone on the same page. Moreover, dieline helps you prevent waste generation by reducing errors. You can get an identical copy of your design without spending a huge amount.

What Are The Different Types Of Die Cutting Machines?

In the packaging industry, different types of cutters are used depending on the type of materials. For instance, if your material is hard then you have to use metal cutters that are very sharp and protected with plastic or foam. For labels or to make the whole process fast there are different options, let’s discuss some of the types that are used in the custom boxes market:

-

Rotary Die Cutters

Here cylindrical dies are used to cut the materials. It is a fast process and perfect for manufacturing hundreds of boxes and custom labels at high speed. Moreover, in rotary die cutters, you can precisely and repetitively cut the materials. Rotatory die cutters are efficient for long runs, accuracy, and high-volume production.

-

Flatbed Die Cutters

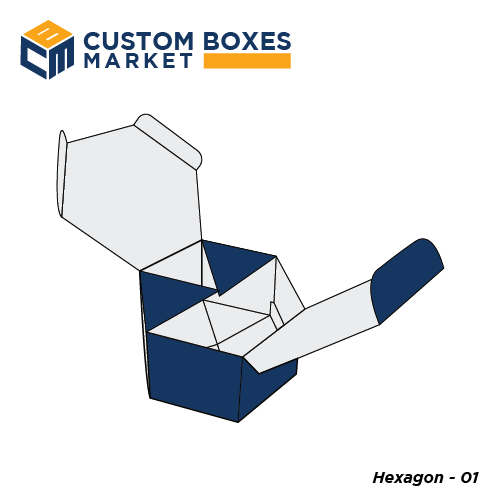

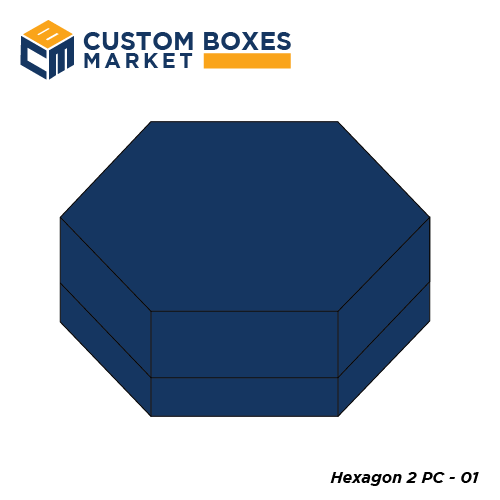

In flat die cutters, a flat die plate is used to cut the materials. If our customer needs rigid boxes then we prefer this die-cutting option. Nonetheless, it is a useful option when you need smaller runs but you can easily get complex shapes of the boxes like hexagon boxes. This option is also highly precise and useful for versatile materials

-

Laser Die Cutters

As the name of the cutter indicates, in this machine laser beams are used to cut or engrave materials. You can easily create complex designs at high precision with detailed patterns. If a customer needs a prototype, then laser die cutters are used as no physical dies are required in this method.

-

Digital Die Cutters

Like digital printing, we have the flexibility of changing designs, in the same manner, digital die cutters are an ideal option when you need design flexibility. If a customer wants a small order in a short duration then a digital die cutter is a good option, but for longer runs it is not feasible as the cost per unit will be higher, and it can also be not used for hard materials

-

Steel Rule Die Cutters

Steel rule ie cutters are used for hard materials and in them, the steel cutter is embedded into a wood, foam, or fiber for safety. You can cut materials like cardboard, corrugation, and rigid material with ease, or you can stacks of thinner material with precision at the same time. This is an ideal option for medium runs and different shapes like custom triangle boxes.

-

Rotatory Die Cutters With magnetic Cylinders

In it, flexible dies are present on the cylinders to cut materials at high speed. Specifically for labels where less downtime for die changing is required. It is also an accurate method to generate identical product packaging in bulk.

-

Punch Press Die Cutters

Mechanical pressure is applied on the dies so that the material can be cut down into various shapes. You can easily cut heavy-duty materials using punch press dies with larger cutouts. This die cutter has high cutting force and is also a durable option for custom box manufacturing.

-

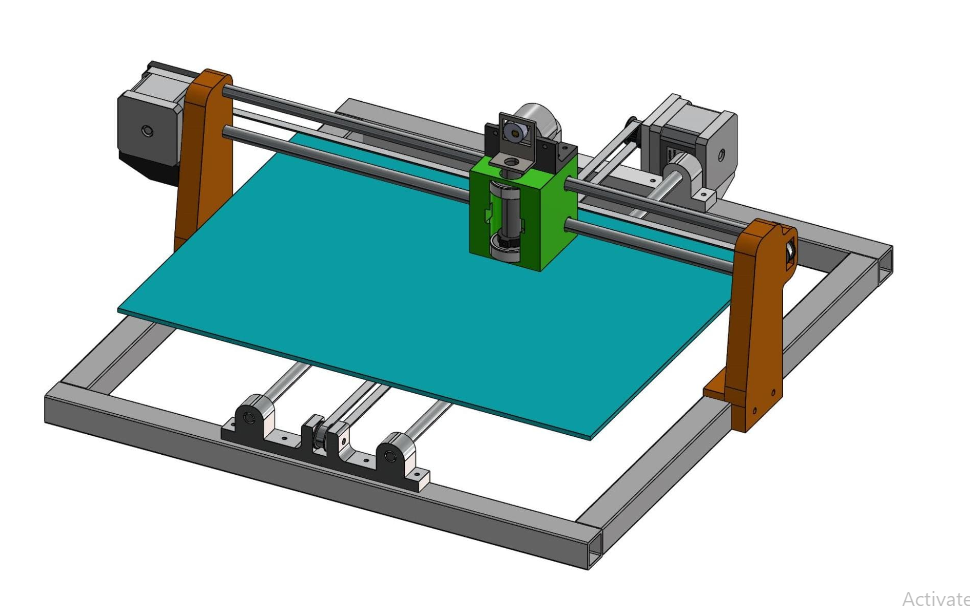

Plotter Cutters

This die cutter uses a plotter that guides a cutting blade around the material as per the commands according to the digital designs. It is also a good option to manufacture prototypes and short-run packaging. Here you do not need any kind of physical dies so it is also an economical option.

-

Kiss Cutters

Kiss cutters cut the top layer of the materials without cutting the backing material which is why it is used mainly in the manufacturing of custom stickers and labels. You can precisely control the cutting depth of your adhesive products like labels, or various types of stickers.

Conclusion

Dieline is one of the most useful steps in the creation of custom boxes. Brands spend so much to get a specific style, shape, and design of their packaging, and to make sure the customers get what they desire, the use of die lines becomes essential. There are various types of die-making machines based on the material and product you can select the method considering these aspects.

At our company, you can get diverse die-cutting options with precision and without much investment. So place your order of custom boxes at CustomBoxesMarket and enjoy any style, size, and shape of the boxes with sheer accuracy.

Categories

Recent Posts

16 / February , 2026 Box Material

3 / February , 2026 Gift Boxes

26 / January , 2026 Gift Boxes

6 / January , 2026 Sustainable Packaging

3 / December , 2025 Packaging Stats

17 / November , 2025 Custom Packaging

14 / November , 2025 Product By Industry

4 / November , 2025 Shipping Protection

28 / October , 2025 Custom Packaging

9 / October , 2025 Custom Packaging

7 / October , 2025 Shipping Protection

24 / September , 2025 Custom Packaging

18 / September , 2025 Custom Packaging

Get Free Quote

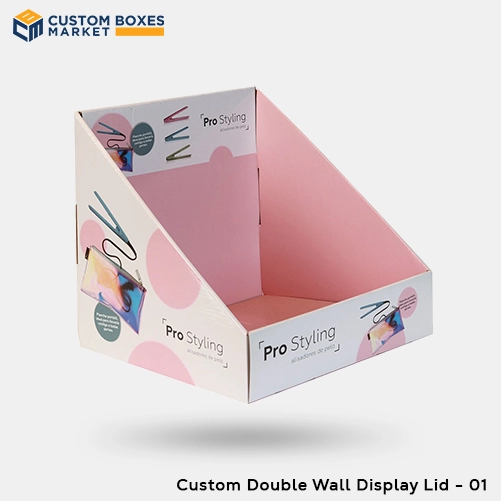

Related Products