What Makes Packaging Greaseproof, Waterproof, Or Food-Safe?

November 4, 2025 Shipping Protection

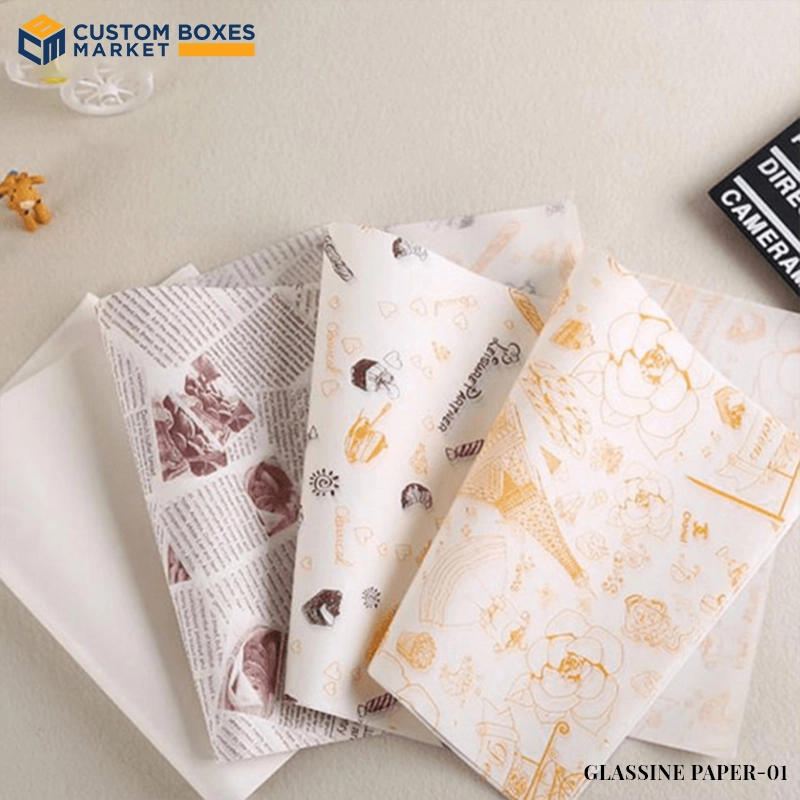

Would you want to serve your food in wrapping papers that are not only soggy but also oil is dripping from them? The customers would definitely not be tempted to try it. But the good news is that this problem can easily be solved with grease and water-resistant wrappings. You can also get food-safe packaging to make sure that the food remains healthy. So, let’s find out what makes a packaging grease and waterproof along with being safe for food contact.

What is Food-safe Packaging?

This thought must have crossed your mind at least once when you’re eating a sandwich wrapped in a paper that is this material safe for my food. Well, to address your query, there is a category of packaging that is called food-safe packaging.

What is FDA Certification?

There are various regulatory authorities like the Food and Drug Administration which provide guidelines that determine the food-safety of the packaging. Packaging can only be trusted for direct contact with food when these standards are followed properly. FDA-approved materials don’t let any harmful chemicals reach into your food. They also help maintain its freshness while making sure what you eat is as safe as it is delicious.

Which is the Best Material to Use?

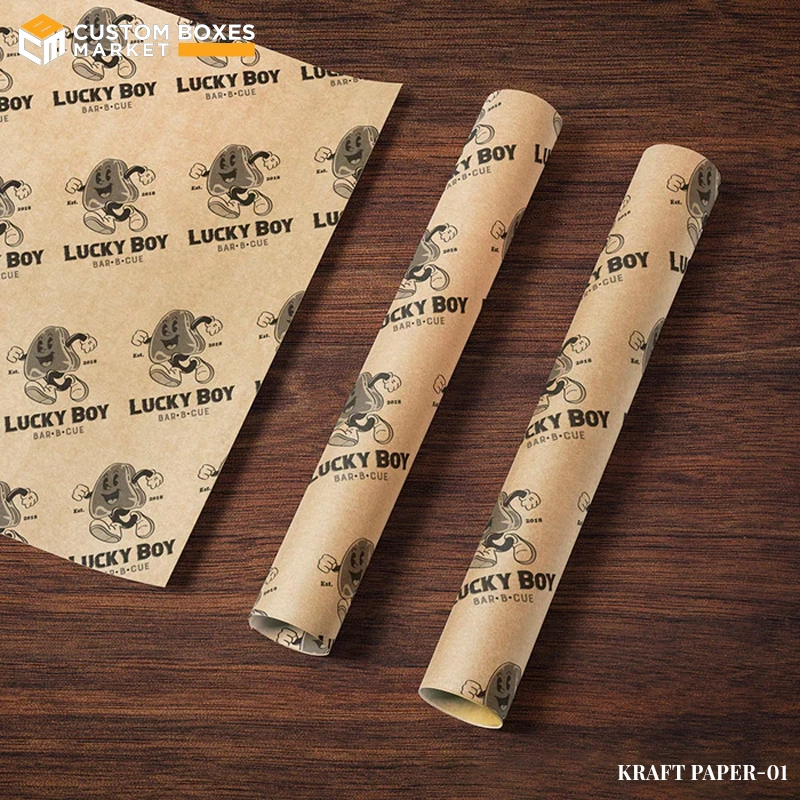

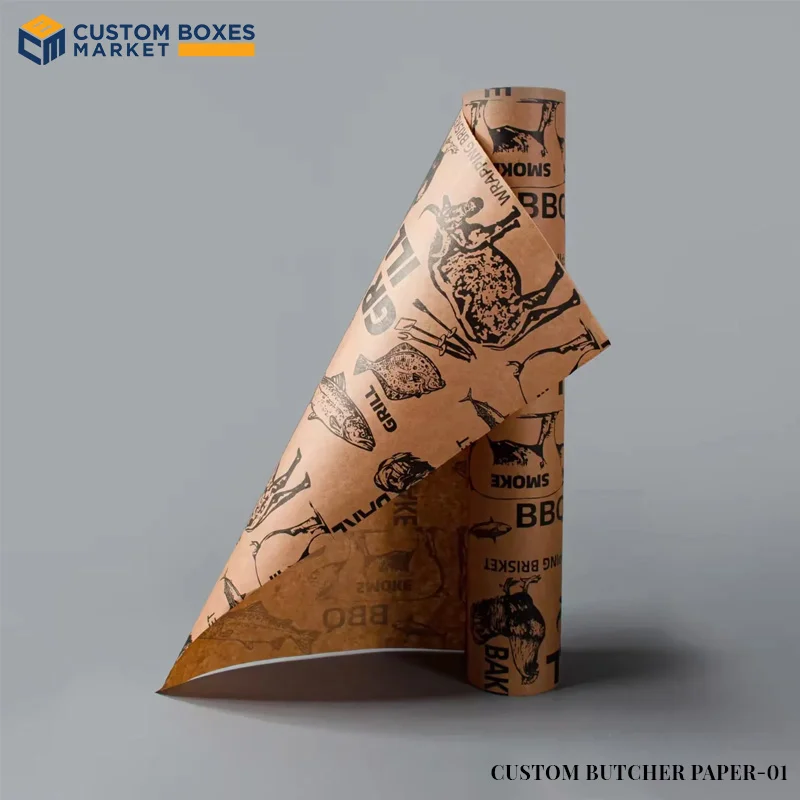

The material from which the packaging is made is of utmost importance. The most commonly preferred material for manufacturing food paper is Kraft. This material is biodegradable as it originates from wood pulp. The natural brown color of Kraft makes the packaging look aesthetic. You can also get it bleached if you want Kraft in white color.

The food-safe material must also be free from chemicals like Bisphenol A as they release plastics when they come in contact with heat. Such materials are unsuitable for packaging for food items because they can cause serious health issues.

Are inks used for printing safe?

Custom packaging is becoming popular day by day. Brands add a logo to their packaging to personalize it. Different designs in various colors are printed on food papers. The printing inks must also be safe for coming in contact with the food. Commonly the following options are considered for generating safe and alluring prints:

- Water-based inks

- Soy-based inks

These inks are food grade as they do not impact the quality of food. They are not only toxin-free but also have low VOCs which makes them an environmentally friendly option too.

How to Make the Packaging Greaseproof?

Greaseproof packaging is a type of packaging that has the ability to resist fats and oils coming out of the food. Without it, the food paper becomes greasy and difficult to handle. Grease also leaves stains on the packaging that reduce its visual appeal to a great extent.

What processes are involved in manufacturing greaseproof packaging?

There is a complete process to manufacture greaseproof paper. This includes:

-

Pulping

In this step, the wood fibres are crushed into small units to increase their surface area.

-

Paper making

The pulp then undergoes a dehydration process where water is removed to give strength to the paper.

-

Supercalendering

The paper is subjected to high pressure by being passed through rollers. Porosity of the paper is reduced in this process because the fibres are bonded tightly to each other, due to which it begins to repel oils.

-

Surface treatments

To enhance grease resistance, the packaging is coated and exposed to sizing agents.

-

Drying and Cutting

The paper is then dried out completely and cut into the required shapes, depending on the brand’s preference or the size of the food products.

What is Parchmentizing?

Parchmentizing is a process that makes food paper greaseproof and heat-resistant without needing plastic. The steps include:

-

Acid Treatment

The process starts with dipping the paper made of wood pulp in mild acid solutions like sulfuric acid.

-

Densification

These acids partially dissolve the paper’s surface. By doing so, they allow the fibres to bond more tightly and make the paper dense.

-

Neutralization:

Water is used in the next step and an ammonia bath is given to the paper to neutralise the acid.

-

Drying

The treated paper is then dried to remove moisture to obtain the final product.

Why is Waterproof Packaging Important?

Ever had packaging fall apart because of high moisture content? Whether it’s a cold drink cup or moisture can ruin the packaging and the product inside. This is where waterproof packaging comes in. It keeps the product safe from unwanted dampness by resisting moisture.

Is Waterproof Packaging Only for Food?

Water-resistant packaging is not reserved for food only. There is a wide range of products that require being kept away from water to be fully functional. Take the example of bath bombs. They fizz up instantly and crumble if they come in contact with water prior to their use. Waterproof packaging protects the packed product from being damaged.

How can packaging be made resistant to water?

There are a number of ways in which a package can be made waterproof. These include:

-

Laminations

A plastic or foil can be used to give the packaging water-resistant properties. These are particularly useful in wrapping frozen food as they have high moisture content.

-

Polymer blending

Synthetic polymers like Polylactic acid can be blended into the pulp itself instead of applying it after production before the paper or board is formed . This makes the material inherently water-resistant.

-

Structural designs

Water resistance can also be achieved by smartly designing the packaging. Zip lock bags and multilayered packaging can be used to physically stop the water from reaching the product.

Are Coatings Important to Resist Grease and Moisture?

Coatings play an immensely important role in making the packaging resistant to grease. There are multiple coating options, out of which some are listed below:

-

Wax coatings

A wax coating creates a protective layer between the food and its packaging. It helps to block oil as well as moisture. But it cannot be placed in ovens because it can’t withstand high temperatures.

-

Polyethylene coating

It acts as a protective layer that not only prevents grease from spoiling the packaging but also does not allow moisture from coming in contact with the food.

-

Polylactic acid

This is a bioplastic derived from plant sources. It is a great option to make packaging greaseproof, but it is not advisable to expose it to very high temperatures.

-

Silicone coating

Silicone grants nonstick properties to the packaging. It repels moisture and grease effectively.

-

Sizing agents

Their versatility makes them an excellent option. They improve the strength of the packaging by making it water repellent.

Final Remarks

The right packaging makes all the difference. It is responsible for protecting and preserving the quality of the product. CustomBoxesMarket creates packaging that adds value to your brand. You can get a packaging that is all greaseproof, waterproof and food-safe together. These qualities ensure that your product is safe and hygienic and guarantee the best customer experience ever possible.

Categories

Recent Posts

19 / February , 2026 Box Customization

16 / February , 2026 Box Material

3 / February , 2026 Gift Boxes

26 / January , 2026 Gift Boxes

6 / January , 2026 Sustainable Packaging

3 / December , 2025 Packaging Stats

17 / November , 2025 Custom Packaging

14 / November , 2025 Product By Industry

4 / November , 2025 Shipping Protection

28 / October , 2025 Custom Packaging

9 / October , 2025 Custom Packaging

7 / October , 2025 Shipping Protection

24 / September , 2025 Custom Packaging

Get Free Quote

Related Products